VK-FPL Automatic Flat Paging Top Side Hang Tag Plastic Bags Pouch Labeling Machine

$5,000.00

Tax included. Shipping calculated at checkout.

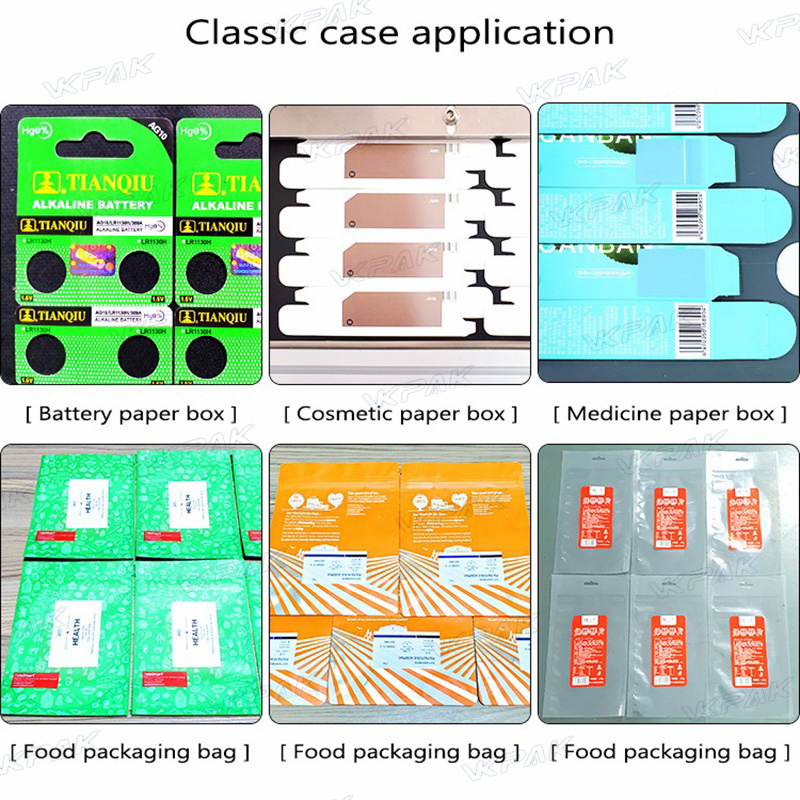

This label applicator designed for sticking labels on flat top side surface of plastic bags, stand up pouch, clothing hand tag, paper box etc. It can be selected whether to be equipped with a paging machine according to production needs. This pouch labeling machine has high working speed which can label 40-120 pieces/min, with this, you can improves your working efficiency greatly.

Output Speed: 40-120 pieces/minute depends on label and product size

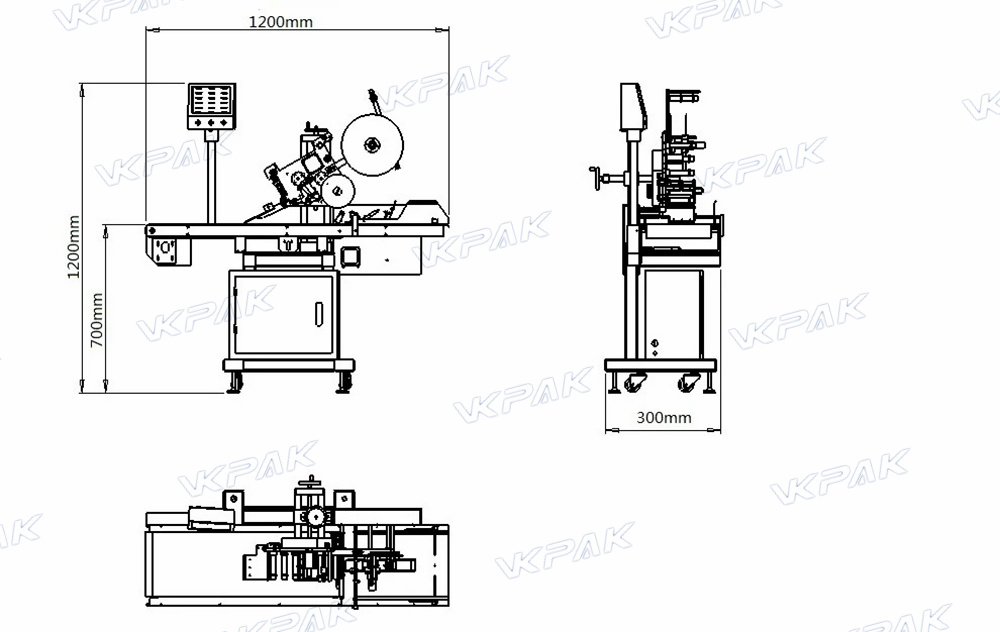

Dimension: 2800*850*1350mm

View Video Download PDF

Description

It is suitable for labeling or self-adhesive film on the upper surface of various articles, such as books, folders, boxes, cartons, etc. The replacement labeling mechanism can be applied to uneven surface labeling, which is widely used for flat labeling of large products.

