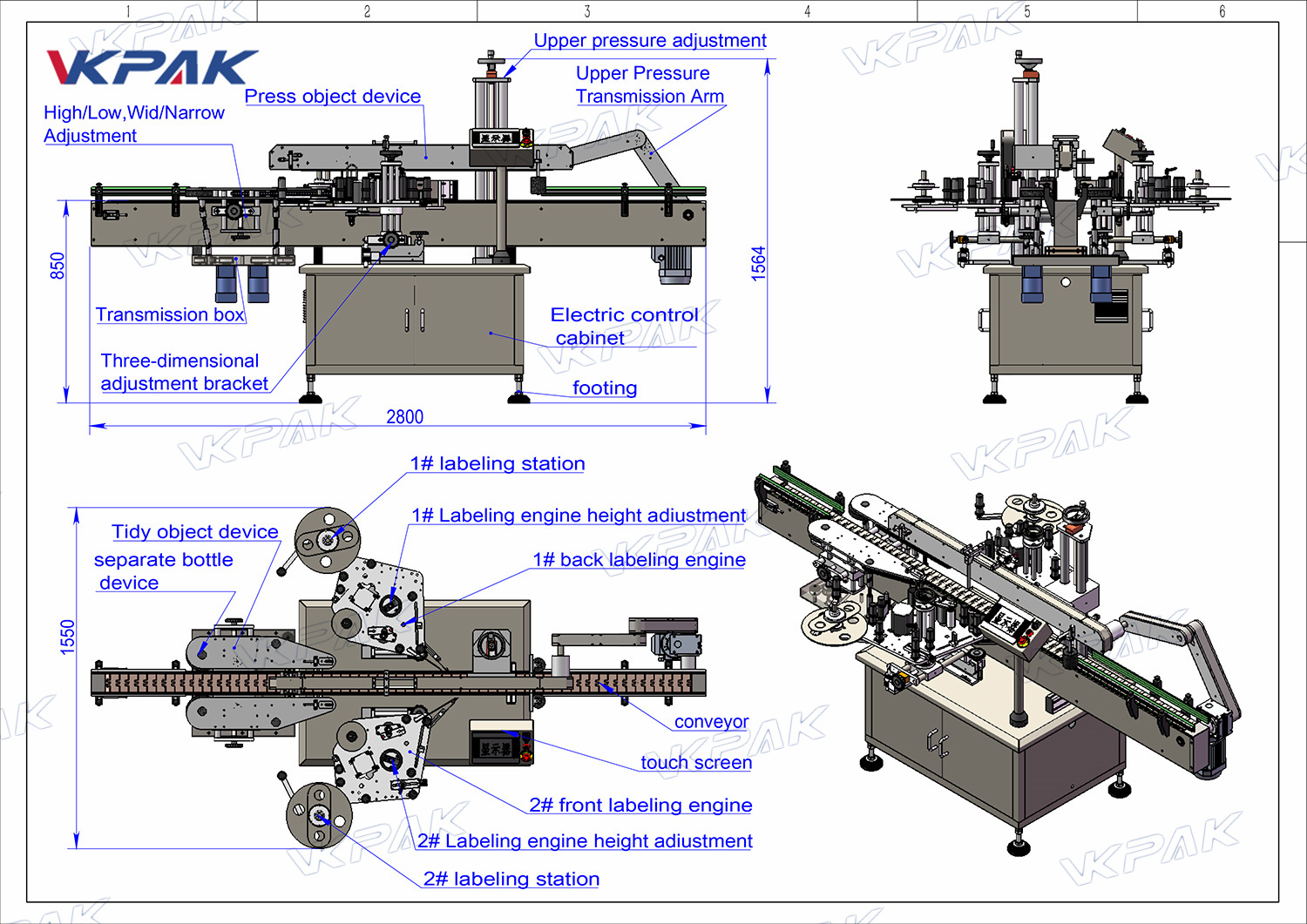

VK-DSL Automatic Square Flat Bottle Front Back Double Sided Sticker Labeling Machine

$10,500.00

Tax included. Shipping calculated at checkout.

