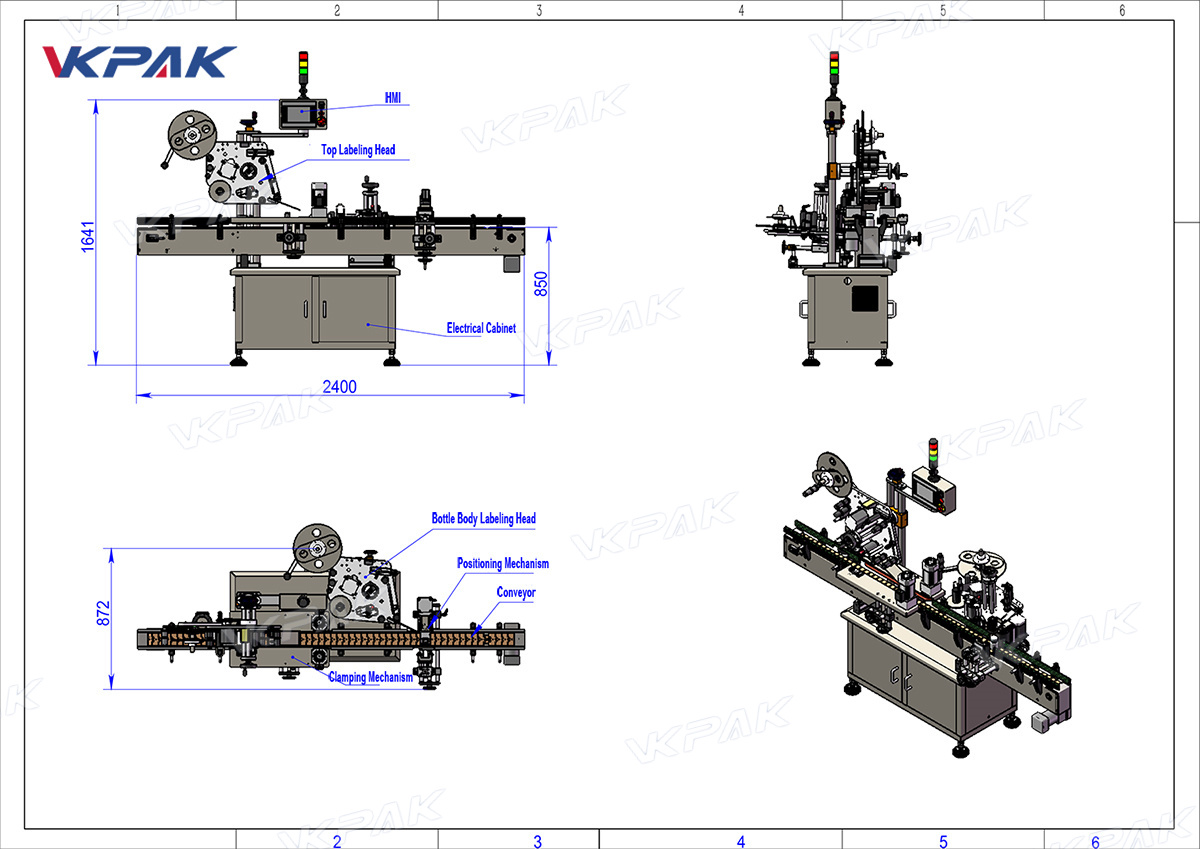

VK-FTL-RP Automatic Cosmetic Jar Flat Top Lid Cap And Body Food Bottle Labeling Machine

$6,800.00

Tax included. Shipping calculated at checkout.

This automatic labeling machine is with two labeling heads, one for flat surface, one for round bottles. It is normally used for labeling bottle caps and bottles at the same time. This machine is widely used in food, daily chemicals, cosmetics industries.

