VK-HRL-D Automatic Horizontal Round Product Labeling Machine With Feeding Hopper

$4,800.00

Tax included. Shipping calculated at checkout.

This labeling machine is suitable for labeling various long cylindrical products.

Designed for non-standing cylindrical containers or products that are not vertically stable (round bottom or top-heavy) including ampoule, vials, crayons, tube, lip balm containers, small batteries, etc.

The difference between this labeling machine and VK-HRL-M is that it is equipped with a feed hopper customized according to the product to improve feeding efficiency and speed up labeling.

Output Speed: 60-200 pieces/minute depends on label and product size

Dimension: (L)1900*(W)1100*(H)1300(mm)

View Video Download PDF

Description

This labeling machine is suitable for labeling various long cylindrical products.

It is complied with GMP standard that provides easy maintenance and for a long durable life.

High speed, adopt roller transmission conveyor, products be putted on the right place automatically, labeling steadily, speed can catch to 200pcs/min. Saving large labor and material.

High quality labeling, correct label belt be in right position, label cover label accurate, rolling and nobbing press label result in an even, no scrape, no air bubble on ever product. Improve packing quality.

High stability, support equipment working at 7*24hours.

Intelligent control, Automatic photoelectric tracing, no product, no labeling.

Automatic correcting, automatic testing, can avoid leaking and wasting.

Application

Applicable labels: self-adhesive label, self-adhesive film, electronic supervision code, bar code, etc.

Applicable products: round container, small cylindrical container

Applicable industries: pharmaceutical, cosmetics, electronics, hardware, plastic, etc.

Paramenters

| Model | VK-HRL-D |

| Labeling Speed(pcs/min) | 60-200(relate to product and label size) |

| Labeling Accuracy(mm) | ±1.0mm |

| Suitable Label Size(mm) | (L)15-80mm (H)10-80mm |

| Suitable Product Size | Diameter: 10-100mm, H:30-180mm |

| Roll Inside Diameter(mm) | Φ76mm |

| Rollouter Diameter(mm) | Φ320mm |

| Machine Size(mm) | (L)1900*(W)1100*(H)1300(mm) |

| Power Supply | AC220V50Hz/60Hz/980W |

| Operation Direction | Left To Right Or Right To Left |

| Net Weight | About 250Kg |

| Label Material | Self-Adhesive Sticker, Opaque Or Transparent Label |

Details

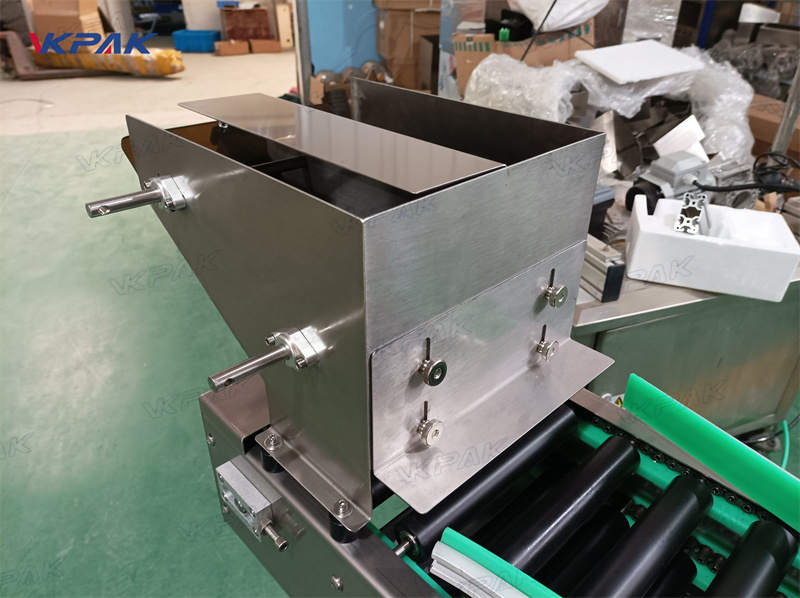

VK-HRL-D Feeding Hopper

The hopper is constructed from stainless steel, indicating durability and suitability for industrial use. This part is designed to hold and guide items onto the conveyor belt in a controlled manner, ensuring smooth and orderly feeding for the labeling process. The metal structure includes adjustable handles and knobs, allowing operators to fine-tune the setup for different product sizes.

