VK-OSL Automatic Single Side Flat Square Wine Olive Oil Bottle Labeling Machine

$8,600.00

Tax included. Shipping calculated at checkout.

The single side labeling machine is suitable for the application of labels to single sides of flat bottles, round bottles, and square bottles. It features a maximum production speed of 150 pcs/min.

Output Speed: 30-150 pieces/minute depends on label and product size

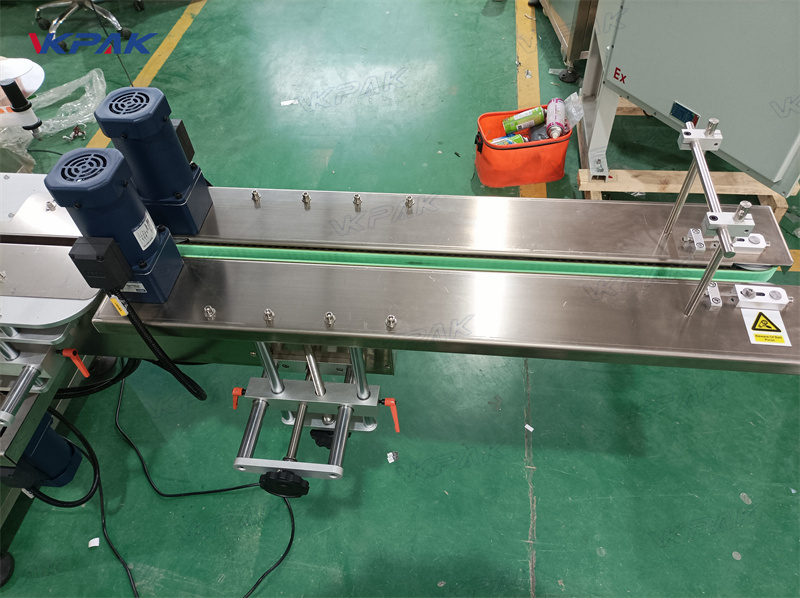

Dimension: (L)2800*(W)1100*(H)1600(mm)

View Video Download PDF

Description

This automatic bottle labeling machine is designed for label self-adhesive stickers on flat or square bottles like wine, olive oil, dishwashing liquid, liquid soap, laundry detergent, mouthwashes.

Suitable for single side labeling on flat or square bottles.

Label sensor can be customized for detecting transparent label stickers.

Date coder is optional, can be bought separately to print batch number and production date on stickers.

PLC control panel allows operator to make customizable interface and make operation more convenient.

Can work separately or be connected with filling and capping machine to realize complete production work.

