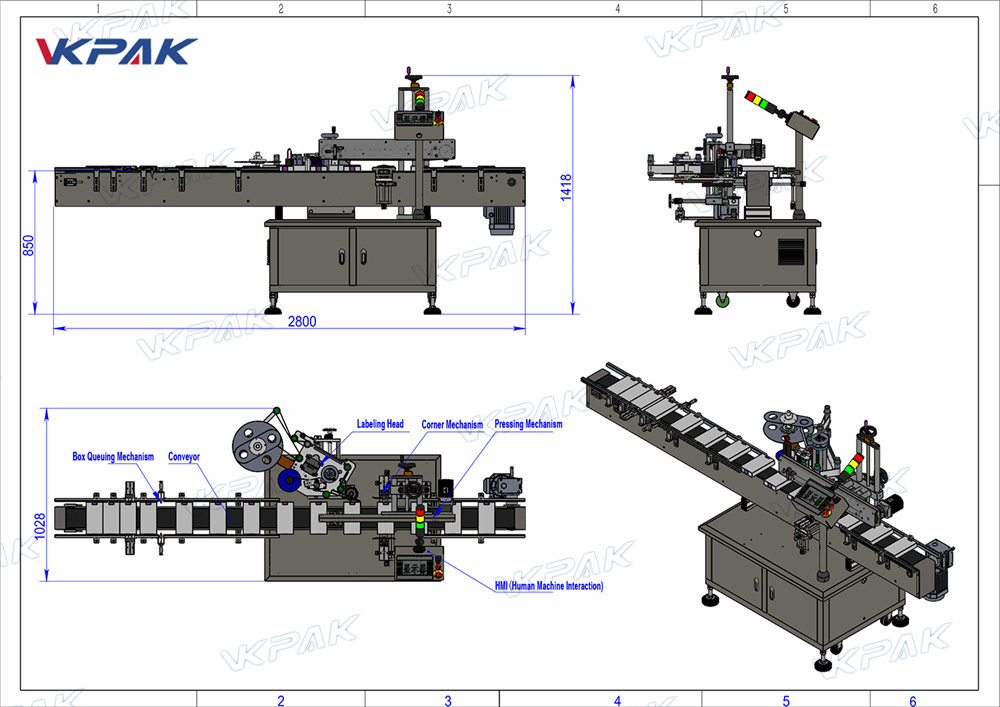

VK-BCL Automatic Carton Flat Box Tamper-Proof Corner Wrap Sticker Labeling Machine

$6,600.00

Tax included. Shipping calculated at checkout.

The model labeller is suitable for various sizes of folded and filled carton boxes, with single-sided or double-sided folded corners labeling. General labels, transparent labels, or other tamper-evident labels can be applied.

Designed for labeling stickers on box corner like security label

High working efficiency, it can label 50-200 pcs/min

Output Speed: 50-200 pieces/minute depends on label and product size

Dimension: (L)2800*(W)1150*(H)1450(mm)

View Video Download PDF

Description

Corner wrap Labeler is suitable for corner labeling for various carton box products.

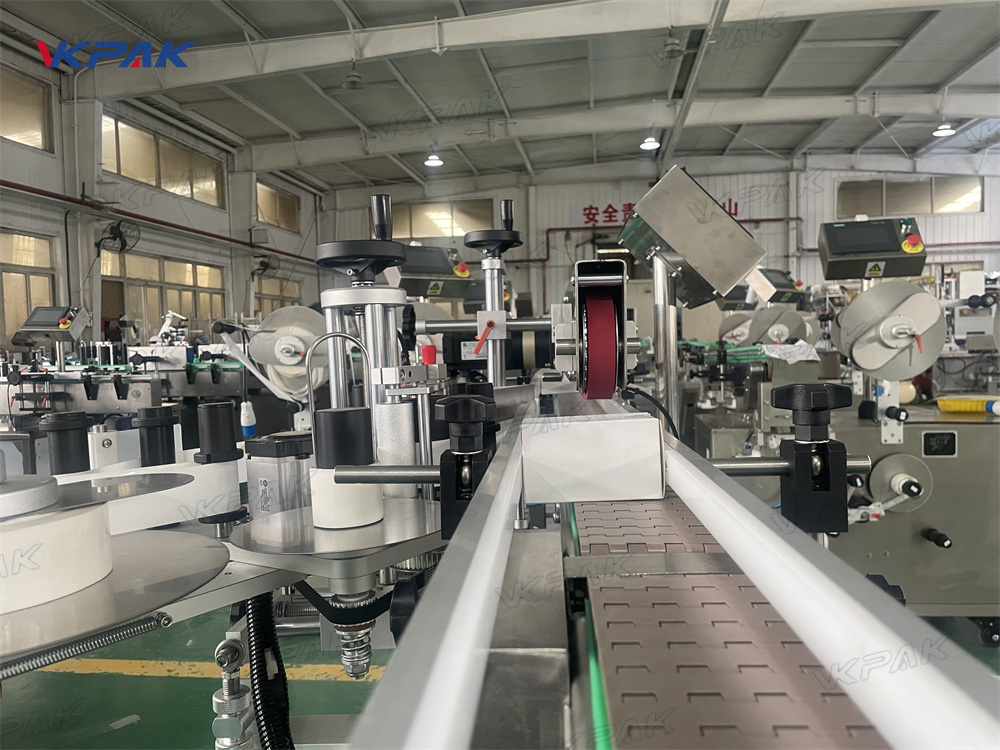

Corner wrap labeler is suitable for corner labeling for various carton box products. Adapt inline continuous labeling without product pause. Which is most suitable tamper-evident & corner labeling product within the market.

