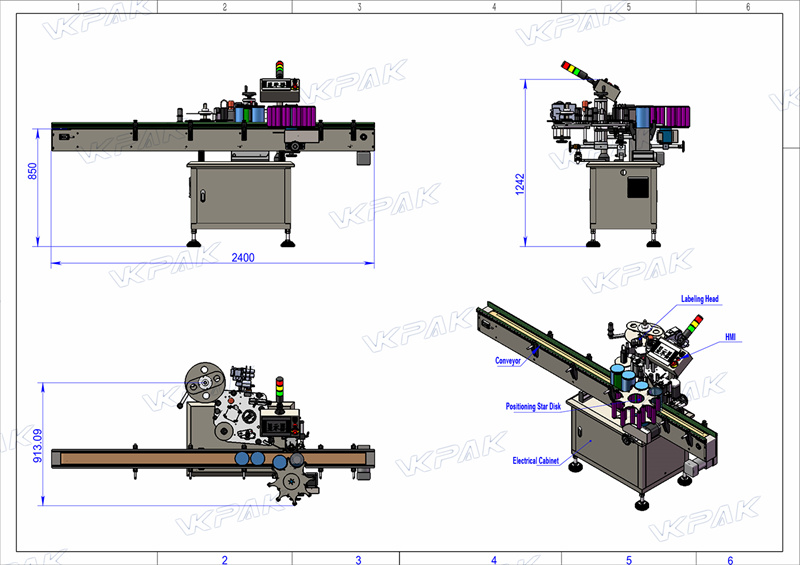

VK-SPL Automatic Chocolate Sauce Cream Round Bottle Star Wheel Labeling Machine

$6,900.00

Tax included. Shipping calculated at checkout.

The labeling structure is designed with star wheel, compared with other round bottle labeling machine, it removes he bottle separating wheel (which is used to control the distance between bottles and bottles during conveying). The labeling speed and labeling speed are greatly improved while machine debugging becomes easier. This labeler is more suitable for small diameter cylinder. It is the ideal choice for larger scale production in food, cosmetics and daily chemical industries.

- Design with a star wheel to feed labeling objects, this can improves working capacity and labeling accuracy.

- With the change in bottle diameter, Starwheel on the machine has to be changed.

- Suitable for full or partial wrap around labelling on different sizes of round containers.

- It can work with high speed filling and capping machine to realize automated production.

Output Speed: 30-70 pieces/minute depends on label and product size

Dimension: (L)2400*(W)1300*(H)1600(mm)

View Video Download PDF

Description

This labeling machine is mainly designed for round bottles, its labeling structure is consist of multiple rollers, this kind of labeling method can greatly improve working capacity and labeling accuracy. It is widely used in food, daily chemical, and cosmetics industries.

Suitable for round bottle in different sizes labeling on bottle special position.

Suitable for labeling on the circumference of round bottles, single and double labels can be affixed, and the spacing between the front and back double labels can be flexibly adjusted, such as labeling on round bottles of jelly, round cans of foodstuffs, etc., which are widely used in the industries of cosmetics, foodstuffs, pharmaceuticals, and disinfectant water.

