VK-RPL-B Automatic Three Roller Plastic Empty Pail Bucket Labeling Machine

$6,000.00

Tax included. Shipping calculated at checkout.

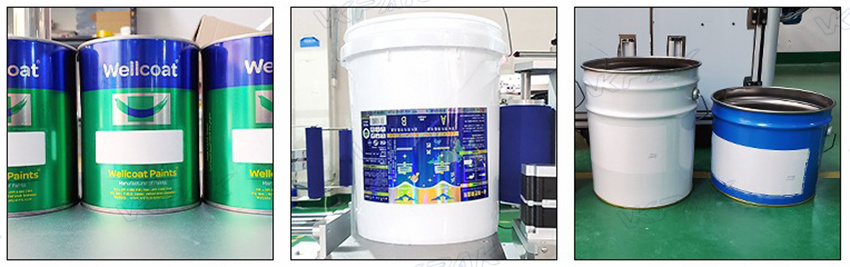

This label applicator machine is customized for labeling self-adhesive sticker on large bucket with handle. Single side, double sides and wrap-around labeling are available, this machine can be used for packaging liquid fertilizers or oil paint bucket.

Output Speed: 10-20 pieces/minute depends on label and product size

Dimension: (L)2000*(W)1300*(H)1200(mm)

View Video Download PDF

Description

This labeling machine is specially designed for bucket or large round containers based on VK-RPL. It also adopts a three-roller bottle clamping design and can apply single-sided, double-sided or full-circle wrapping labels.

Application

Paramenters

| Model | VK-RPL-B |

| Labeling Speed(pcs/min) | 10-20(relate to product and label size) |

| Labeling Accuracy(mm) | ±1.0mm |

| Suitable Label Size(mm) | (L)10-750mm (H)10-300mm |

| Suitable Product Size | Diameter: 100-250mm, H:50-600mm |

| Roll Inside Diameter(mm) | Φ76mm |

| Rollouter Diameter(mm) | Φ320mm |

| Machine Size(mm) | (L)2000*(W)1300*(H)1200(mm) |

| Power Supply | AC220V50Hz/60Hz/980W |

| Operation Direction | Left To Right Or Right To Left |

| Net Weight | About 350Kg |

| Label Material | Self-Adhesive Sticker, Opaque Or Transparent Label |

Touch Screen Control Panel: Customizable interface simplifies machine operation

Handle Holding Structure: Keep the handle upright so that labeling can be processed

Labeling Structure: Three roller labeling suits single/double sides/wrap-around labeling

Adjusting Knob: The position of the labeling components can be adjusted flexibly in multiple directions

Wider Conveyor: Chain conveyor has larger weight capacity, width can be customized

Details

VK-RPL-B Bucket Queuing Mechanism

This component ensures products are aligned and spaced accurately before labeling. Its advantage lies in maintaining a consistent flow, minimizing product collisions, and ensuring precise label placement.

VK-RPL-B Clamping Mechanism

This unit stabilizes products during the labeling process, holding them firmly in place. The clamping mechanism enhances accuracy and prevents misalignment.

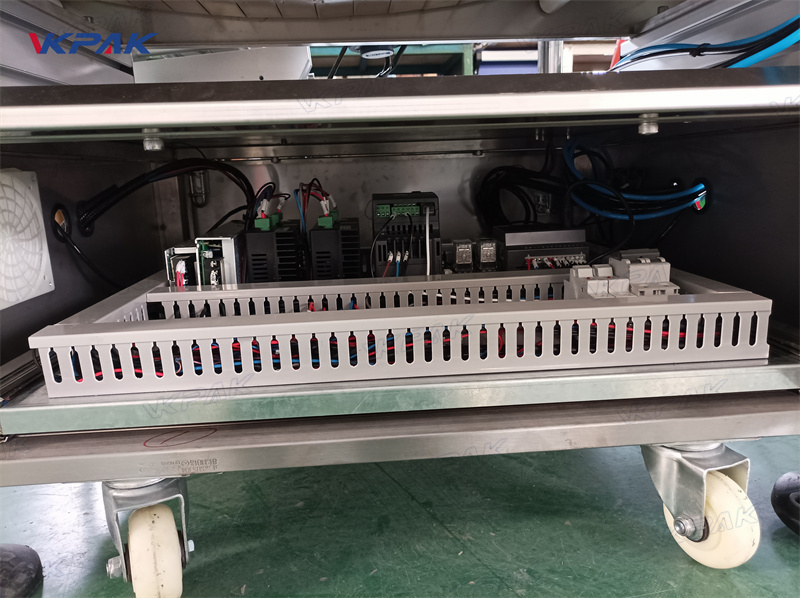

VK-RPL-B Electrical Cabinet

Housing the control and power systems, the cabinet organizes and protects critical electrical components like drives, relays, and controllers. Its structured design simplifies maintenance, improves safety, and ensures reliable operation of the labeling machine.

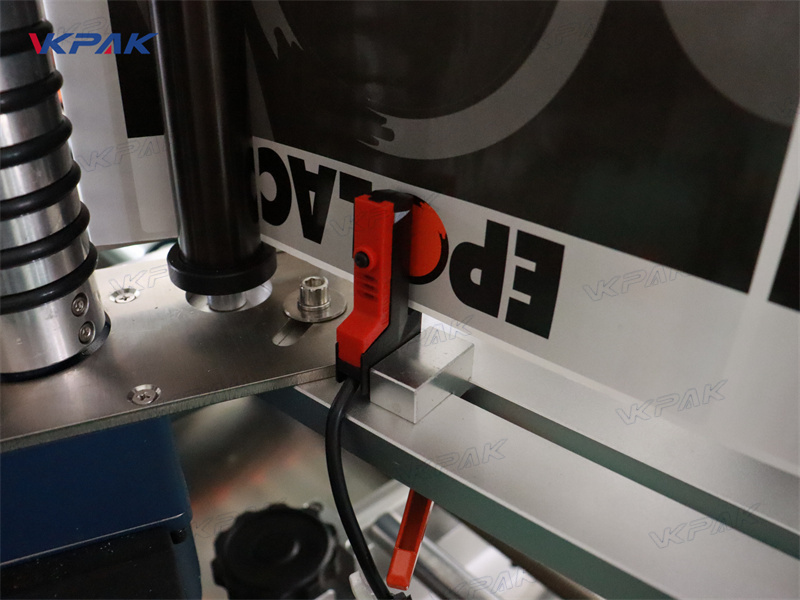

VK-RPL-B Label Sensor

This component detects labels on the label roll with precision, ensuring accurate placement during the labeling process. Its advantage lies in its reliability and ability to handle varying label sizes and designs, reducing errors and increasing efficiency.

VK-RPL-B Label Support Mechanism

This part stabilizes and guides the labels as they are dispensed onto the product, ensuring smooth and consistent application. Its robust design improves alignment accuracy and minimizes label misplacement.

VK-RPL-B Touch Screen

The user interface for controlling the labeling machine, this component provides an intuitive platform for operators to adjust settings, monitor operations, and troubleshoot issues. The advantage of this touch screen is its ease of use and real-time feedback, enhancing operational efficiency and reducing downtime.

You must be logged in to post a review.

Reviews

There are no reviews yet.