Application

Paramenters

| Model | VK-OSL |

| Labeling Speed(pcs/min) | 30-150(relate to product and label size) |

| Labeling Accuracy(mm) | ±1.0mm |

| Suitable Label Size(mm) | (L)10-300mm (H)10-150mm(Customizable) |

| Suitable Product Size | Diameter: 10-250mm, H:30-400mm(Customizable) |

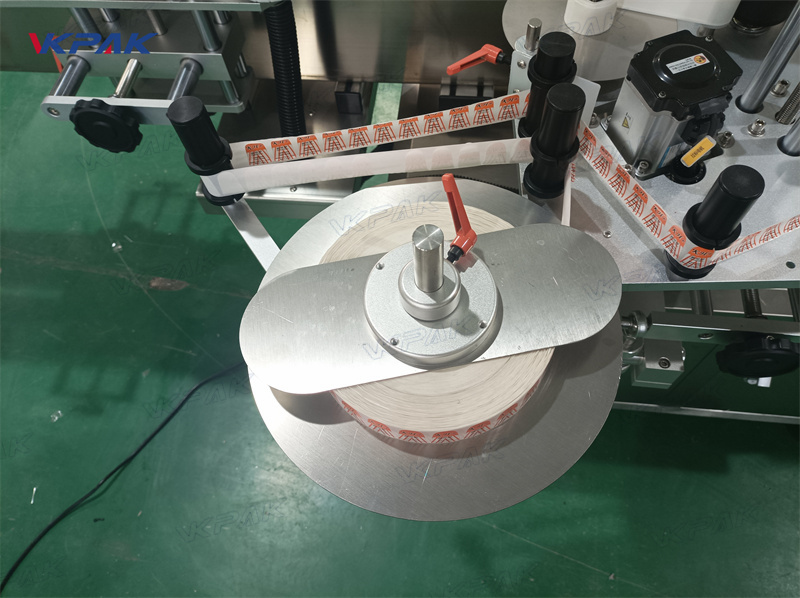

| Roll Inside Diameter(mm) | Φ76mm |

| Rollouter Diameter(mm) | Φ320mm |

| Machine Size(mm) | (L)2800*(W)1100*(H)1600(mm) |

| Power Supply | AC220V 50Hz/60Hz (Customizable) |

| Operation Direction | Left To Right Or Right To Left |

| Net Weight | About 250Kg |

| Label Material | Self-Adhesive Sticker, Opaque Or Transparent Label |

Details

VK-OSL Touch Screen

The control panel provides an intuitive interface for operators to configure and monitor the labeling machine’s performance. With a user-friendly design and real-time display of key metrics, it simplifies operation and troubleshooting. The emergency stop feature enhances safety, and customizable settings improve operational flexibility.

VK-OSL Electrical Cabinet

The electrical cabinet of the labeling machine, housing the core electrical and control components. This organized system includes drives, relays, power supplies, and programmable logic controllers (PLCs), which work together to manage and automate the machine’s operations. The neatly arranged design improves accessibility for maintenance and ensures stable, reliable performance.

