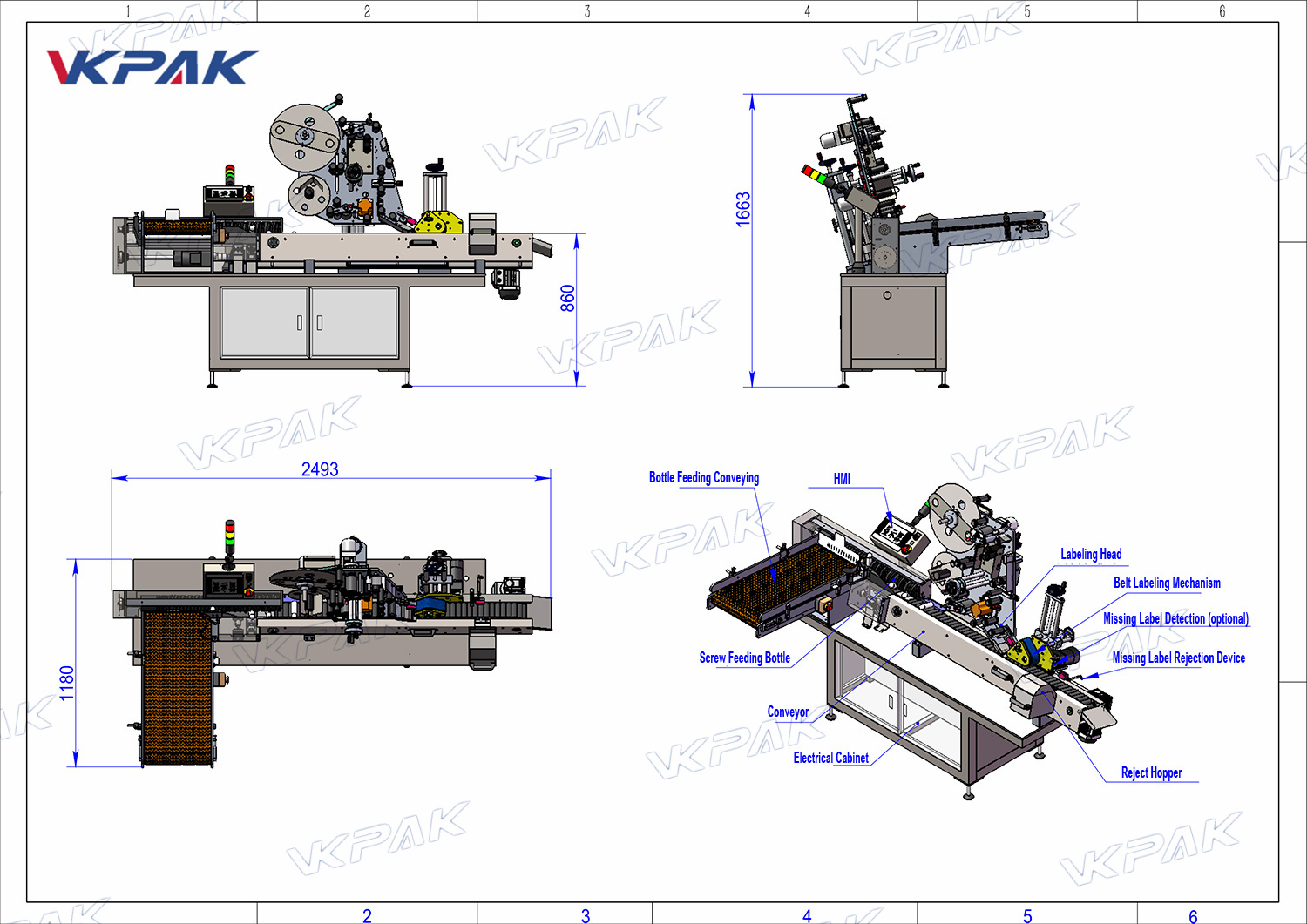

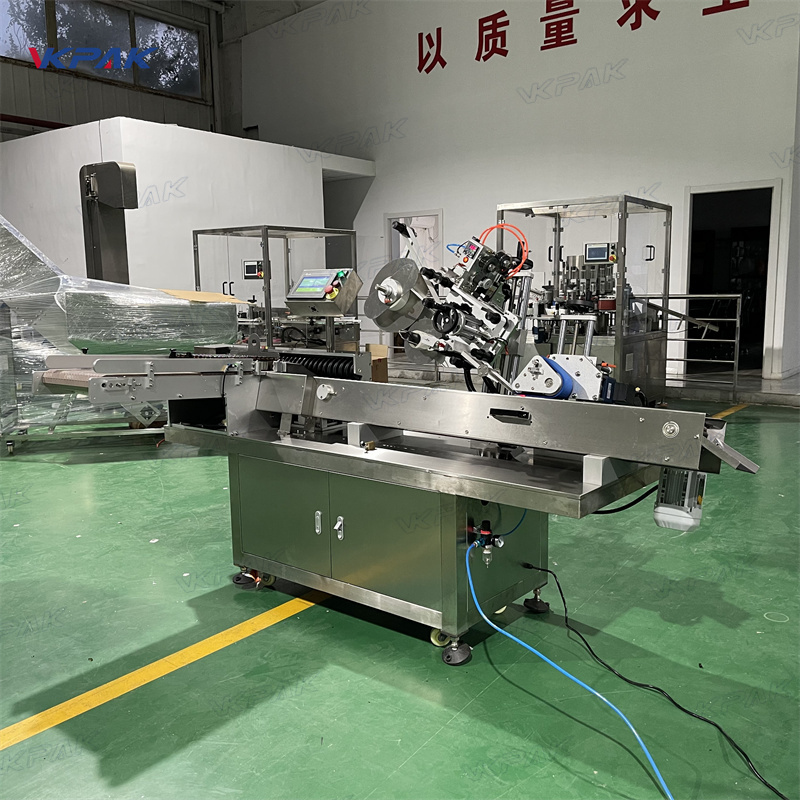

VK-HRL-H High Speed Horizontal Ampoule Small Round Bottle Vial Labeling Machine

$11,000.00

Tax included. Shipping calculated at checkout.

The labeling system offers extra high speed operation, proven stability, and flexible material change. Applicable to vials, ampoules and other thin and narrow bottles.

It is applicable for the labeling of the objects with small diameters and unable to stand up easily, such as oral liquid bottles, ampoule bottles, needle tube bottles, batteries, hams, sausages, test tubes, pens and so on.

Output Speed: 400-600 pieces/minute depends on label and product size

Dimension: (L)2600*(W)1400*(H)1700(mm)

View Video Download PDF

Description

The equipment is suitable for labeling the circumference or semi-circumference of various standing unstable cylindrical objects.

This labeler machine can complete the labels of oral liquid bottles, water needle ampoules or other kinds of slender bottles. Touch screen operation, PLC full control; according to different labels, intelligent retrieval, determine the parameters; another reference hot print head synchronization print batch number, no bottle no sign, no print, automatic shutdown, display alarm. The machine is strong anti-interference, high degree of humanity, stable and reliable performance.

It can print batch number and production date at the same time, realize the integration of labeling and coding, reduce packing process and improve production efficiency.