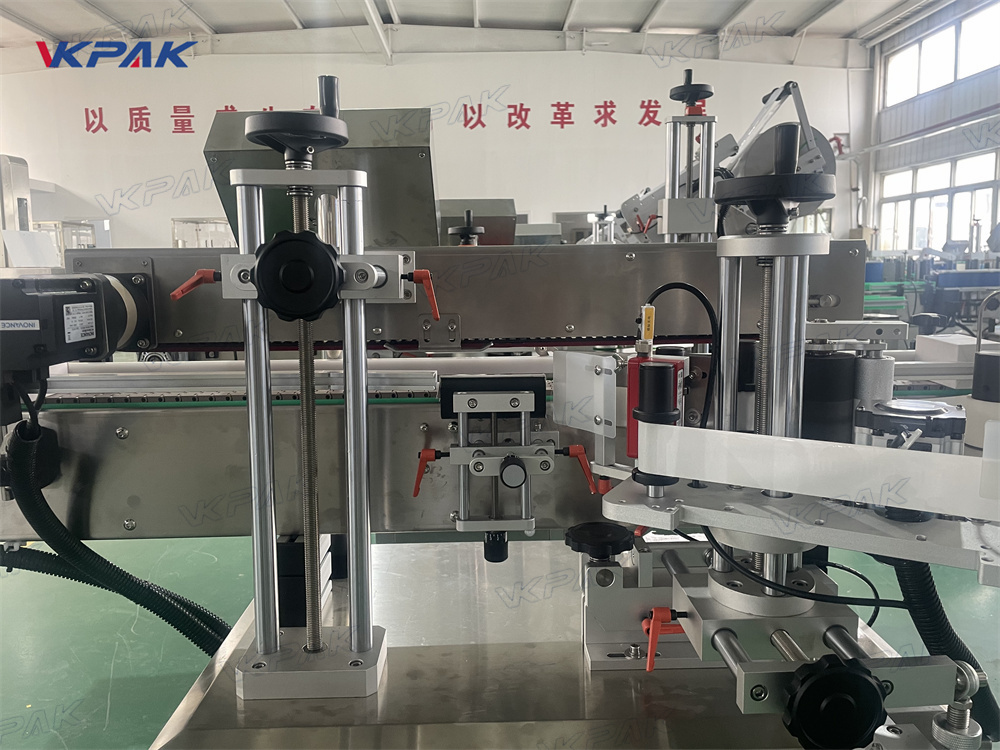

Well-designed structure efficiently adjusts applicator position and related assembly, complicated part changeover is not required.

Through touch screen will able to proceed detail and specific settings.

The corner wrap labeler is equipped with production quantity set and pre-count function for production monitoring purpose.

The seal labeling machine can able to customize equip various detection and warning function for the production management. To ensure labeling accuracy precision and meet strict quality demand.

Dedicated to box corner labeling, in the box on the plane and side plane corner labeling, play the role of anti-tampering. Mainly used in poker, electronic products, mask boxes and pharmaceutical boxes to prevent tamper-evident labels on both sides of the labeling.

Full-automatic corner labeling machine can be matched with plane labeling machine to form continuous labeling.

Paramenters

| Model | VK-BCL |

| Labeling Speed(pcs/min) | 50-200(related to bottle and label size) |

| Labeling Accuracy(mm) | ±1.0mm |

| Suitable Label Size(mm) | (L)15-300mm (H)20-130mm |

| Suitable Box Size | (L): 20-300mm, (W):20-200mm, H:20-180mm |

| Roll Inside Diameter(mm) | Φ76mm |

| Roll Out Diameter(mm) | Φ300mm |

| Machine Size(mm) | (L)2800*(W)1150*(H)1450(mm) |

| Power Supply | AC220V 50Hz/60Hz |

| Operation direction | left to right or right to left |

| Net weight | About 450Kg |

| Label material | self-adhesive sticker, opaque or transparent label |

Application

Main Configuration

| Name | Brand | Origin |

| Servo motor | Panasonic | Japan |

| Servo motor Drivers | Panasonic | Japan |

| Touch screen | Siemens | Germany |

| PLC | Siemens | Germany |

| Lable sensor | Leuze | Germany |

| optical fiber sensor | Omron | Japan |

| Low voltage electrical apparatus | Schneider | France |

| cylinders | Airtac | Taiwan |

| Conveyor motor | JSCC | Germany |

| frequency converter | Siemens | Germany |

| separate bottle device motor | JSCC | Germany |

It is complied with GMP standard that provides easy maintenance and for a long durable life.

The mobility castor and stainless-steel fixing nut are designed to flexibly move the machinery to support another production line to boost the invest benefits.

It provides a wide range adjustment ability by equipped with hand wheel mechanism for easy adjustment of applicator and depended on products.

Smart label length set to quickly achieve for perfect position of label by counter.

Missing label set prevents product miss-labeled to ensure product accuracy while production and fulfill production QC procedure.

A built-in counter can either run freely keeping track of the number of products labeled to control the production.

Production preset function that the labeler automatically stops when the desired numbers of products have been labeled for efficient production management.

Auto label start up mode while the power been switch on, the machine will enter labeling condition automatically as previous run without reset.

Labeling delay function that it is ideal for small scale adjustment and could do calculate digitally for dispensing speed and position.

You must be logged in to post a review.

Reviews

There are no reviews yet.