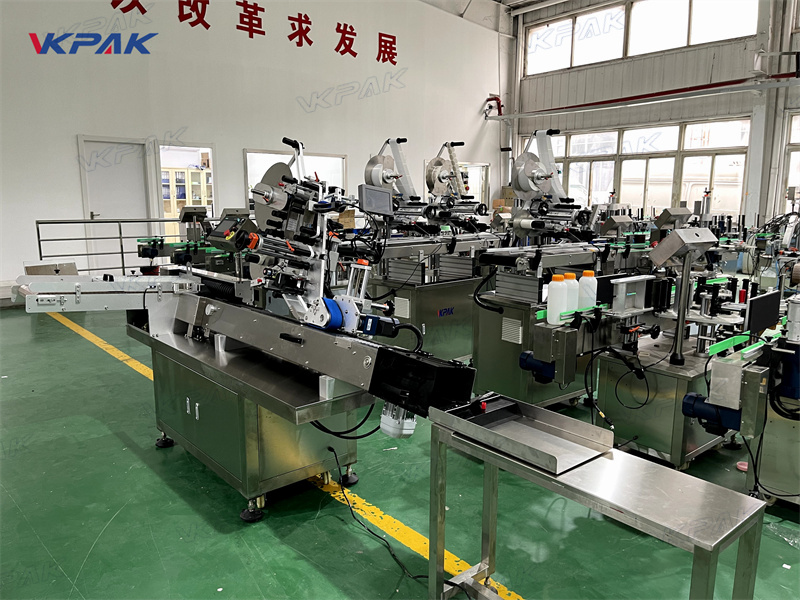

VK-HRL-HB High-Speed Horizontal Labeling Machine With Bottle Horizontal To Vertical Mechanism

$12,800.00

Tax included. Shipping calculated at checkout.

This labeling machine is based on VK-HRL-H and adds a bottle horizontal rotation mechanism. More convenient and more efficient.

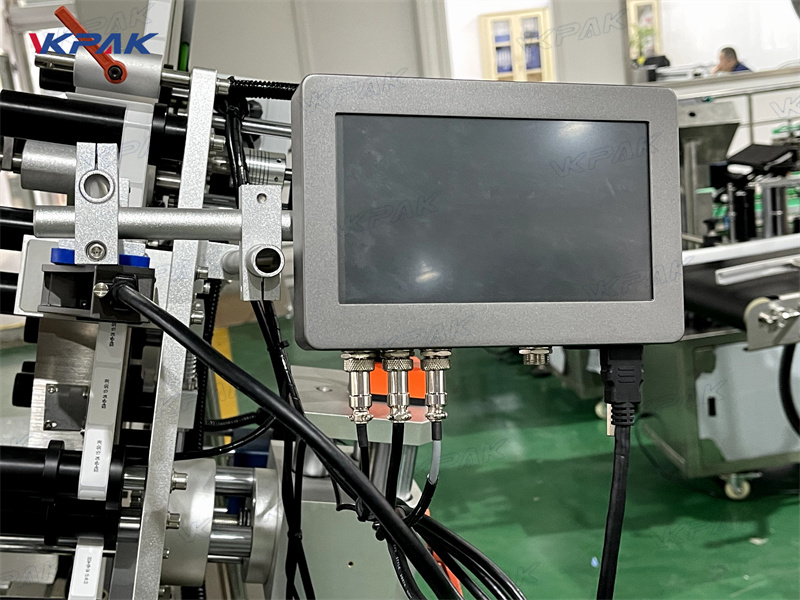

- PLC combined with human/machine interface digital LCD touch screen controller;

- Suitable for slender round bottle;

- Stainless steel frame construction and components are standard;

- Use screw to send bottle which makes smoothly and safely;

- Send bottles in the direction of vertical horizontal to feed stability, use easy and lowlabor strengh;

