VK-FTL-DH Automatic Double Heads Mylar Bag Pouch Carton Box Flat Sticker Labeling Machine

$8,600.00

Tax included. Shipping calculated at checkout.

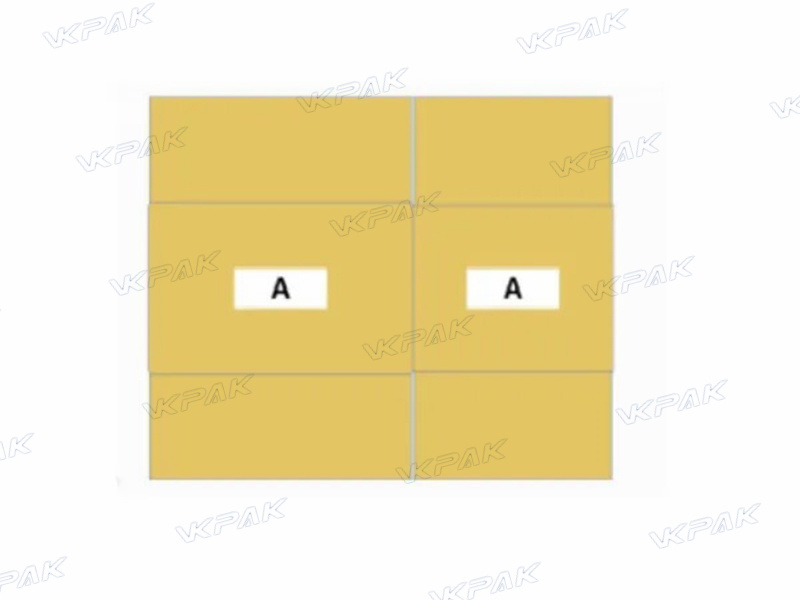

This double heads labeling machine is suitable for labeling stickers on two different positions of the flat surface. Each labeling structure can be controlled separately, helps you improve working efficiency greatly. It is widely used for mylar bags, paper cartons, electronic products.

Output Speed: 40-60 pieces/minute depends on label and product size

Dimension: (L)2600*(W)1000*(H)1500(mm)

View Video Download PDF

Description

This labeling machine is suitable for applying two labels to flat products. It is based on VK-FTL with an extended conveyor belt and an additional labeling head. It is commonly used for bags, boxes, etc.

It is one of automatic plane labeling machine, be used to label on flat surface of products, can label several stickers one time, every labeling head can work separately. If change label cover mechanism, it also can be used on uneven surface. Can select to add ribbon printer to print product’s date and system number, realize integration of labeling and printing. Can select assembly line ink-jet coder for information printing before or after labeling.

