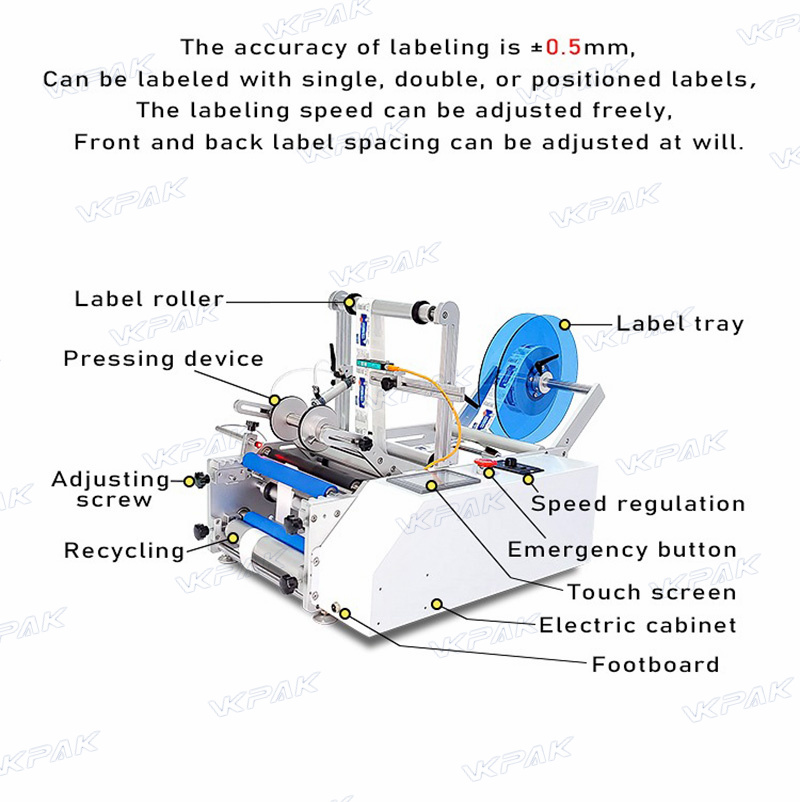

VK-T801 Semi-Automatic Round Bottle Labeling Machine

$1,800.00

Tax included. Shipping calculated at checkout.

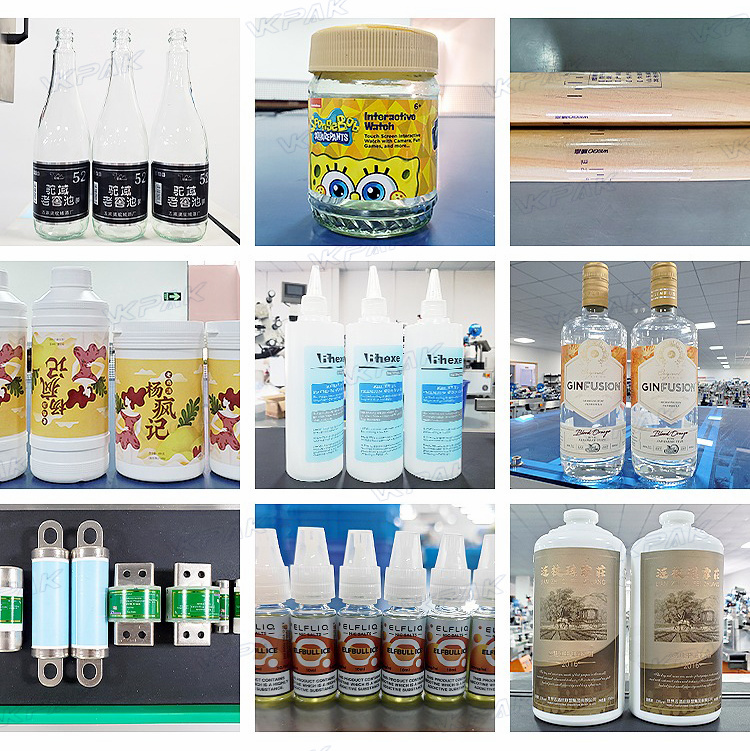

Suitable for all kinds of cylindrical objects labeling,small taper round bottle labeling, such as xylitol, cosmetics round bottles, wine bottles, etc. Can achieve wrap around labeling, front and back labeling, label’s distance can be adjusted.

Widely used in food, cosmetics, chemical industry, vintage, medicine and other industries.

Optional positioning detection function by which you can label to specified location in the circumferential surface.

Optional ribbon coding machine and hot stamp printer,can be added to the labeler head,can print MFG, EXP and LOT on labels at the same time while labeling,greatly improve production efficiency.

View Video Download PDF

Description

| Technical Parameters | The following are the technical parameters of the standard model, if have other specicl requirements and functions can be customized |

| Labeling Accuracy | ±0.5mm |

| Labeling Speed | 15-30 pieces/min |

| Applicable for product diameter | 10mm-150mm |

| Applicable Label Size | Length: 20mm-300mm Bottom paper width :10mm~230mm |

| Device Dimensions | 913mm*495mm*502mm |

| Applicable Power Supply | 220V/50HZ |

| Weight | 34KG |

| Applicable Label Roll lnner Diameter | 76mm |

| Applicable label Roll lnner Diameter | 280mm |

Basic Applications

- Using the roll-on method, labeling on cylindrical objects of various specifications and small taper round bottles, such as beverage bottles, cosmetic round bottles, wine bottles, etc.

- It can realize full-wrap/half-wrap labeling, labeling on the front and back of round bottles, and the spacing between the front and back labels can be adjusted arbitrarily. It is widely used in food, daily chemical, pharmaceutical and other industries.

- Support conical bottle labeling, with taper adjustment knob, simple adjustment can meet conical bottle labeling.