Output Speed: 25-45 pieces/minute depends on label and product size

Dimension: (L)2500*(W)1100*(H)1600(mm)

View Video Download PDF

Description

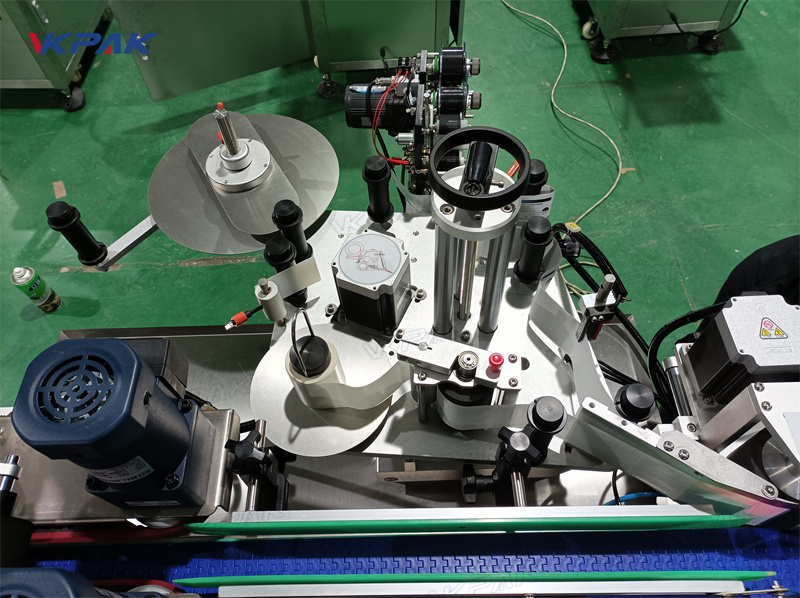

This labeling machine is a combination of VK-FTL and VK-RPL, which can label the top and the body of the bottle at the same time.

It has two labeling heads, one for flat surface, one for curved surface. It is normally used for labeling bottle caps and bottles at the same time. This bottle labeling applicator is widely used in food, daily chemicals, cosmetics industries.

Designed for labeling sticker on bottle caps & body.

It is suitable for bottle body single side & double side labeling.

Application

Drawing

Paramenters

| Model | VK-FTL-RP |

| Labeling Speed(pcs/min) | 25-45(relate to product and label size) |

| Labeling Accuracy(mm) | ±1.0mm |

| Suitable Label Size(mm) | (L)10-300mm (H)10-150mm |

| Suitable Product Size | Diameter: 25-100mm, H:30-180mm |

| Roll Inside Diameter(mm) | Φ76mm |

| Roll Outside Diameter(mm) | Φ320mm |

| Machine Size(mm) | (L)2500*(W)1100*(H)1600(mm) |

| Power Supply | AC220V 50Hz/60Hz (Customizable) |

| Operation Direction | Left To Right Or Right To Left |

| Net Weight | About 350Kg |

| Label Material | Self-Adhesive Sticker, Opaque Or Transparent Label |

Design with touch screen control panel, it is more convenient to adjust machine parameter. We can customize the control panel in different kinds of languages, if you need this please contact us.

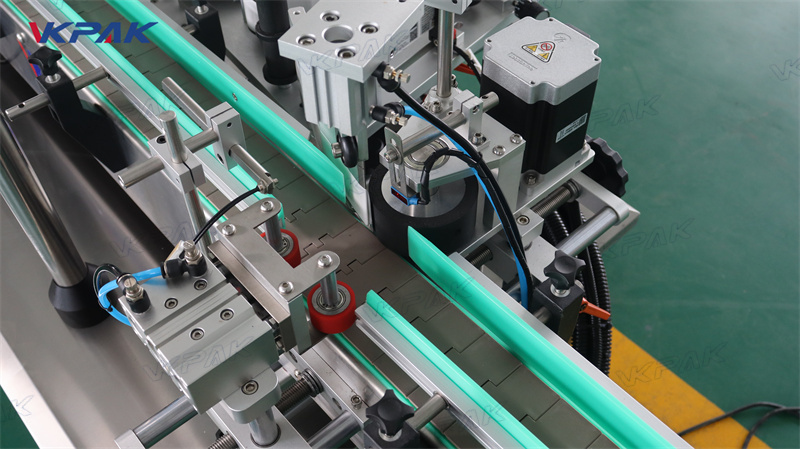

The bottle separating wheel is used to separate bottles during working, makes the production can be in order, reduce production error and improve working efficiency.

With two kinds of labeling head, this machine can be used to labeling sticker on flat surface and wrapping around bottles. The electric eyes can be used to detecting objects, improves labeling accuracy.