Application

Paramenters

| Model | VK-FTL-DH |

| Capacity (PCS/min) | 40-60(depend on product and label size) |

| Conveyor running side | From left to right / From right to left |

| Suitable product size | 25-250 x 20-200 x 0.2-100 mm(LxWxH) (Can customized) |

| Labeling accuracy | <±1mm |

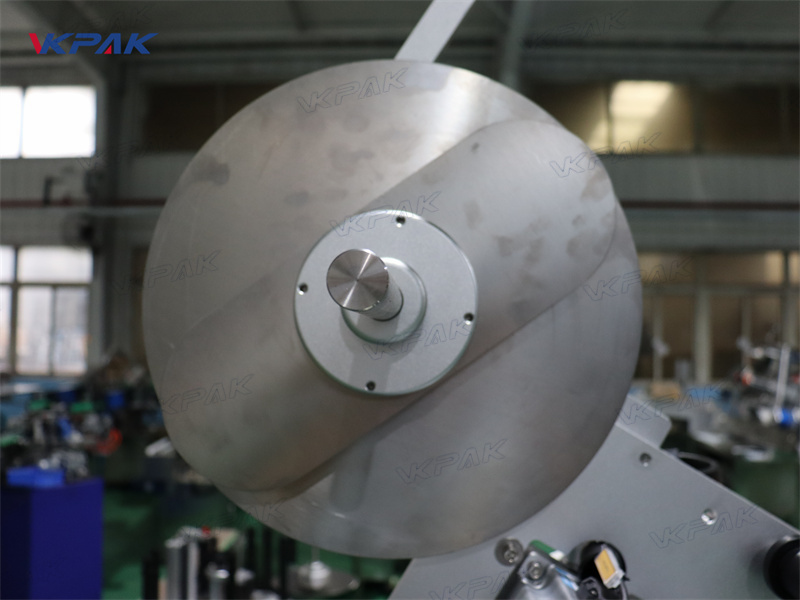

| The inner diameter of label roll | 76 mm |

| The outer diameter of label roll | 360 mm(max) |

| Suitable for label size | W:10-200 mm L: 10-150 mm |

| Power supply(In China) | AC220V 50/60HZ single phase (customized) |

| Voltage | 110V/220V/380V(can customized) |

| Weight | About 250kg |

| Machine size | About 2670x1000x1500 mm |

Details

VK-FTL-DH Touch Screen

Touch screen displays a user-friendly control interface. This touch screen allows operators to set parameters, monitor system performance, and troubleshoot issues easily. The inclusion of an emergency stop button enhances safety, making the system both efficient and secure.

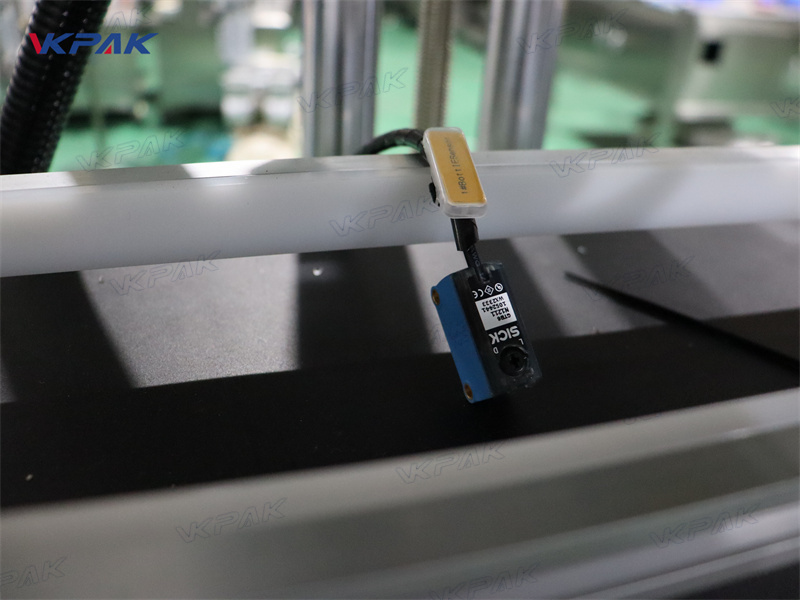

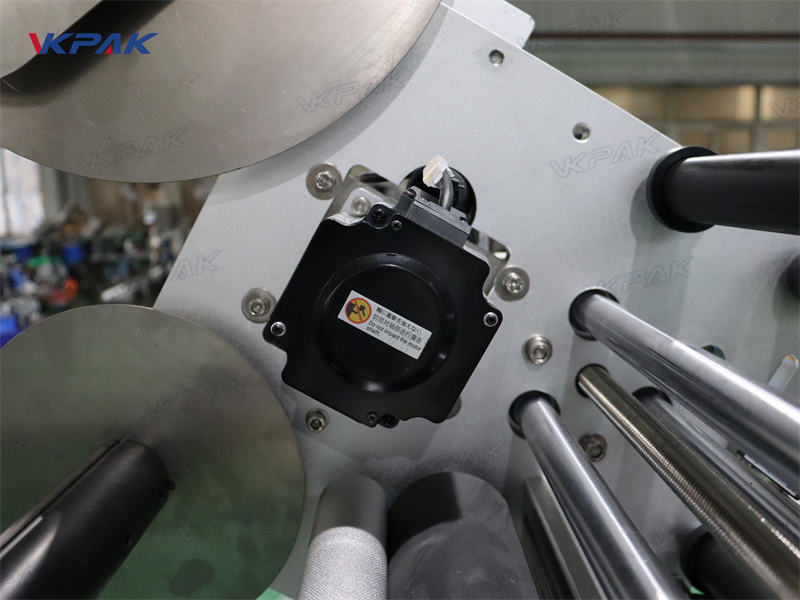

VK-FTL-DH Product Sensors

This sensor is crucial for detecting the presence and position of items on the conveyor. It ensures accurate label application and prevents mislabeling, reducing waste and improving process reliability.