Touch screen control panel will be more convenient when adjusting parameter, the labeling accuracy will be improved due to the visual working data.

This machine can separate packaging bags, paperboard automatically according to your material thickness, it is adjustable according to material thickness. The separating speed is adjustable.

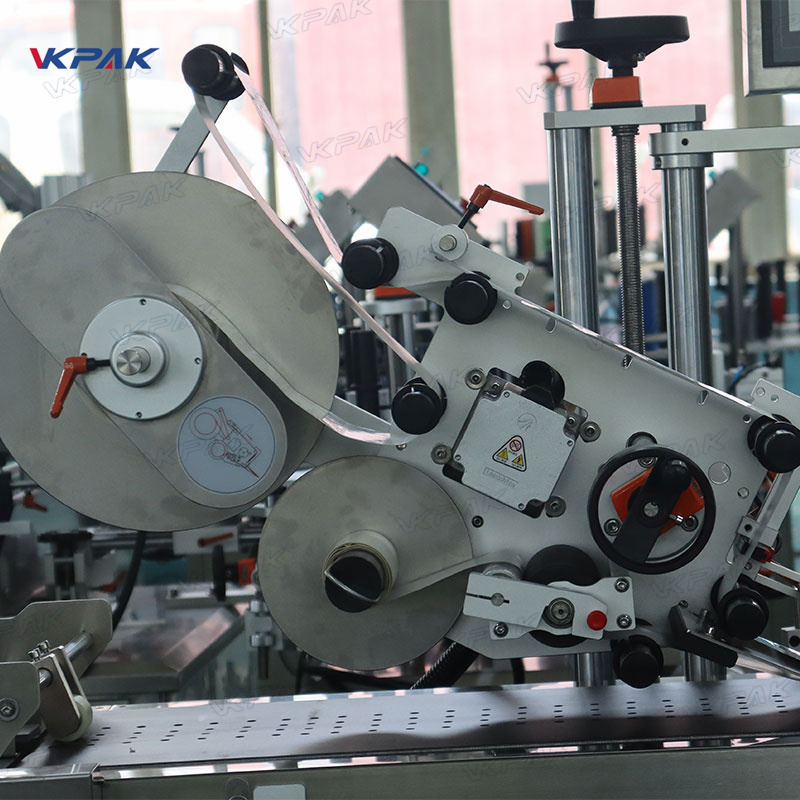

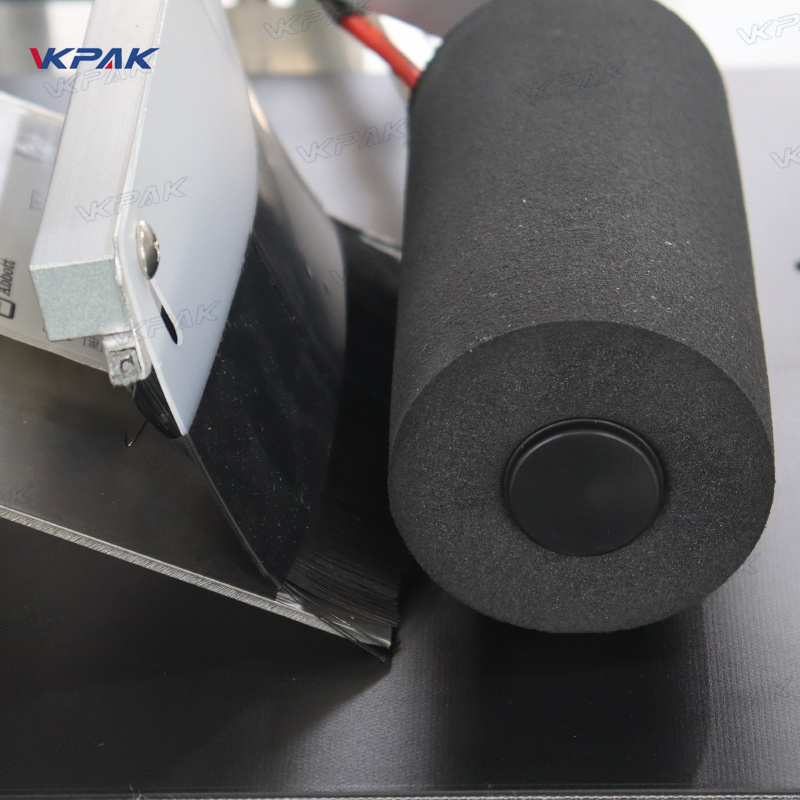

High quality labeling structure,it is suitable for flat surface labeling, work faster and can improve working efficiency.