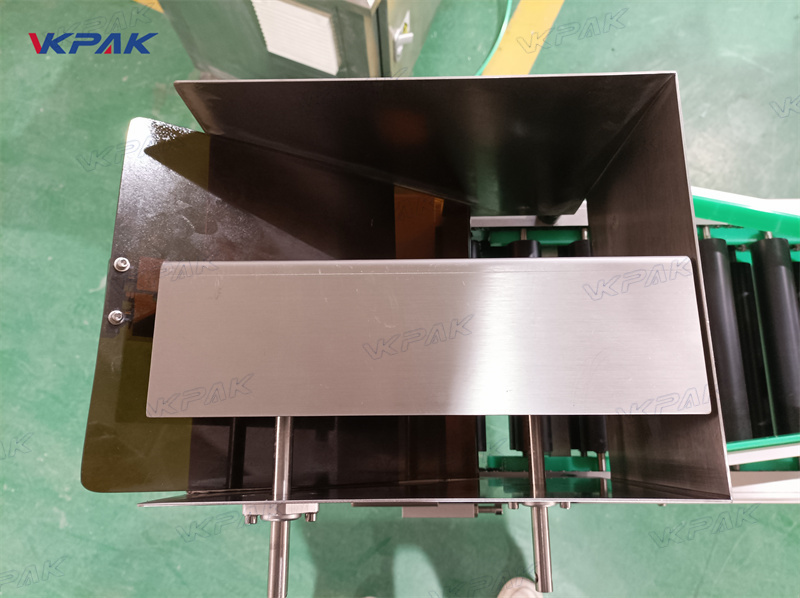

VK-HRL-D Feeding Hopper Top View

The hopper’s design includes a spacious, rectangular opening that allows products to be loaded easily and aligned onto the conveyor belt below. The stainless steel construction emphasizes both durability and hygienic qualities, ideal for various industrial applications. This angle highlights the internal structure of the hopper, which is streamlined to guide items efficiently into a single file, minimizing jams and ensuring consistent flow.

VK-HRL-D Labeling-Head

The VK-HRL-D Labeling Head is an efficient, precision-driven labeling machine designed for automated, high-volume packaging. It features an advanced applicator and user-friendly controls, ensuring accurate label placement on various products, boosting productivity and reducing labor needs.

VK-HRL-D Roller Conveyor

The VK-HRL-D Roller Conveyor is a durable, high-efficiency component designed to transport products smoothly through the labeling process. Its sturdy rollers and guiding rails ensure stable movement, minimizing the risk of product misalignment. Ideal for high-speed production lines, this conveyor system enhances workflow efficiency while seamlessly integrating with labeling equipment for consistent, precise labeling results.

VK-HRL-D Touch Screen

The VK-HRL-D Touch Screen, featuring Siemens’ Smart Line interface, provides intuitive, centralized control for the labeling system. With its clear touchscreen display, operators can easily adjust settings, monitor system status, and troubleshoot in real-time. The panel also includes an emergency stop button for enhanced safety, ensuring rapid response in case of any issues. This control interface streamlines operations, boosting efficiency and reducing downtime on the production line.

VK-HRL-D Label Press Belt

It plays a critical role in ensuring that labels are accurately affixed to products by applying consistent pressure or guiding them through the labeling process. The advantage of this type of design is that it helps maintain label alignment and prevents wrinkling or misplacement, leading to a high-quality, professional appearance on labeled products.

You must be logged in to post a review.

Reviews

There are no reviews yet.