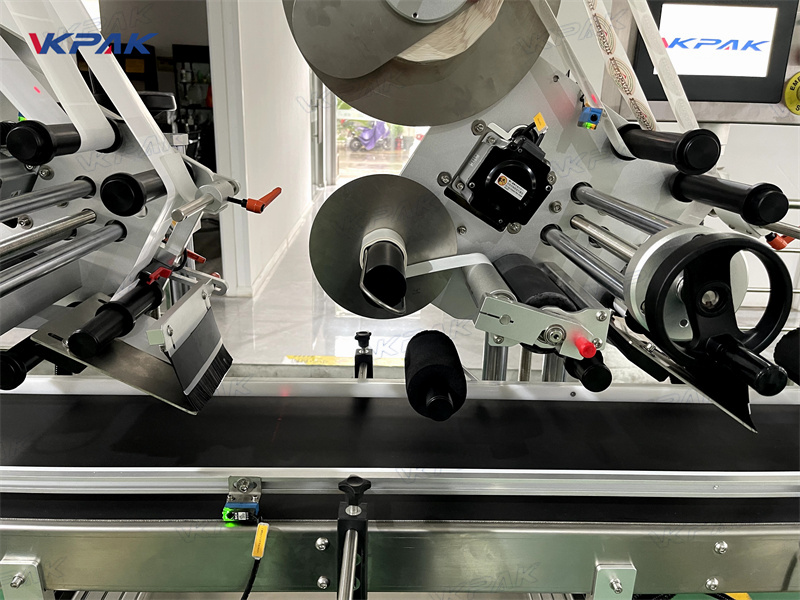

VK-FTL-DH Labeling Head

Dual-head labeling system. This component applies labels to products efficiently, ensuring precision and high throughput. Its dual-head design allows for versatility in labeling different product shapes and sizes or enables the application of two labels simultaneously, enhancing productivity.

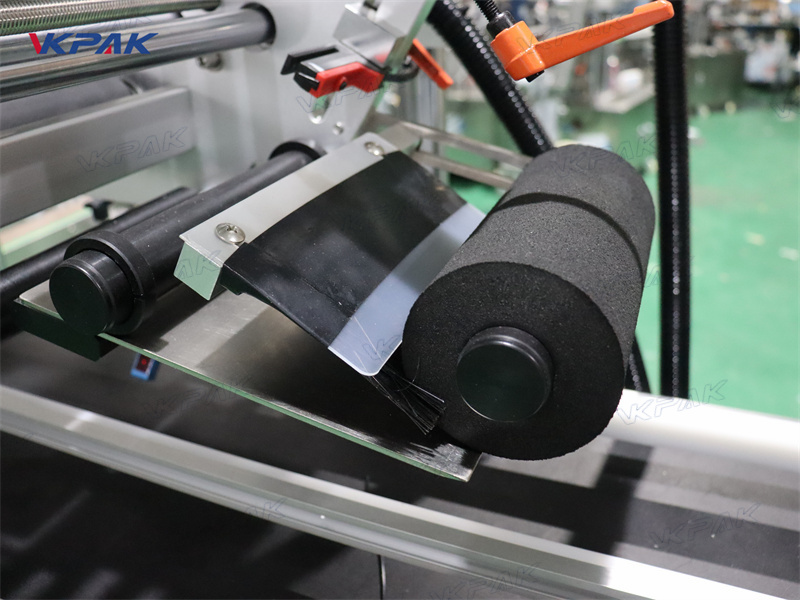

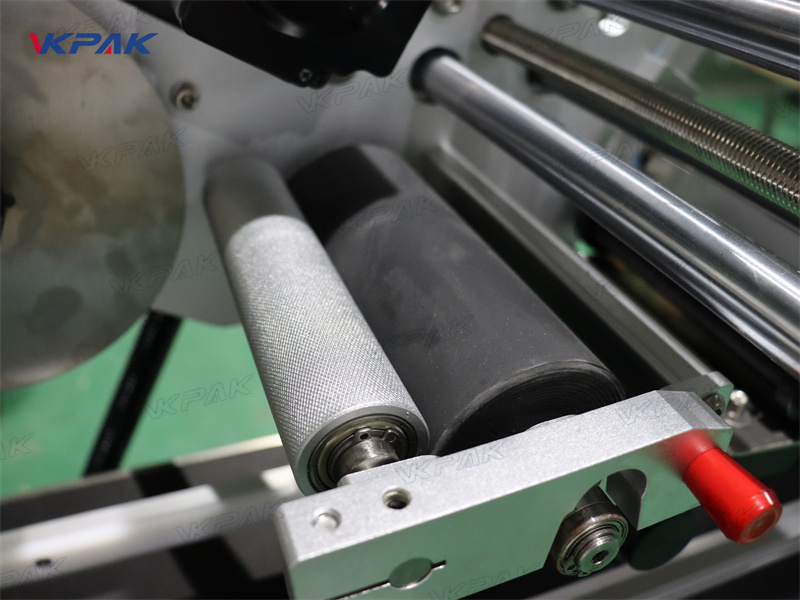

VK-FTL-DH Label Press Sponge Wheel

Sponge wheel applies even pressure to ensure labels adhere smoothly and without wrinkles. The soft material minimizes damage to labels and containers, resulting in a clean, professional finish, and is particularly useful for handling various container shapes and sizes.