The front back labeler is a computerized, versatile and dynamic front back tagging device specifically designed to meet the labelling needs of a wide range of industries. It offers superior quality and accuracy with its innovative labelling technology. The labeler is capable of printing labels of width 5-240mm at a speed of 1000-8000 bottles per hour. The device is fully automated and can be easily operated with its user-friendly control panel. The front back labeler is your perfect choice for efficient and high-quality labelling.

Output Speed: 30-180 pieces/minute depends on label and bottle size

Dimension: 2800(L)1300(W)1800(H)mm

View Video Download PDF

Description

This vertical type labeling machine is suitable for sticking labels on flat surface like square bottles, laundry detergent bottles, machine oil bottles, shampoo bottles, etc. It can be used for single side or double side labeling, improving work efficiency. This machine can be customized according to customers' need.

This machine can work with automatic filling machine and capping machine, realizing automated production. Please contact us if you need.

Technical Parameter:

| Model | VK-DSL |

| Capacity (PCS/min) | 30-180(depend on bottle and label size) |

| Conveyor running side | from left to right / from right to left |

| Conveyor speed(meter/min) | ≤40 |

| Labeling error | < ±0.5mm |

| The inner diameter of label roll | 76 mm |

| The outer diameter of label roll | 360 mm(max) |

| Suitable for label size | W:5-300mm, L:10-500mm |

| Suitable size of labeling objects | any size |

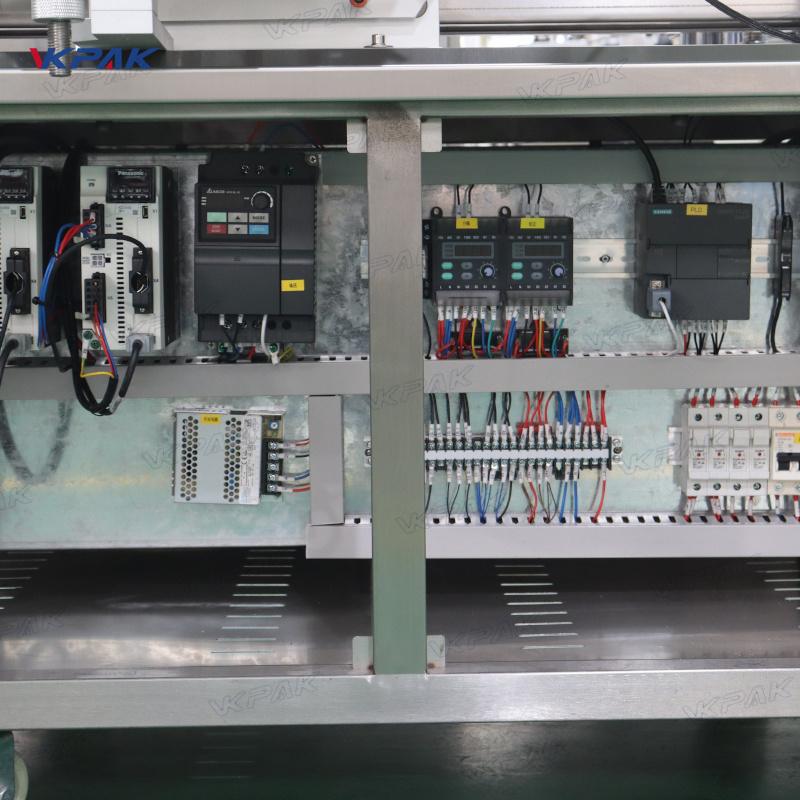

| Power supply(In China) | AC220V 50/60HZ single phase (customized) |

| Power | 1300W |

| Weight | 600 KG |

| Machine size | 2800(L)1300(W)1800(H)mm |

Touch screens eliminate the need for bulky buttons and switches, which can help to save space and simplify the overall design of a control panel.The customizable interface makes the machine is easier to navigate and use.