Application

Paramenters

| Model | VK-HRL-H |

| Labeling Speed(pcs/min) | 400-600(relate to product and label size) |

| Labeling Accuracy(mm) | ±1.0mm |

| Suitable Label Size(mm) | (L)15-80mm (H)10-80mm |

| Suitable Product Size | Diameter: 10-24mm, H:30-110mm |

| Roll Inside Diameter(mm) | Φ76mm |

| Rollouter Diameter(mm) | Φ320mm |

| Machine Size(mm) | (L)2600*(W)1400*(H)1700(mm) |

| Power Supply | AC220V50Hz/60Hz/980W |

| Operation Direction | Left To Right Or Right To Left |

| Net Weight | About 250Kg |

| Label Material | Self-Adhesive Sticker, Opaque Or Transparent Label |

Details

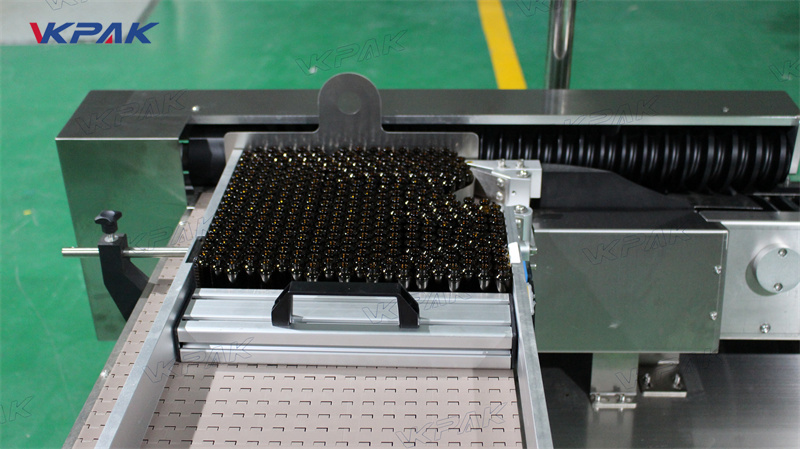

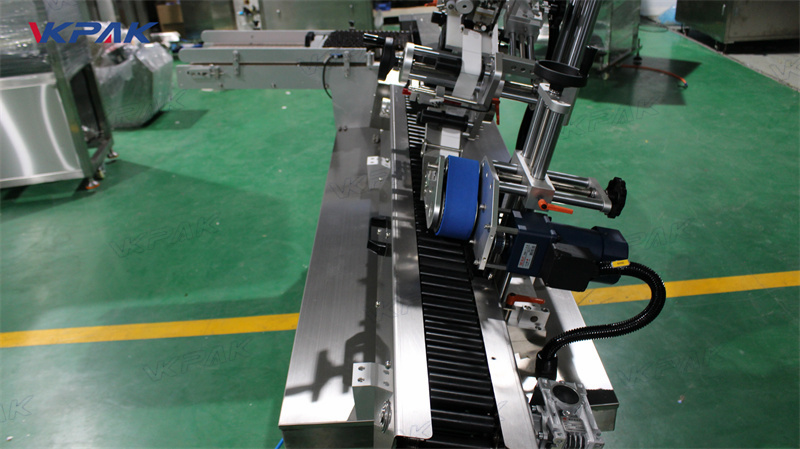

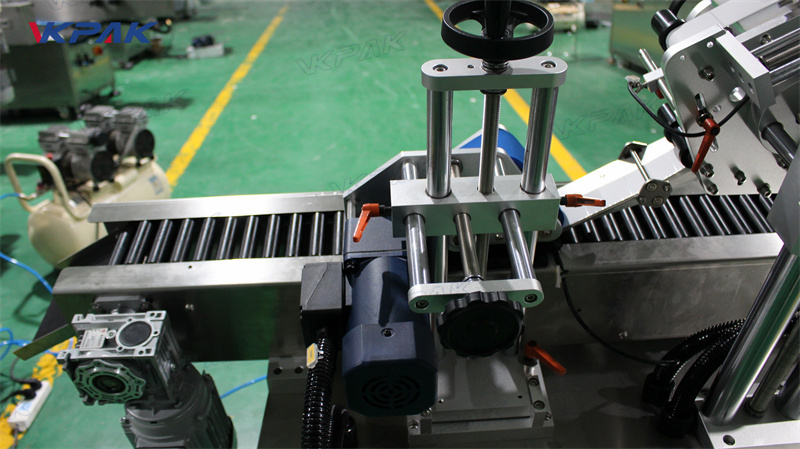

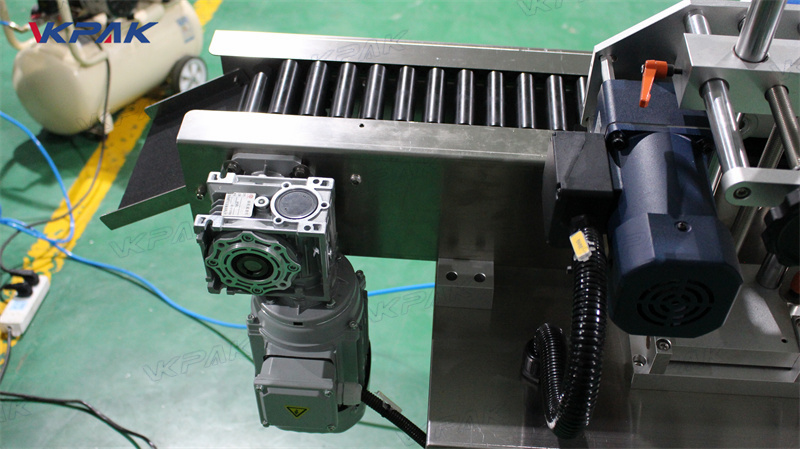

VK-HRL-H Bottle Feeding Station

The Bottle Feeding Station serves as the entry point where bottles are organized and fed onto the labeling line. By keeping bottles securely positioned, it supports an orderly transition into the labeling process, improving speed and minimizing misalignment or mishandling of products.