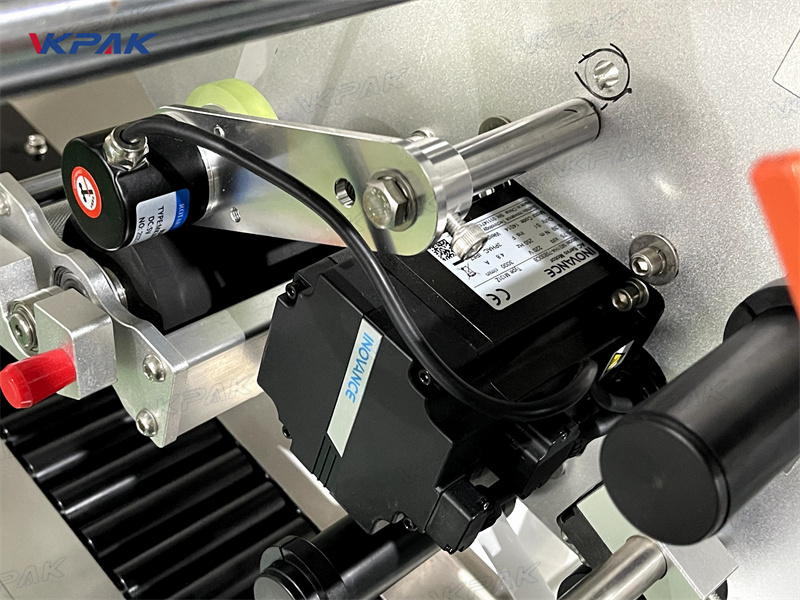

- Use sero motor to make high speed and good quality;

Output Speed: 200-600 pieces/minute depends on label and product size

Dimension: (L)3800*(W)1400*(H)1700(mm)

View Video Download PDF

Description

This labeling machine is based on VK-HRL-H and adds a bottle horizontal rotation mechanism. More convenient and more efficient.

After the vertical bottle enters the labeling machine, it automatically turns to be horizontal transported to the conveyor belt.

During the transportation process, the sensor detects the delivering products and sends a signal back to the labeling control system.

The control system controls the corresponding motor at the appropriate position to send out the label to the position where the product is to be labeled, the product goes through the label covering device, the label covering belt drives the product to rotate, the label rolling over, and the bottle automatically turns from horizontal to vertical.Finally the whole labeling process is completed.

Application

Paramenters

| Model | VK-HRL-HB |

| Labeling Speed(pcs/min) | 200-600(relate to product and label size) |

| Labeling Accuracy(mm) | ±1.0mm |

| Suitable Label Size(mm) | (L)15-80mm (H)10-80mm |

| Suitable Product Size | Diameter: 10-24mm, H:30-110mm |

| Roll Inside Diameter(mm) | Φ76mm |

| Rollouter Diameter(mm) | Φ320mm |

| Machine Size(mm) | (L)3800*(W)1400*(H)1700(mm) |

| Power Supply | AC220V50Hz/60Hz/980W |

| Operation Direction | Left To Right Or Right To Left |

| Net Weight | About 280Kg |

| Label Material | Self-Adhesive Sticker, Opaque Or Transparent Label |

Details

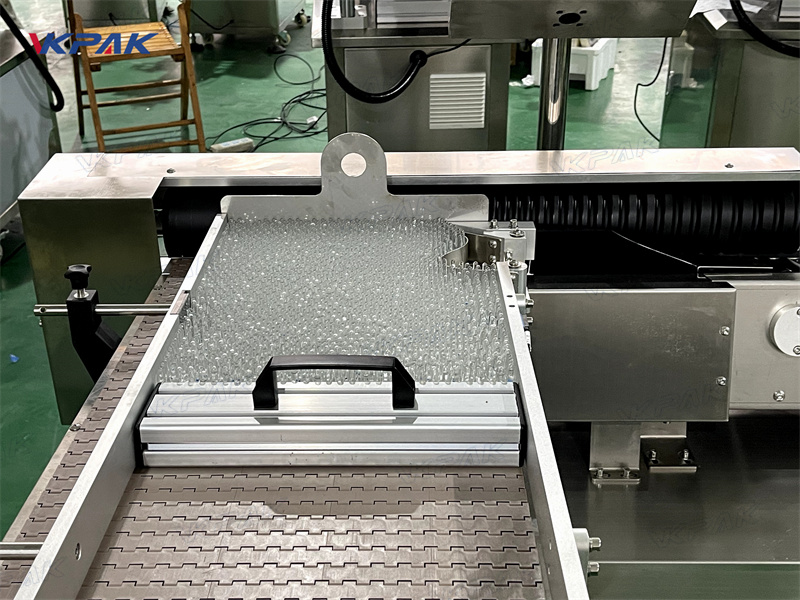

VK-HRL-HB Bottle Feeding Belt

The Bottle Feeding Belt in the labeling machine is designed to ensure a smooth and organized flow of bottles as they are fed into the labeling process. Its primary advantage is to minimize bottle jams and improve the efficiency of bottle alignment, making the labeling process faster and more consistent.