The electric eye is designed to detect label stickers accurately, prevent from missing or wasting label sticker.

Technical Parameter:

| Machine Type | VK-FPL |

| Labeling Accuracy | ±1mm |

| Labeling Speed | 40-120 pieces/minute |

| Applicable Product Size (Length) | 40mm~280mm |

| Applicable Product Size (Width) | 40mm~200mm |

| Applicable Product Size (Height) | 0.2mm ~150mm |

| Applicable Label Size | Length: 6mm~250mm |

| Bottom paper width: 10mm ~130mm | |

| Inner Diameter Of Label Roll | 76mm |

| Label Outer Diameter | 280mm |

| Overall Size (length*width*height) | 2800*850*1350mm |

| Applicable Power Supply | 110-230V, 1phase |

| Total Weight | 300Kg |

Application

Label Sensor it can detect and output labels accurately, preventing from wasting or missing labels. Improve Labeling efficiency. The sensitivity of sensor can be adjusted as needed.

Automatic photoelectric tracking that avoids idle labeling while correcting and detecting labels automatically, so as to prevent mislabeling and label waste.

The paging machine allows you to insert a stack of your pouches or cartons so it can feed them individually past the inkjet coding printer to print your date and lot codes. The width of the feeder is adjustable based on your specific packaging dimensions.

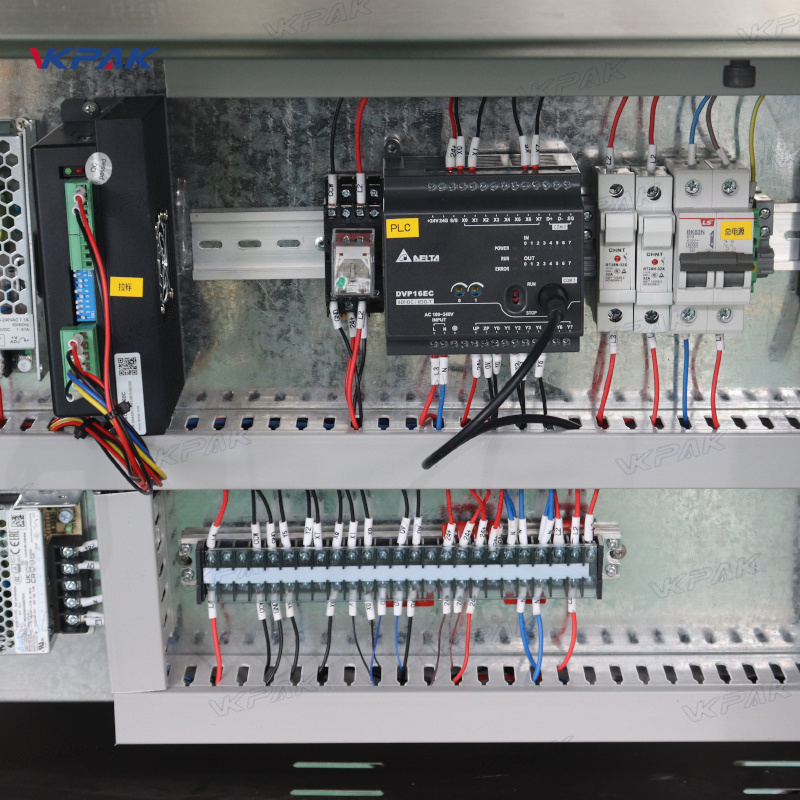

Through PLC control panel, it's easy to set parameters like labeling speed and labeling time. Easy tooperate.The language of panelcan be customized as needed. Please contact us if you need this.

Main Configuration

| Name | Brand | origin |

| Servo motor | Panasonic | Japan |

| Servo motor Drivers | Panasonic | Japan |

| Touch screen | Siemens | Germany |

| PLC | Siemens | Germany |

| Lable sensor | Leuze | Germany |

| optical fiber sensor | Omron | Japan |

| Conveyor motor | JSCC | Germany |

| speed regulator | JSCC | Germany |

You must be logged in to post a review.

Reviews

There are no reviews yet.