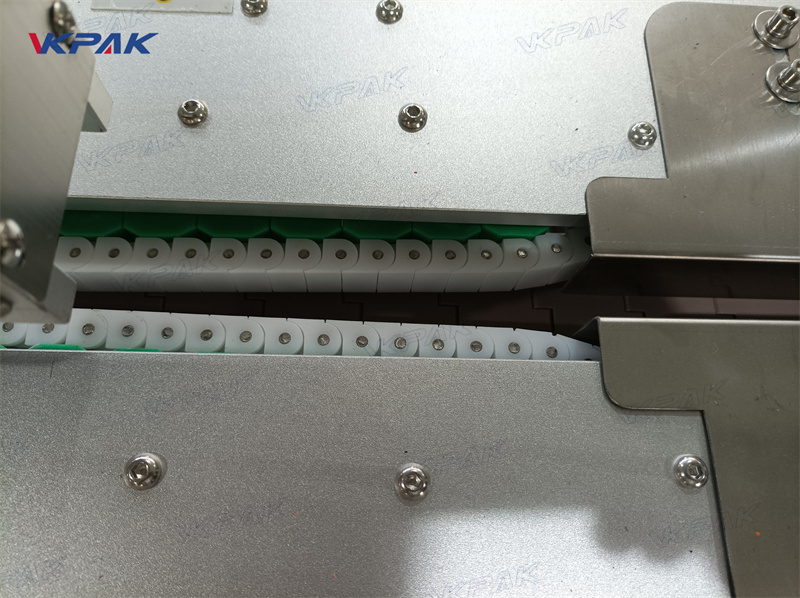

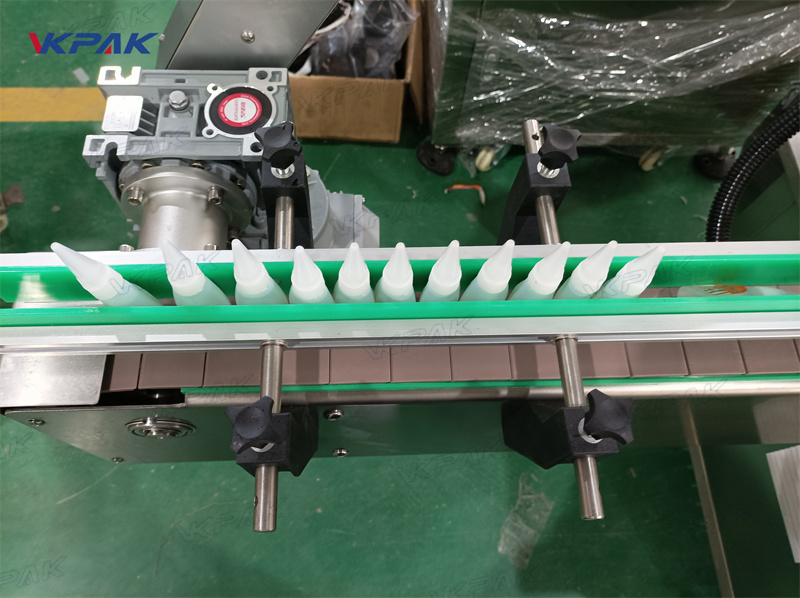

VK-OSL Bottle Clamping Belt

The bottle clamping belt, which is crucial for securing bottles during the labeling process. It ensures precise alignment and consistent label application by preventing the bottles from moving or tilting as they pass through the labeling system. The belt’s durable and adjustable design allows it to handle various bottle sizes, enhancing versatility and efficiency in production.