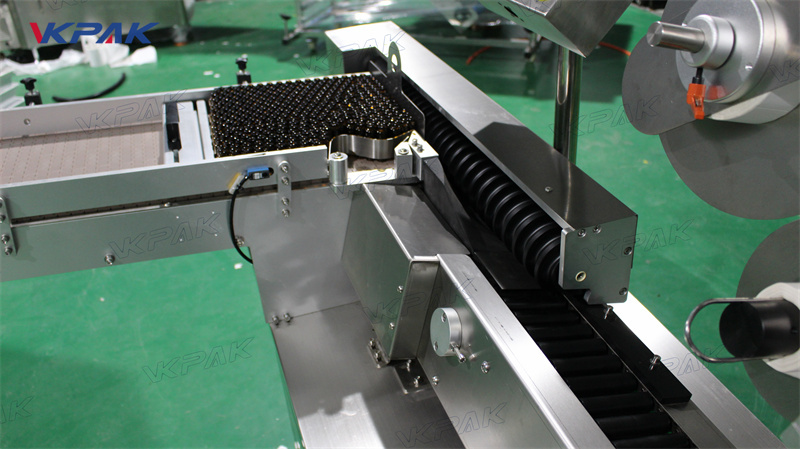

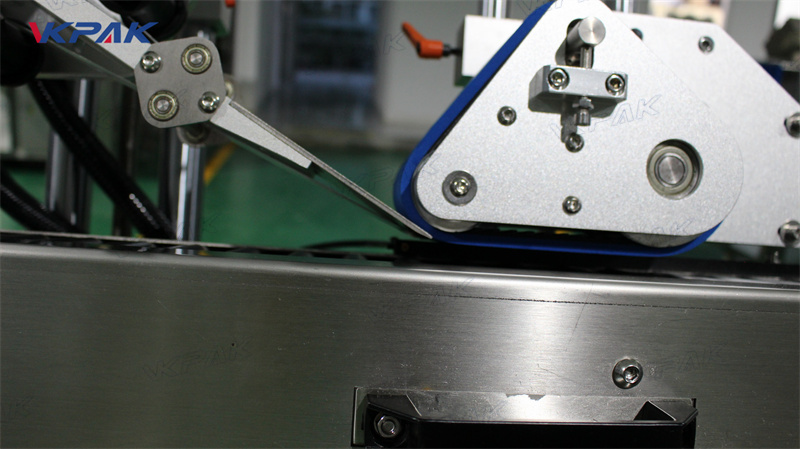

VK-HRL-H Bottle Feeding Screw

The Bottle Feeding Screw is designed to align and control the flow of bottles as they move along the conveyor, ensuring smooth and consistent spacing for precise labeling. This mechanism is essential for maintaining a steady production rate and reducing the risk of jams, leading to greater efficiency and accuracy.

