VK-UTS-003 Semi Automatic Linear Ultrasonic Tube Sealing Machine For Monodose Strip Tube

$3,800.00

Tax included. Shipping calculated at checkout.

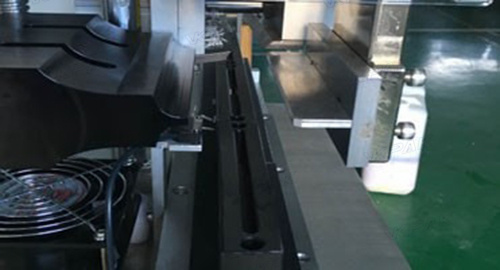

The VK-UTS-003 semi-automatic tube sealer is the latest technology in small to medium sized tube sealing. It combines ultra-sonic sealing, batch stamping, trimming and a corrugated cosmetic / pharmaceuticals grade finish. This machine requires an operator to load the tube pucks and move the tubes through the stations. Capable of running up to 15 units per minute this machine works perfectly with one of our bench top fillers and labellers.

Sealing Method: Ultrasonic Sealing

Output Speed: 10-15 pieces/min

Dimension: L560*W537*H880mm

View Video Download PDF

Description

This machine is designed to produce perfectly sealed tubes that look to have been manufactured on a much larger more expensive fully automatic machine. Featuring all the modern components and functions of state of the art automated machinery, this small portable tube sealer is all any SME business needs and can be operated by anyone with very basic instruction.

Manufactured from 316 stainless steel this machine is suitable for any food or pharmacutical application. Requiring a small air compressor and standard 10amp power point its easily connected and set up in any manufacturing location. This machine can seal any plastic and laminate tube material up to 57mm in diameter.

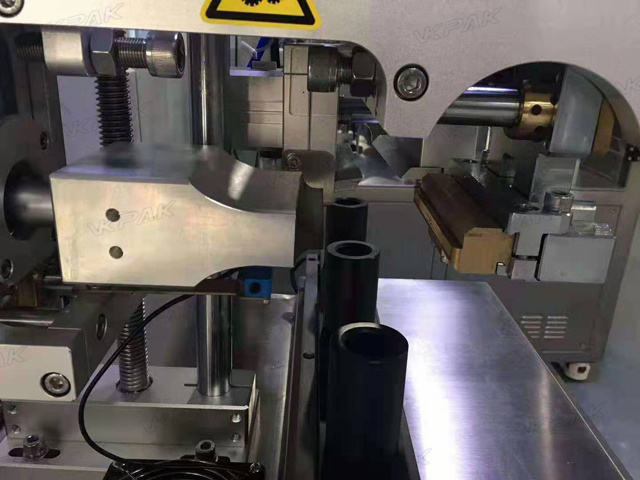

Special tube holding pucks can be supplied with the machine holding your tube perfectly straight during the sealing process, and a number/letter set can also be provided for batch stamping your unique batch number into your tubes.

Parameter

| Model | VK-UTS-003 |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Capacity | 10-15pcs/min |

| Sealing Dia. | 5-50mm (Custom-made available) |

| Tube Height | 50-250mm |

| AirPressure | 0.5-0.6MPa |

| Dimension | L560*W537*H880mm |

| N.W | 120kgs |

Application:

Widely used for food, pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube filling and sealing.

Features

Seal All plastic and laminate tubes, ANY shape or size

Production speeds of up to 15 tubes per minute

Date / Lot Coding of all tubes already built-in

Seals through product contamination

Very low reject rate, less than 1%

Ultrasonic sealing eliminates ‘flash’ and ‘ears’ versus hot-air sealing methods

Rotary cutting knife to cleanly cut even the thickest tube materials

Change-over time of less than 5 minutes

Virtually NO CHANGE PARTS

Line operators can setup and run machine, no mechanics required

Training new operators is literally a 10-minute procedure, extremely simple

Small footprint, table-top design

Perfect for small production runs and lab use

No warm-up time needed, plug in and it’s ready to seal tubes right away

No water requirement

Single phase, 110v power (no 3-phase power required)

Needs only a very small air compressor for air requirements

You must be logged in to post a review.

Reviews

There are no reviews yet.