VK-FBL Automatic Cosmetics Jar Glass Bottle Flat Surface Bottom Labeling Machine

$4,500.00

Tax included. Shipping calculated at checkout.

This labelling machine for applying the label from bottom on flat, round or oval containers. Versatile machine that can handle different sizes of containers and labels. The touch screen control panel makes working parameter visual, which is more convenient when debugging machines. This automatic labeling machine is designed for labeling stickers on the bottom side of bottles. It is not only good for flat surface, but also the slightly arc surface. The high accuracy labeling makes it can be widely used in food, daily chemicals, cosmetics industries.

Output Speed: 25-150 pieces/minute depends on label and bottle size

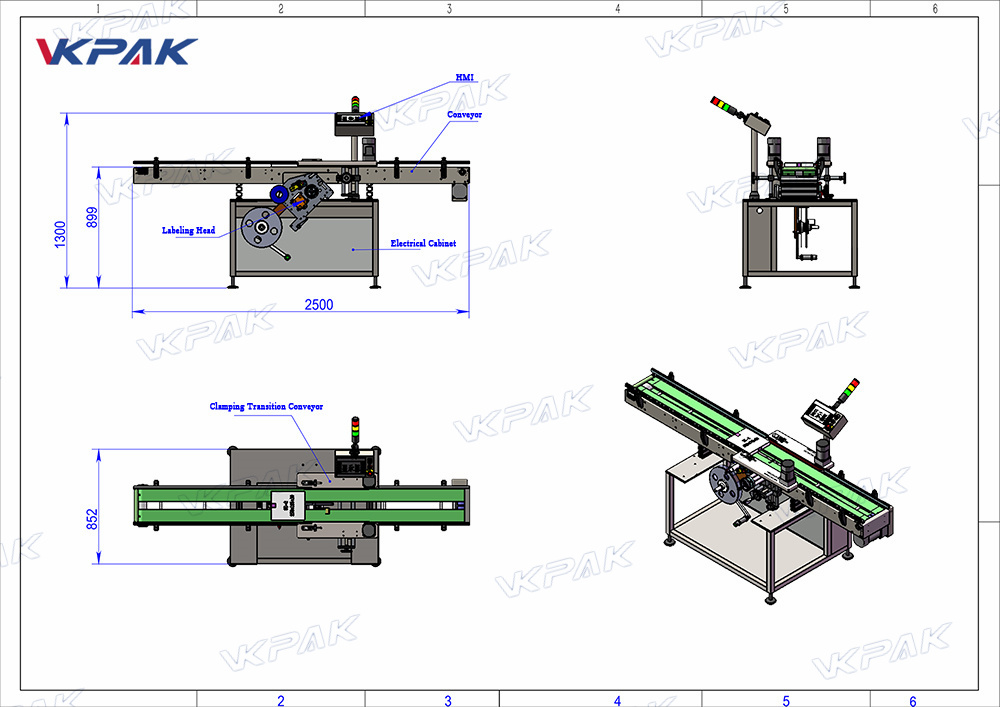

Dimension: 2000*750*1550mm

View Video Download PDF

Description

This automatic labeling machine is used for sticking labels on the bottom of bottles and boxes. It is suitable for labeling flat surface or slightly arc surface. With PLC control panel, it is easy to set working parameters. The machine can work with automatic filling machine and capping machine, improving work efficiency. If you need, please contact us.

Designed for bottom side labeling, it is good for flat/slightly arc surface.

High labeling accuracy, helps you improve labeling quality.

Technical Parameter:

| Model | VK-FBL |

| Label width | 5-180mm |

| Label length | 5-200mm |

| Labeling speed | 25-150pcs/min |

| Labeling accuracy | ±1mm |

| Power supply | 400W, 220V,50Hz/60Hz |

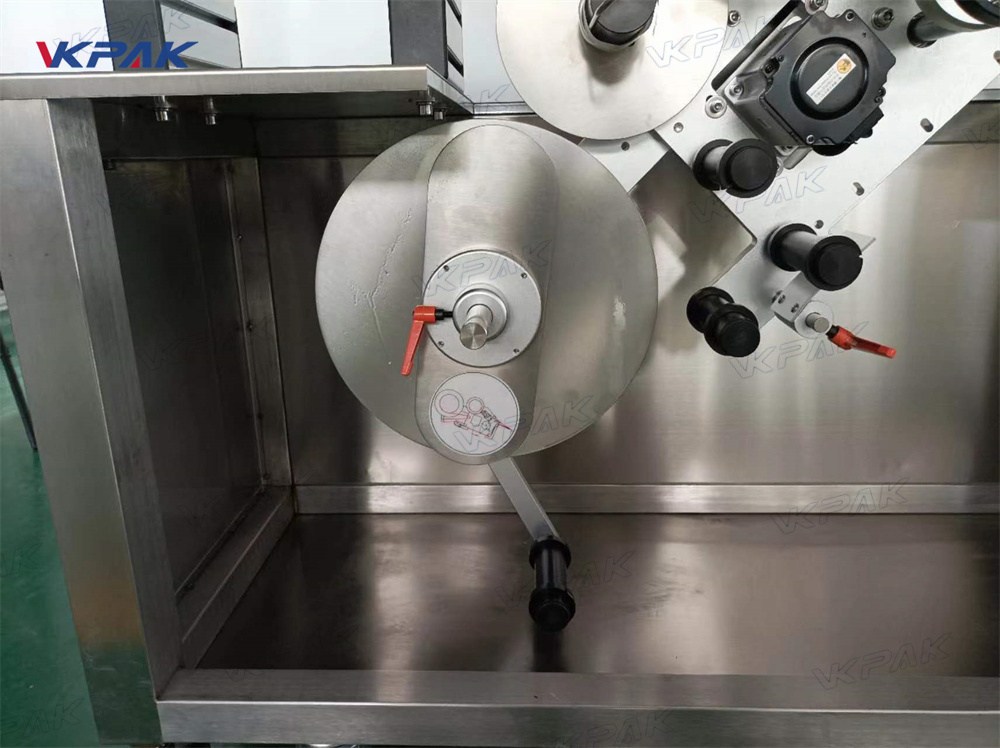

| Label reel inner diameter | 76mm |

| Label reel outer diameter | 360mm |

| Machine weight | 200kg |

| Machine size(L×W×H) | 2000×700×1600mm |

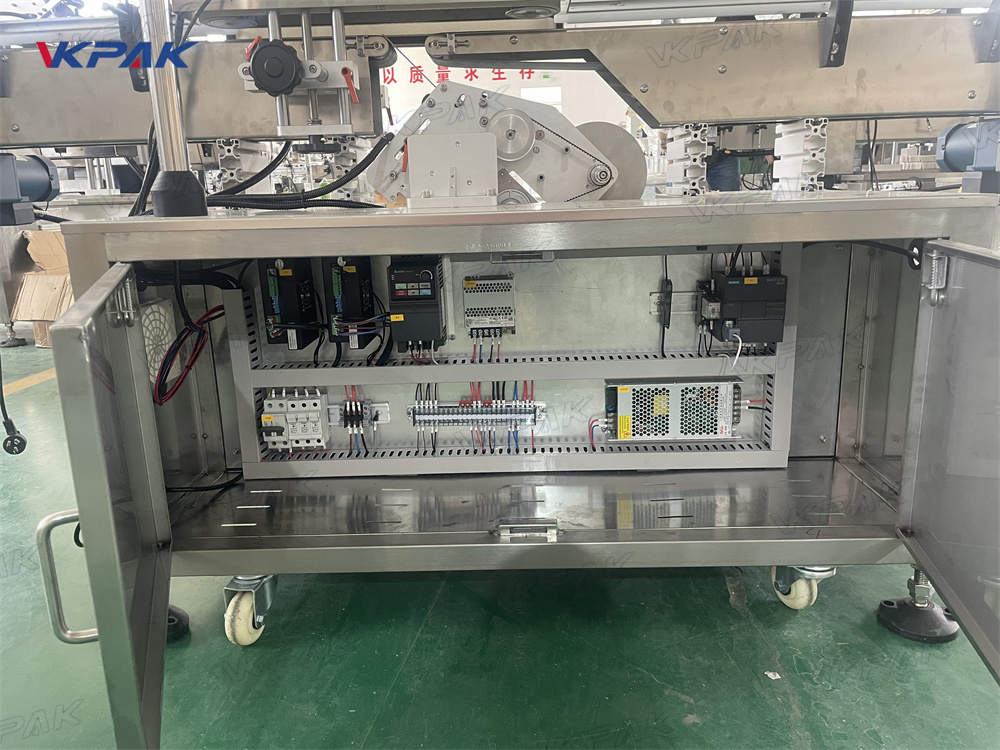

| Control system | Japanese Mitsubishi PLC |

This machine is designed with high quality touch screen control panel, which shows parameter more clear, the visual parameter can be adjusted easier as well. This is good for production management.