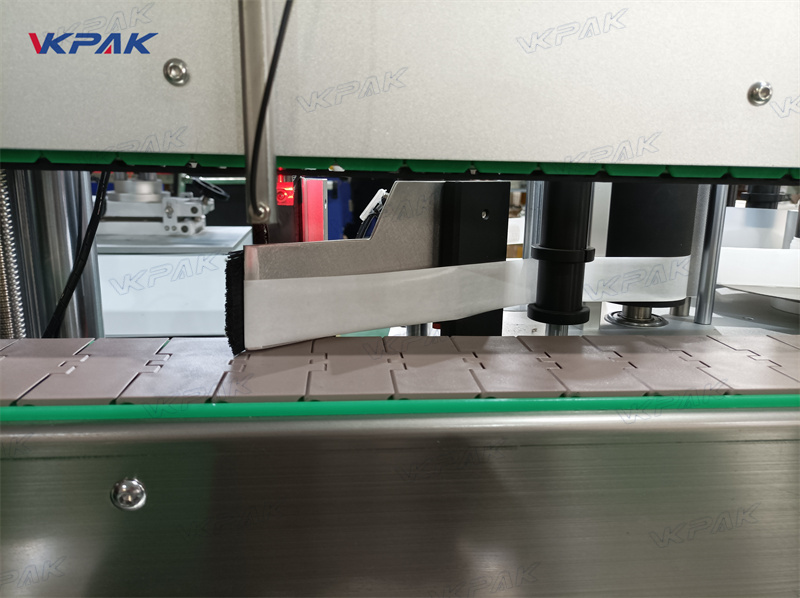

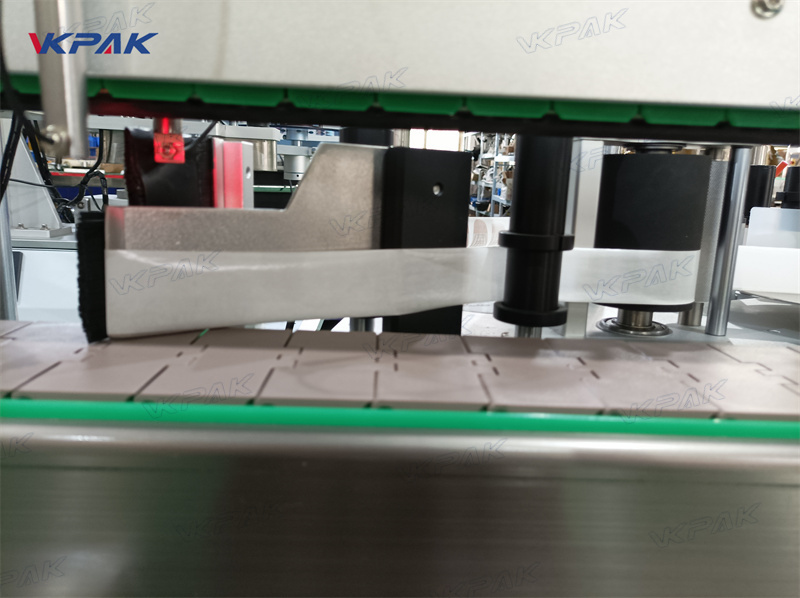

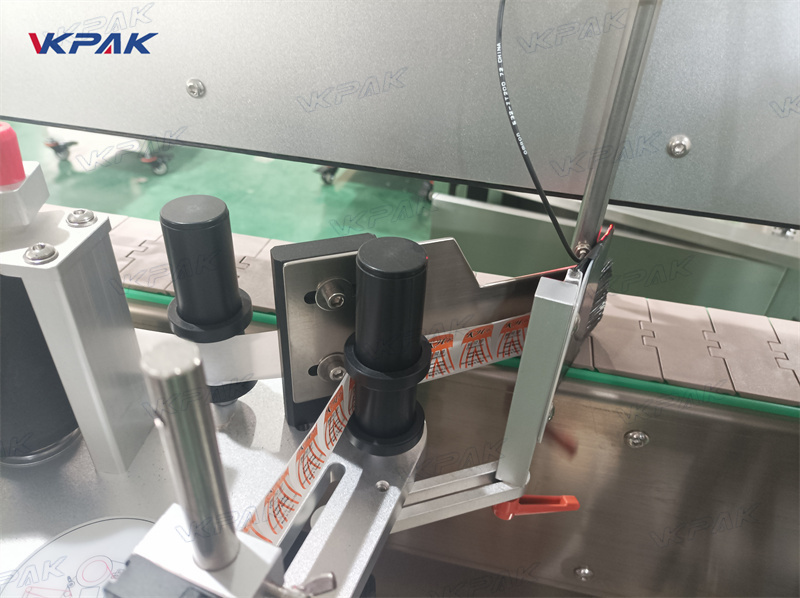

VK-OSL Label Peeling Knife

The label peeling knife, designed to separate labels from their backing material with precision. This component plays a vital role in enabling smooth and accurate label dispensing. Its robust construction and sharp edge contribute to reducing label misalignment or tearing, thus ensuring high-quality labeling at high speeds.