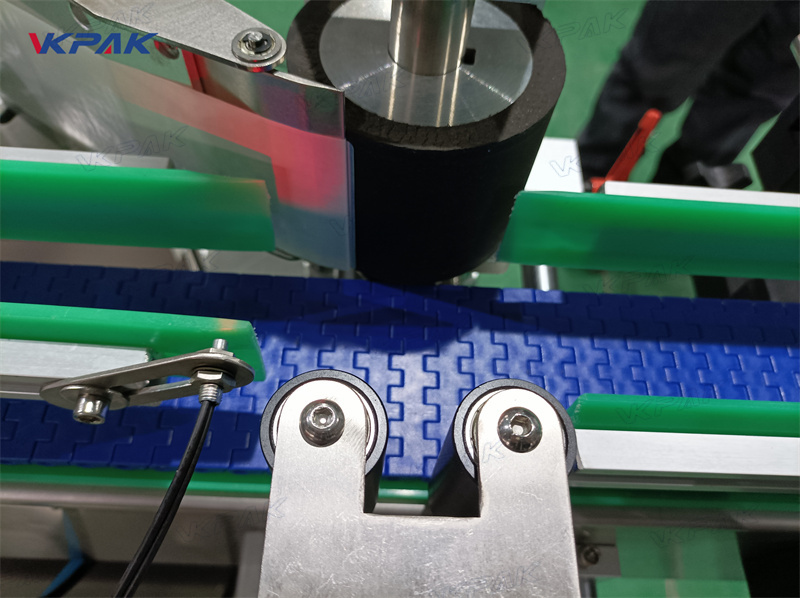

The chain conveyor belt is with larger loading capacity, it can help to transport bottles. The guard railing can be adjusted according to bottles diameter, makes sure the bottle can be conveyed smoothly.

Details

VK-FTL-RP Touch Screen

The touch screen control panel (by Siemens). It serves as the interface for operating and configuring the labeling machine. Its advantages include intuitive operation, customizable settings, and easy monitoring of the machine’s performance, leading to reduced downtime and user-friendly control.

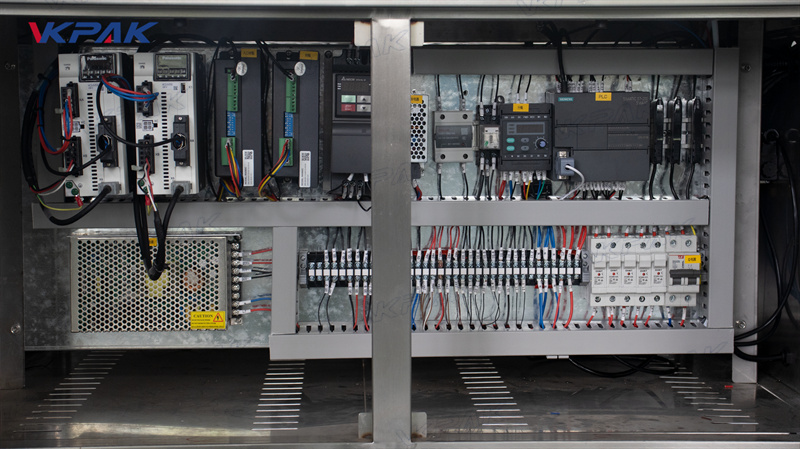

VK-FTL-RP Electrical Cabinet

This houses the electrical and control systems, including PLCs, drivers, and power supplies, ensuring efficient and synchronized operation of the labeling machine. Its organized wiring and robust structure provide easy maintenance, reliability, and consistent performance.

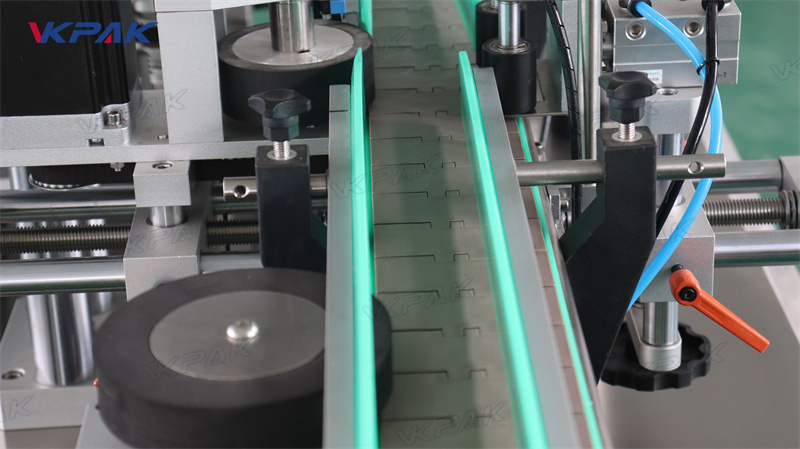

VK-FTL-RP Conveyor Belt

The conveyor belt ensures the smooth and continuous movement of products through the labeling process. The adjustable side guides enhance flexibility for handling products of varying sizes and shapes, ensuring precise label application and preventing misalignment.