The machine is equipped with high quality electric eye, which is designed for detecting bottles and send signal to control the labeling work. The bottle guiding device can make bottles be in order during labeling, improve labeling quality.

High quality labeling structure, it is suitable for flat surface labeling, the label separating blade can be adjusted according to labeling products. This improves labeling effect and working efficiency.

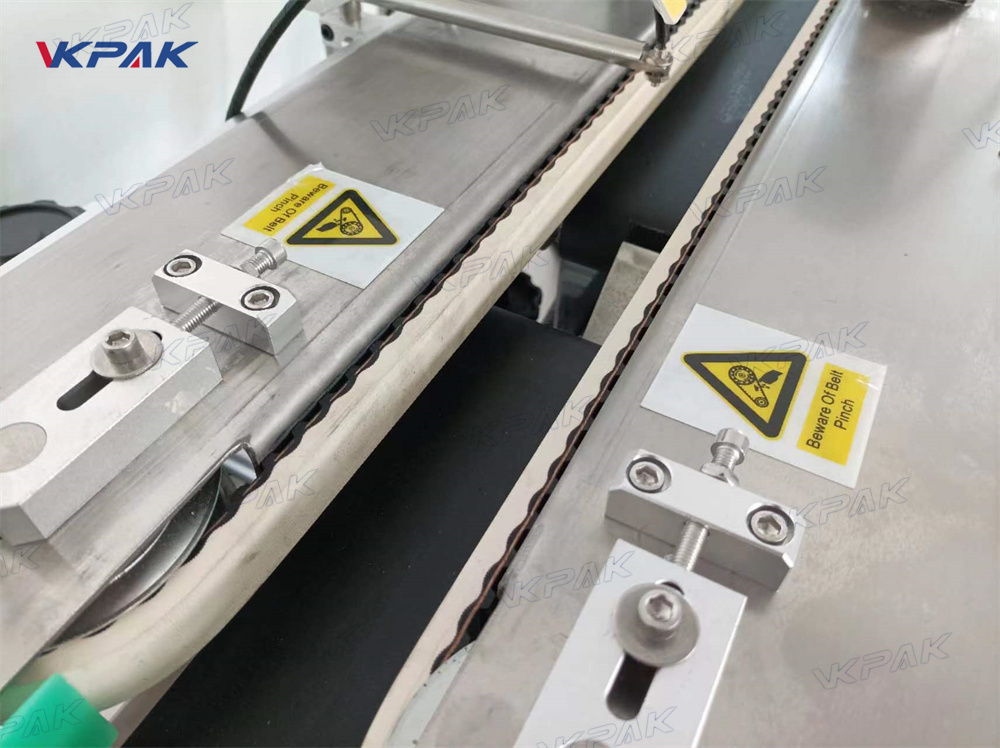

The wider conveyor belt can help to transport bottles smooth and faster, protective bar can be adjusted according to bottle diameter, prevents that bottles fall down during working.

Application

Advantages

1. Wide range of application, can meet the product width of 30mm ~ 200mm product plane labeling and self-adhesive film, replace the labeling mechanism can meet the uneven surface labeling;

2. Labeling precision, subdivision stepper motor or servo motor drive labeling, labeling precision; labeling tape winding deviation correction mechanism design, to ensure that the label traction process does not shift left and right; eccentric wheel technology applied to the traction mechanism, traction labels do not slip, to ensure that the labeling precision;

3. Sturdy and durable, the use of three rod adjustment mechanism, make full use of the stability of the triangle, the machine is solid and durable;

4. High stability, Panasonic PLC + display control touch screen + U.S. Leuze electric eye composed of advanced electronic control system to support the equipment 7 × 24 hours of operation;

5. Adjustment is simple, the design of the degree of freedom adjustable adjustment seat, the conversion between different products becomes simple and time-saving;

6. Flexible application, can be single machine production or connected to the assembly line production, production site layout is simple;

7. Intelligent control, automatic photoelectric tracking, with nothing not labeling, no labeling automatic correction and labeling automatic detection function, to prevent leakage and labeling waste;

8. Powerful function, with production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management;

You must be logged in to post a review.

Reviews

There are no reviews yet.