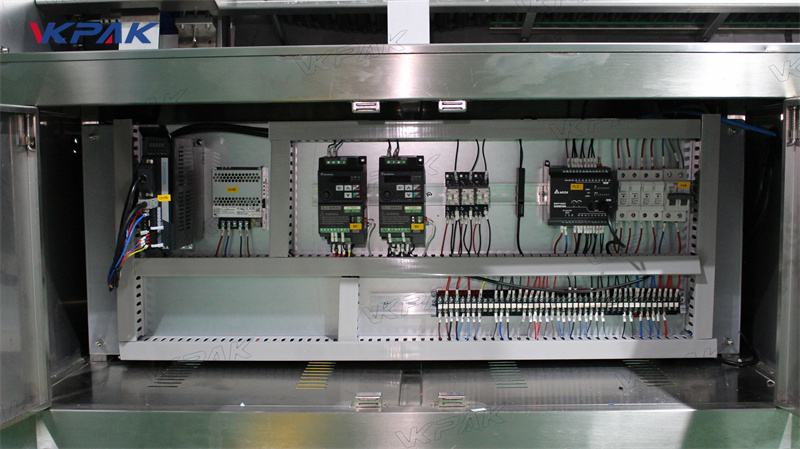

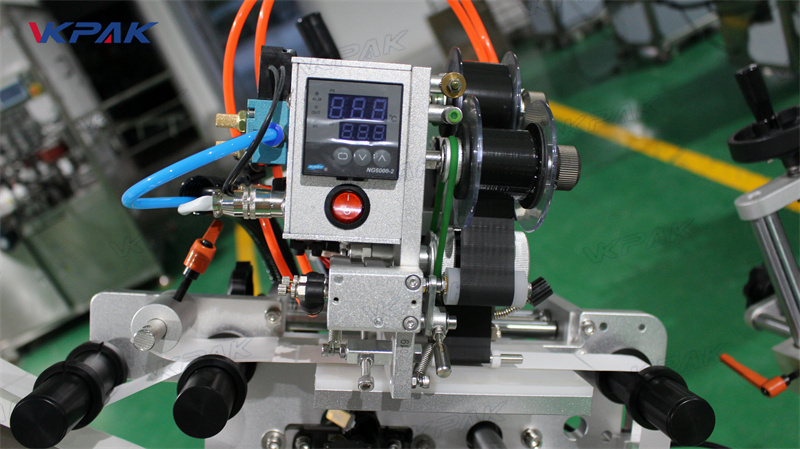

VK-HRL-H Electric Cabinet

The Electric Cabinet houses the control systems that power and manage the labeling machine’s operations. This centralized setup allows for easy monitoring and adjustment of machine parameters, enhancing operational reliability and ensuring a consistent labeling process by safeguarding electrical components from environmental factors.