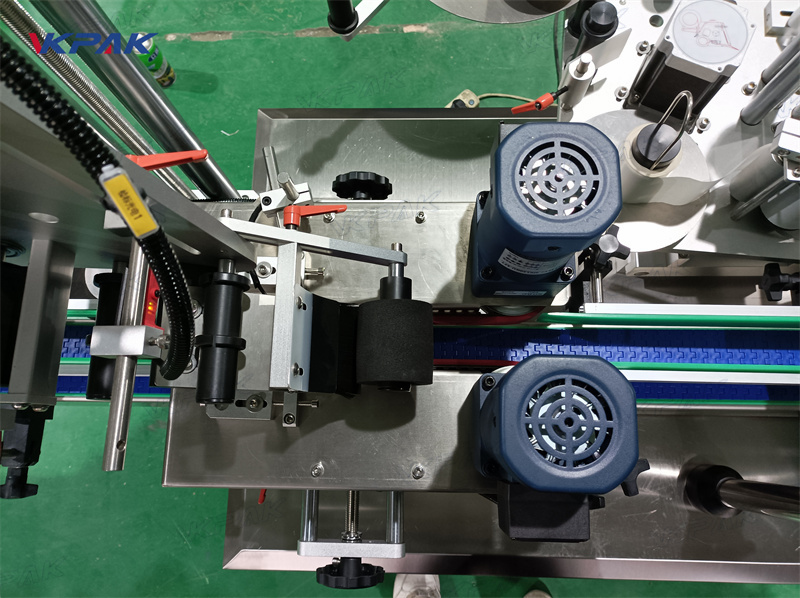

VK-FTL-RP Three-Roller Clamp

The three-roller clamp system, which firmly holds and rotates round bottles during labeling. This system’s advantage lies in its ability to enhance labeling precision by maintaining bottle stability and synchronization, even at higher speeds, while accommodating different bottle sizes.

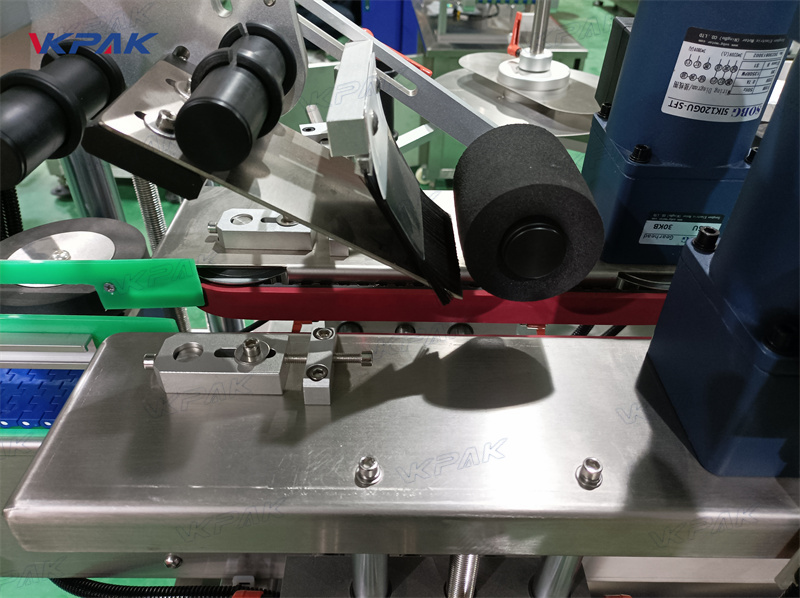

VK-FTL-RP Flat Labeling Head

Flat labeling head is responsible for accurately applying labels to flat surfaces. Its ergonomic design and adjustable mechanisms make it suitable for a wide range of product sizes, ensuring high-speed operation with precision, minimizing waste, and reducing downtime.

VK-FTL-RP Round Bottle Positioning Labeling Head

The labeling head, which is the core component used to apply labels to products. It ensures precise label placement on round bottles by accurately dispensing and adhering the labels during operation. Its advantage lies in its reliability for high-speed labeling, enhancing production efficiency while maintaining consistency.

You must be logged in to post a review.

Reviews

There are no reviews yet.