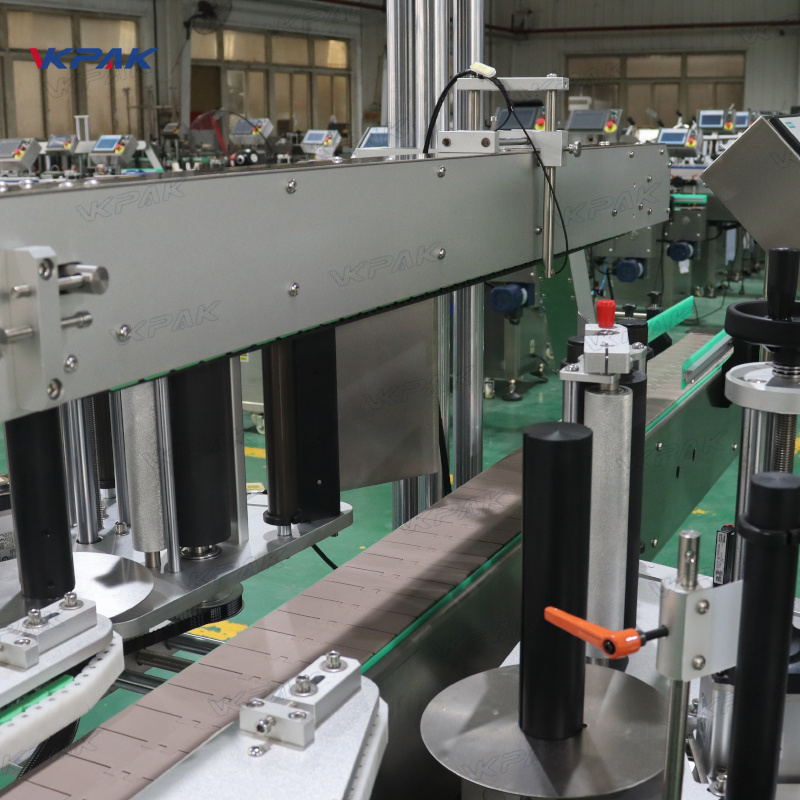

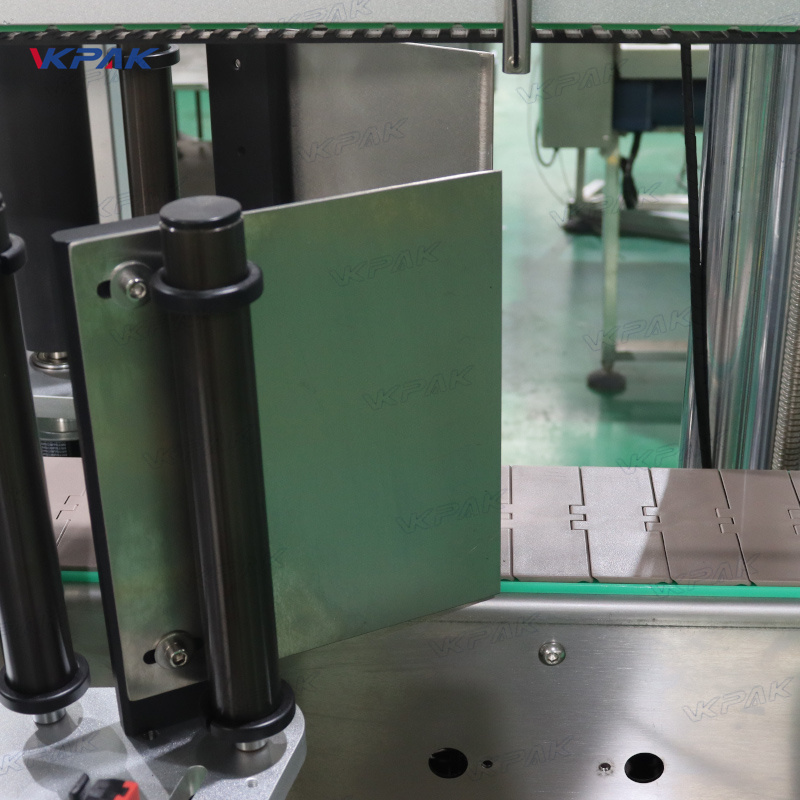

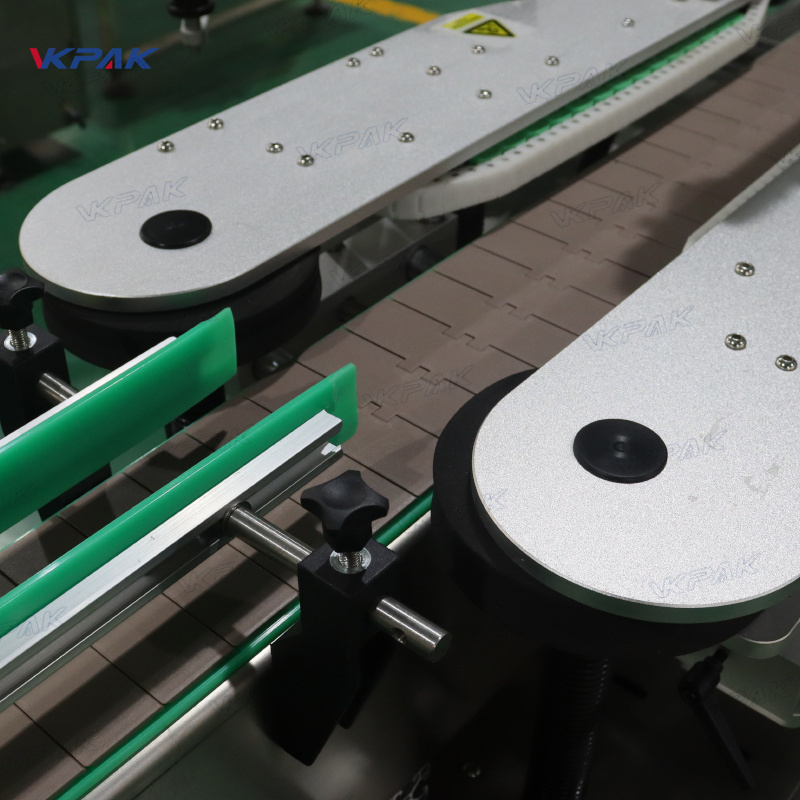

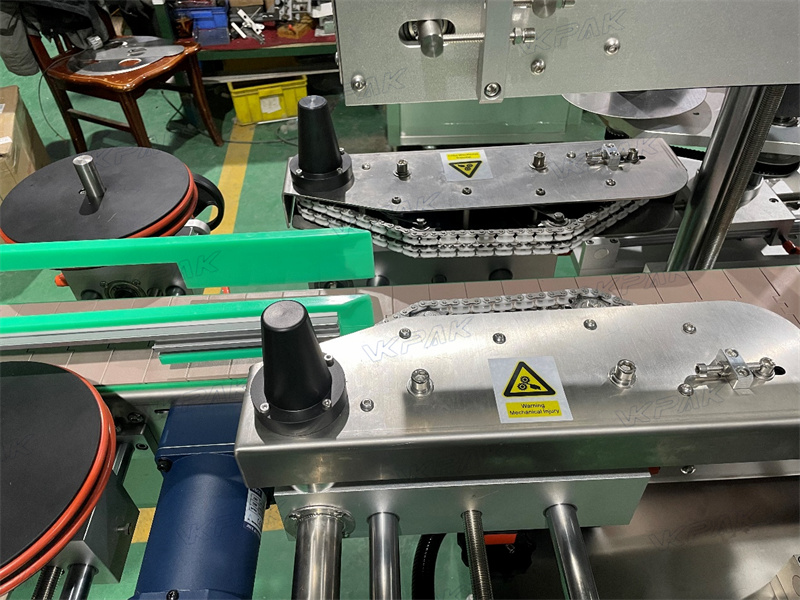

The bottle guiding structure can prevent bottles from falling down during transporting, it will be adjusted according to bottle width, this ensures labeling work can be processed stably.

The electric eye is used to detect passing by bottles and control the machine to attach labels to bottles automatically.With this , the machine can work automatically and precisely.

The label sensor can detect the gap between label and label, this will help to control the label outputting length.The sensitivity of label sensor can be adjusted according to the label material, improves labeling accuracy.

There are two brush which is designed to press labels and ensure there are no bubbles under stickers, it improves the labeling quality greatly.

VK-DSL Upgraded Version

Application

You must be logged in to post a review.

Reviews

There are no reviews yet.