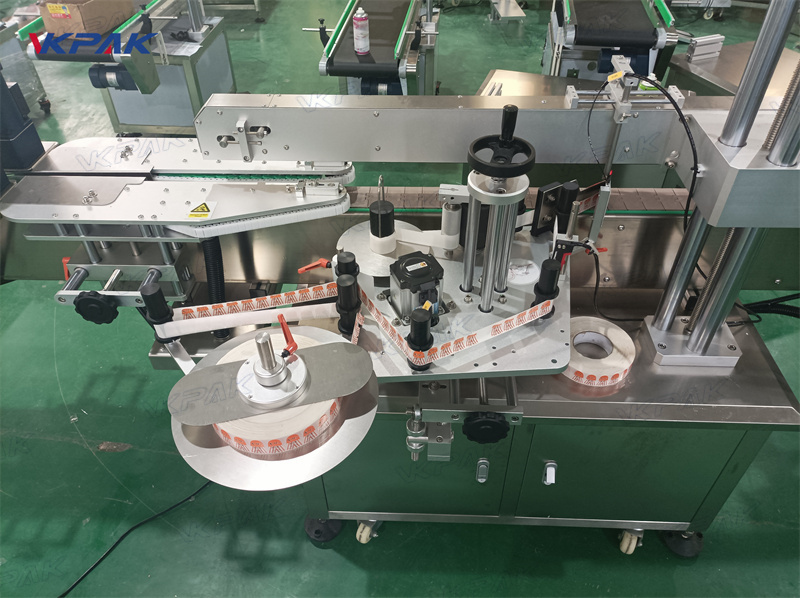

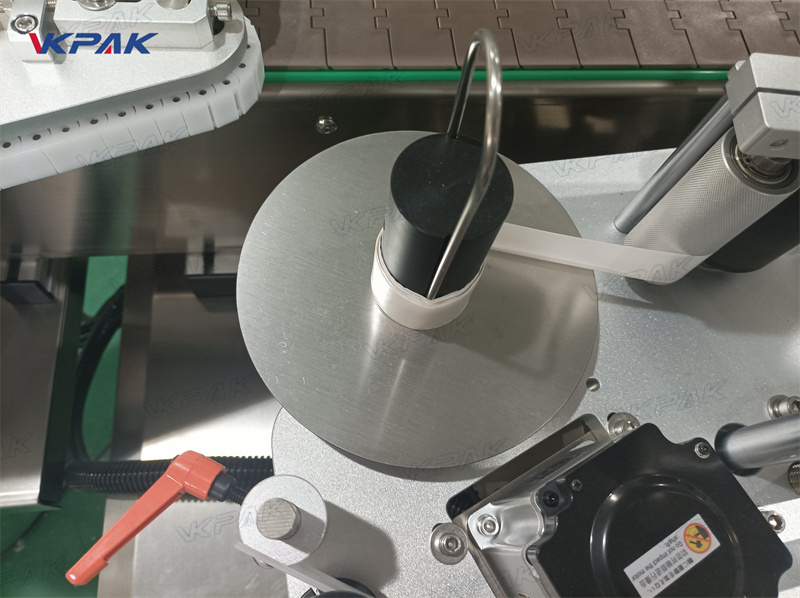

VK-OSL Labeling Head

Labeling head is responsible for applying labels to products accurately. Its design facilitates precise placement and handling of labels, ensuring consistency and reducing errors in the labeling process. It also allows for easy adjustment and supports high-speed operations, enhancing productivity.

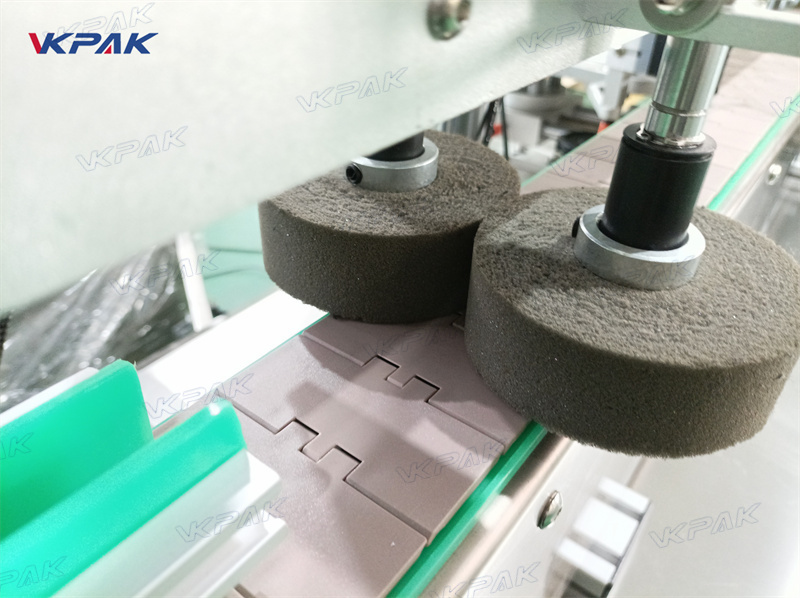

VK-OSL Pressure Label Sponge Wheel

Pressure label sponge wheel helps secure the label onto the product surface by applying consistent pressure. The sponge material ensures that the labels adhere smoothly without wrinkles or air bubbles, especially on irregular surfaces. It also minimizes product damage due to its soft and adaptive texture.

You must be logged in to post a review.

Reviews

There are no reviews yet.