- Circumferential/semi-circle positioning detection device is optional to realize high-precision positioning and labeling of circumference/semicircle

- It can be equipped with a coding machine, which can print the production date and batch number and other information at the same time of labeling to realize the integration of coding and labeling.

Scope of Application

- Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, bar codes, etc.

- Applicable products: products requiring labels to be affixed on the circumferential surface and conical surface can be affixed with single label or double label.

- Application industry: widely used in food, medicine, daily chemical, electronics, hardware, plastic and other industries.

- Application examples: Oral liquid round bottle labeling, vial labeling, xylitol labeling, shampoo bottle labeling, wine double labeling, fixed point labeling and back labeling, etc.

Work Process

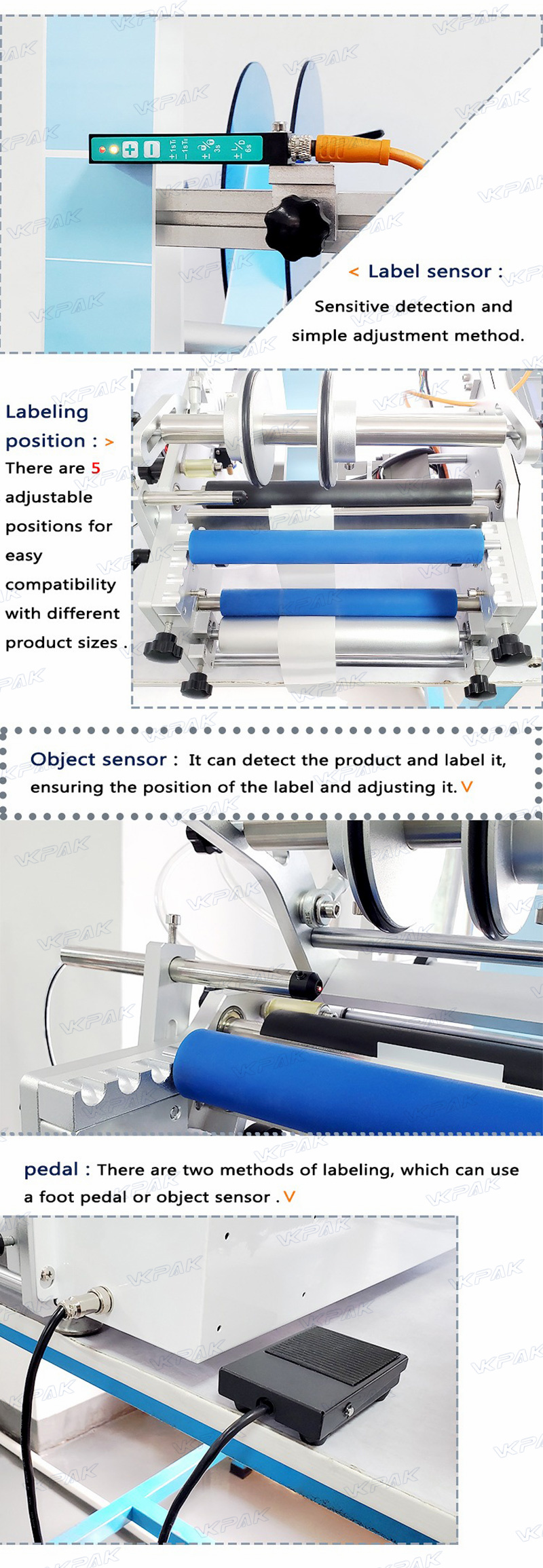

- Core working principle: the sensor detects that the product is in place or the foot is stepped on to signal that the product is in place, and the suction head sucking the label goes down to apply and press the label, and then returns to home position to absorb the next label, wait for the next labeling signal, and the applying of a label is completed.

- Operation process: place the product – make sure product in place (equipment detection control or manual control) – apply and press label (automatically realized by the equipment) – take out labeled product

Features

- Powerful function: It can be used for labeling of cylindrical objects of various specifications, small taper round bottle labeling, and can realize full-wrap/half-wrap labeling, and labeling on the front and back of round bottles.

- Accurate labeling: high stability, using PLC + subdivided stepping motor to drive the label delivery, accurate delivery; the feeding mechanism is equipped with a brake function to ensure that the label is tensioned to ensure accurate label detection; the label tape bypasses the deviation correction mechanism to prevent the label from shifting left and right.

- Durable: The electrical and the pneumatic circuits are arranged separately, and the pneumatic circuit is equipped with a purification device to prevent the moisture in the air from invading the electrical appliances and prolong the life of the equipment; the whole machine adopts high-grade aluminum alloy and stainless steel materials, solid quality.

- Easy to adjust: It is equipped with the function of adjustable spacing and stroke, and labels of different sizes of products, without the need to repeatedly replace the jig.

- Beautiful appearance: The bottom-mounted computer white electric box, with stainless steel and high-grade aluminum alloy, is beautiful and elegant, and improves the equipment level.

- There are two labeling control methods: manual/automatic: workers can choose to use sensors or foot pedals to achieve labeling control according to their needs; set manual and automatic control button, the length of the label dispensed can be adjusted arbitrarily

- Optional functions and components: ①Hot coding function; ②Special label sensing electric eye.

Label Making Requirements

The following is the label making method of the labeling machine:

- The interval between label and label is 2-4mm.

- The distance between the label and the edge of the bottom paper is 2mm.

- The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper).

- The inner diameter of the core is 76mm, and the outer diameter is less than or equal to 250mm, arranged in a single row.

1 review for VK-T801 Semi-Automatic Round Bottle Labeling Machine

You must be logged in to post a review.

Bernie –

I bought this machine from VKPAK and used it for several of my bottles. It is a good machine.