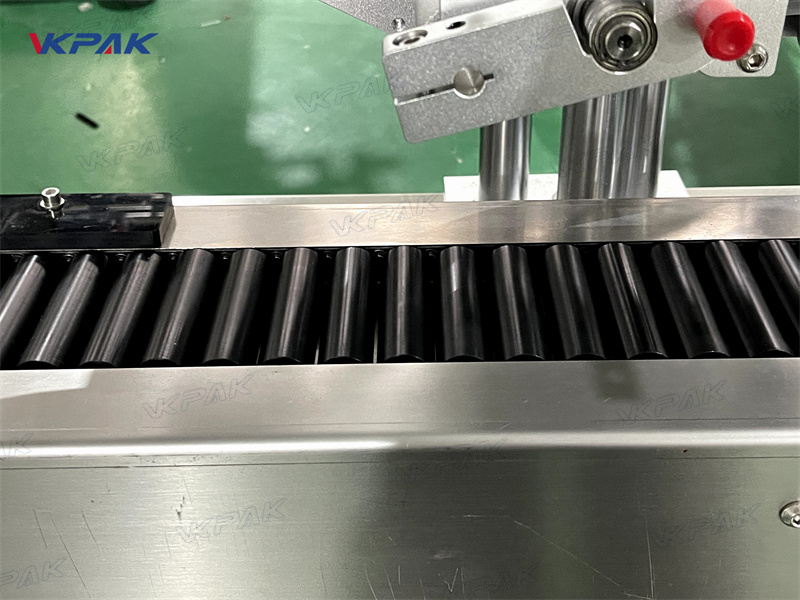

VK-HRL-HB Conveyor Belt

The Conveyor Belt is responsible for transporting bottles through various stages of the labeling process. It ensures a steady, uninterrupted flow, maintaining the right spacing between bottles to allow for accurate label application. This component increases productivity by keeping the process streamlined and reducing downtime due to misaligned bottles.