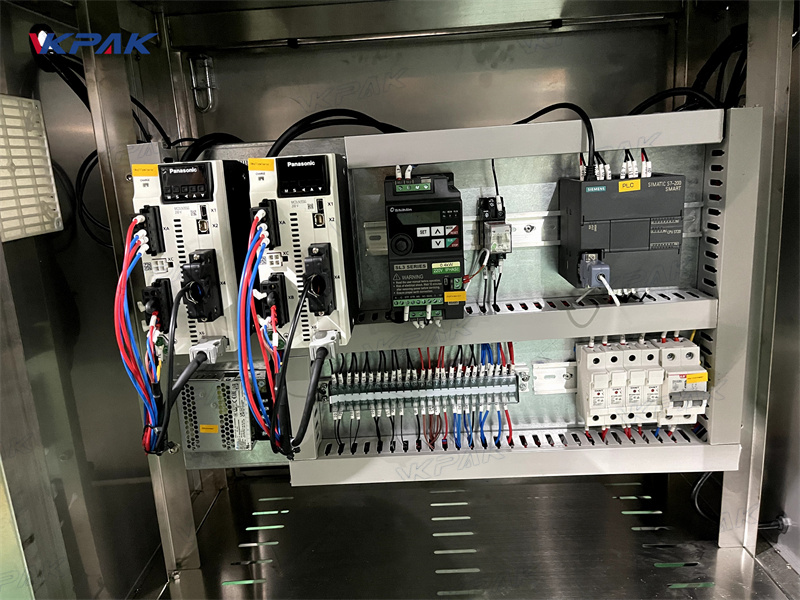

VK-FTL-DH Electrical Cabinet

This electrical cabinet houses various control elements, including PLCs (Programmable Logic Controllers) and motor controllers, which regulate machine functions. These components allow for precise control and automation, ensuring reliability, ease of maintenance, and the flexibility to adjust settings for different labeling requirements.

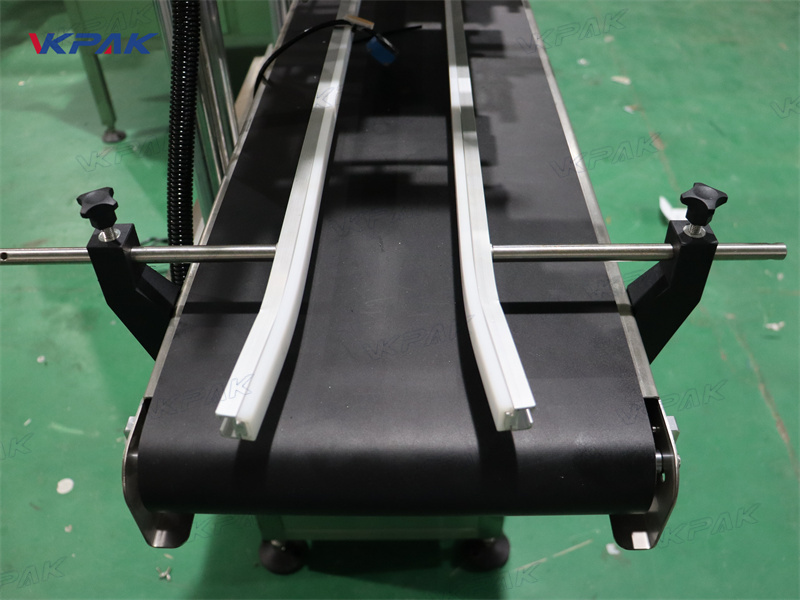

VK-FTL-DH Conveyor Belt

Conveyor belt is designed to transport products smoothly through the labeling process, ensuring accurate positioning for efficient label application. Its advantages include consistent speed, minimized manual handling, and enhanced productivity, especially in high-volume settings.

You must be logged in to post a review.

Reviews

There are no reviews yet.