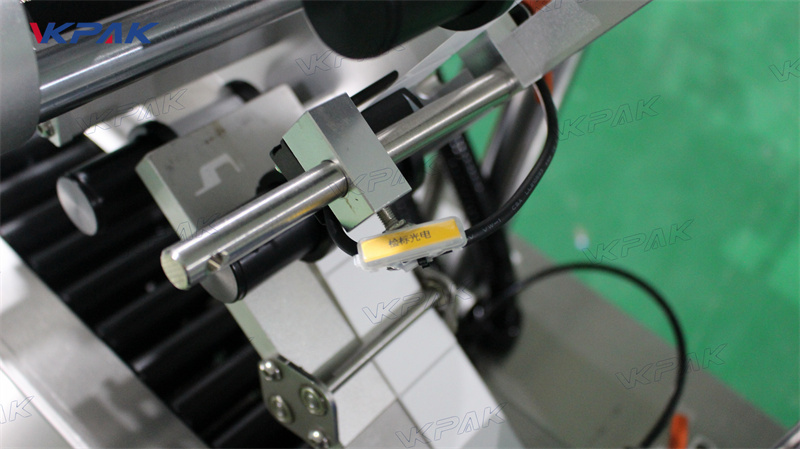

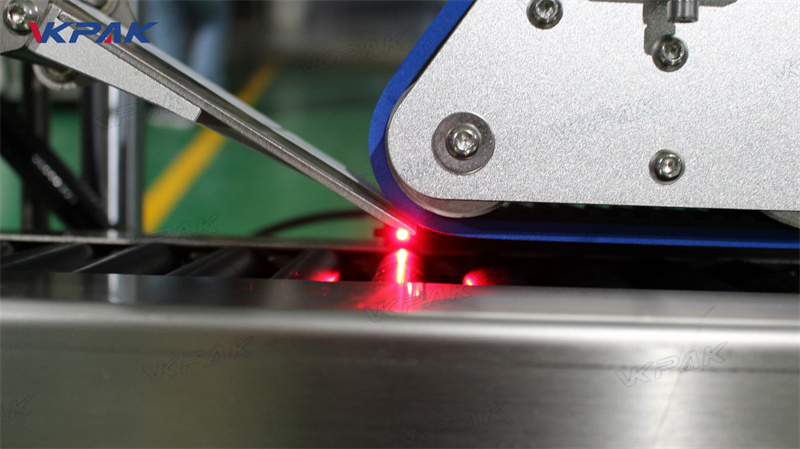

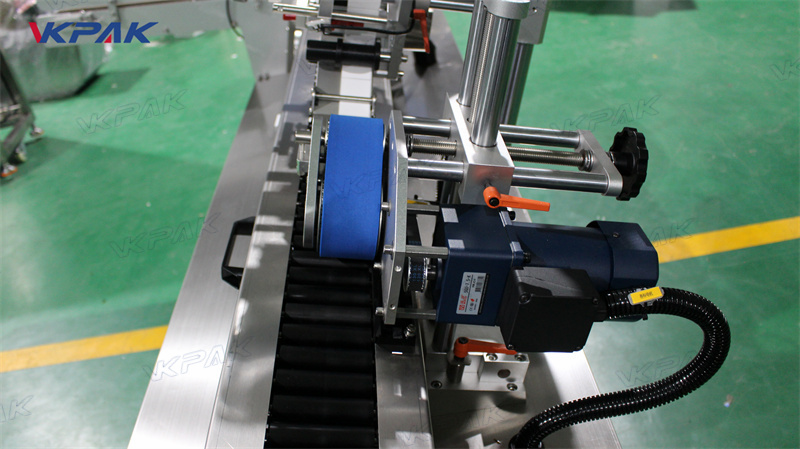

VK-HRL-H Label Sensor

This label sensor detects the presence and position of labels on the labeling machine, ensuring accurate and consistent label application on products. It offers precision in label placement, helping to minimize errors and reduce waste by preventing misaligned labels.

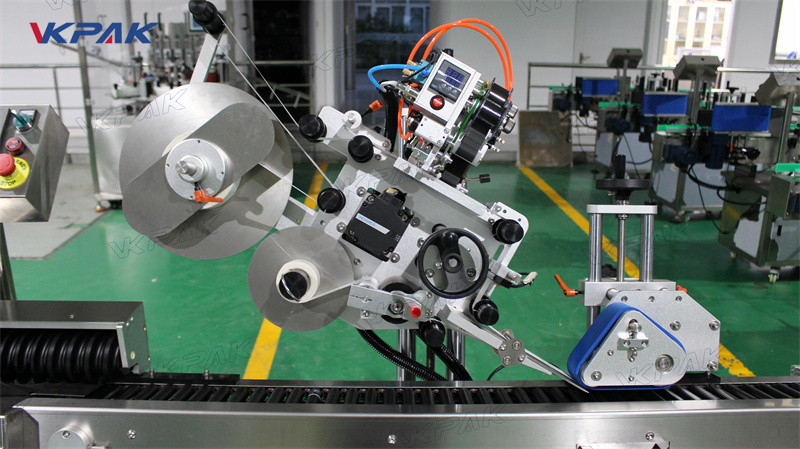

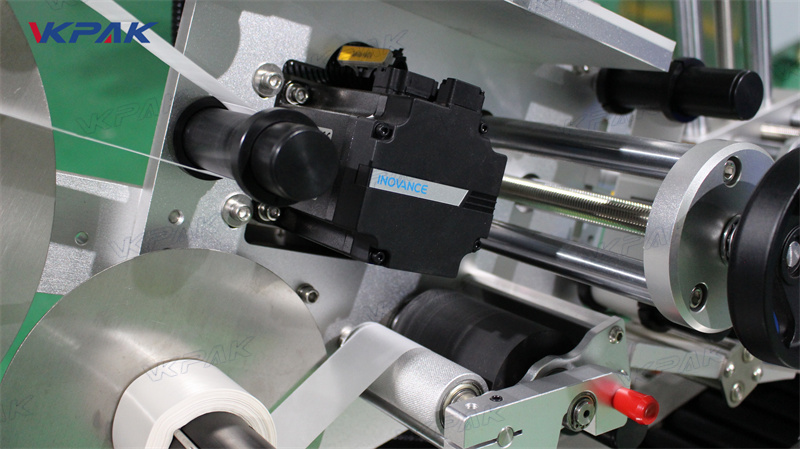

VK-HRL-H Labeling Head

The labeling head is responsible for feeding and applying labels to products as they move along the conveyor. This component is crucial for maintaining high-speed, accurate labeling, increasing productivity and providing flexibility to handle various label sizes and shapes.

VK-HRL-H Touch Screen

The touch screen interface allows operators to control and monitor the labeling machine settings easily. It enhances user convenience by simplifying adjustments, reducing setup time, and enabling quick access to parameters, which improves overall efficiency and ease of operation.

You must be logged in to post a review.

Reviews

There are no reviews yet.