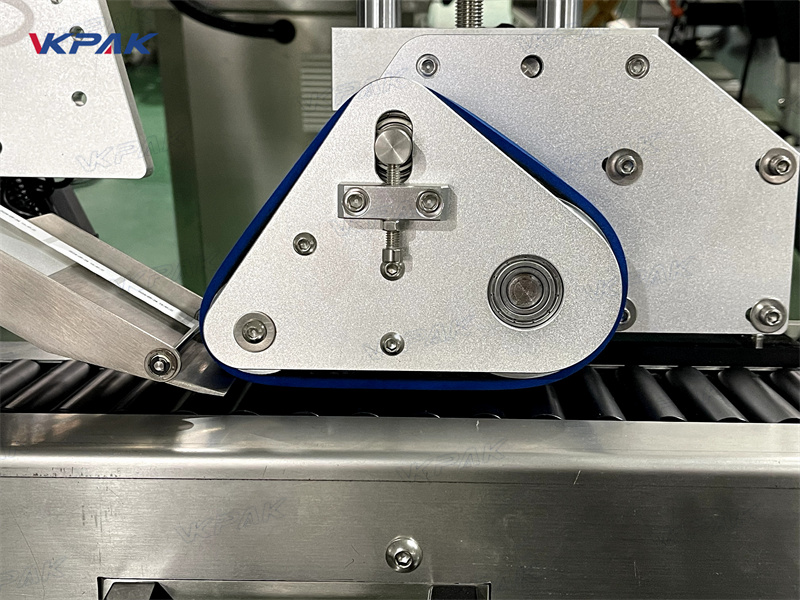

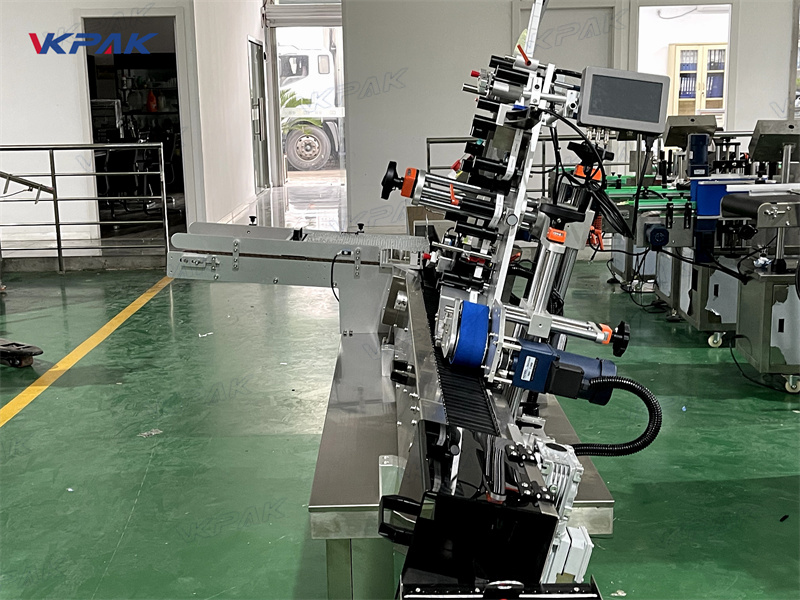

VK-HRL-HB Labeling Head

Labeling Head where labels are dispensed onto products. This component is crucial for precise label application, with adjustable rollers and guides that allow for high flexibility and accuracy, accommodating various label sizes and shapes. This design helps improve efficiency and versatility in labeling operations.

VK-HRL-HB Label Pressing Mechanism

Label Pressing Mechanism, features a pressing unit designed to apply even pressure on labels after they’re dispensed onto products. This ensures secure and accurate label placement, preventing wrinkles or misalignment, which enhances the overall presentation and adherence of the labels.

VK-HRL-HB Touch Screen

Siemens touch screen interface, which is used to control and monitor the labeling machine. It provides an intuitive user interface for setting parameters, monitoring operational status, and making adjustments. The emergency stop button and power switch enhance user safety and control, making the system user-friendly and safe for operators.

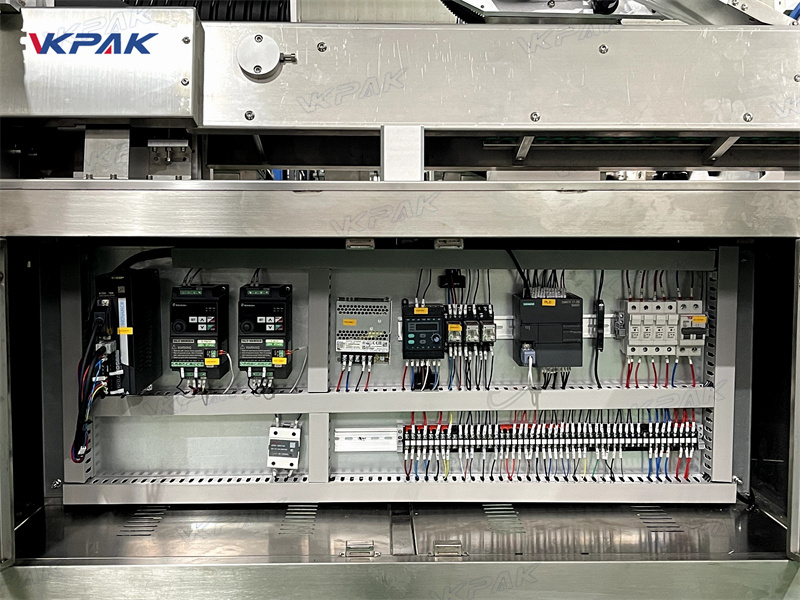

VK-HRL-HB Electrical Cabinet

The Electrical Cabinet houses all the control and power systems for the labeling machine. It contains the components necessary for controlling the machine’s operations, such as motor drives, sensors, and programmable logic controllers (PLCs). This cabinet improves operational reliability by organizing and protecting essential electronics, ensuring precise control, and reducing the risk of component failure or accidental damage.

You must be logged in to post a review.

Reviews

There are no reviews yet.