Paramenters

| Model | VK-SPL |

| Labeling Speed(pcs/min) | 30-70(related to bottle and label size) |

| Labeling Accuracy(mm) | ±1.0mm |

| Suitable Label Size(mm) | (L)10-300mm (H)20-250mm |

| Suitable Bottle Size | Diameter: 25-130mm, H: 20-300mm |

| Roll Inside Diameter(mm) | Φ76mm |

| Roll Out Diameter(mm) | Φ320mm |

| Machine Size(mm) | (L)2400*(W)1300*(H)1600(mm) |

| Power Supply | AC220V 50Hz/60Hz |

| Operation direction | left to right or right to left |

| Net weight | About 350Kg |

| Label material | self-adhesive sticker, opaque or transparent label |

Application

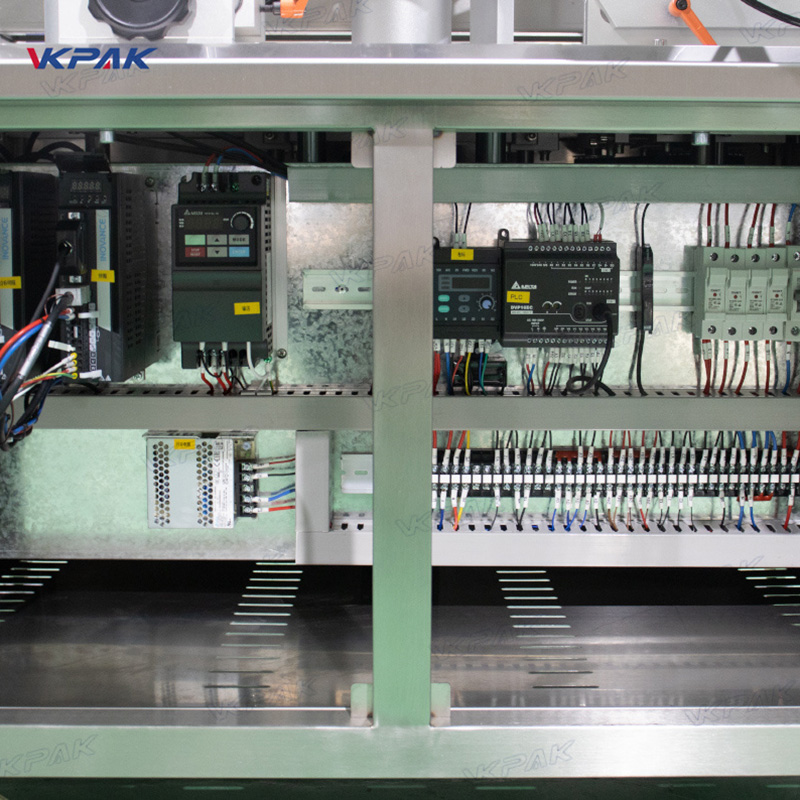

The touch screen control panel integrates the control of the whole machine, making the adjustment of machine working data more convenient and intuitive. In addition, the operating language of the control panel can be programmed according to the actual operating needs.

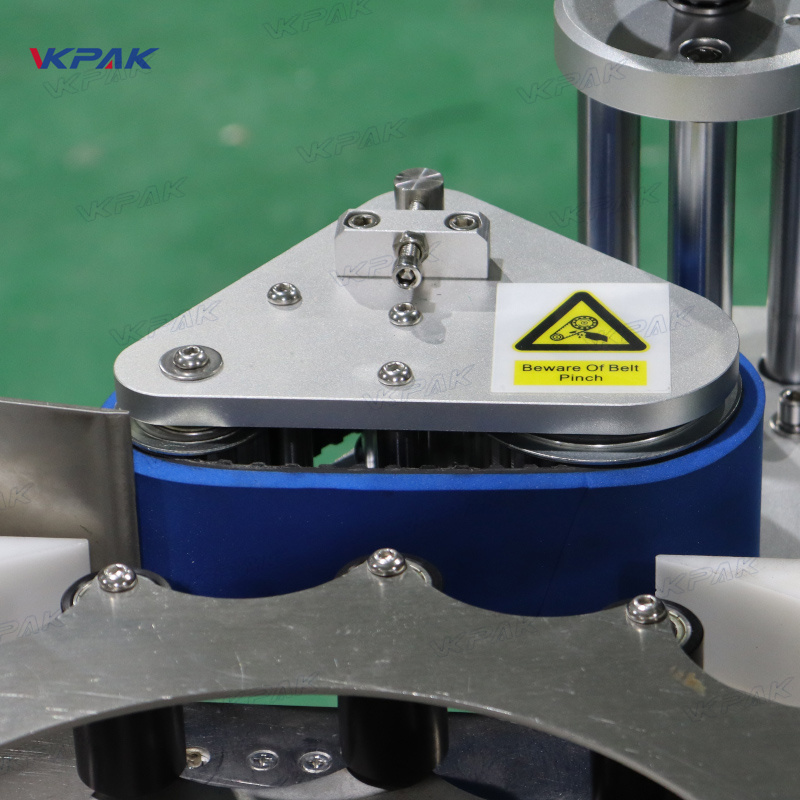

The star wheel is used to replace the bottle baffle to realize the bottle dividing function, this can improves working capacity and labeling accuracy.

The sensor can detect passing by bottles and send signal to control system, the machine will start the labeling work. With this component, the labeler can realize automated work and reduce labeling error.

The chain conveyor is with larger weight capacity, it ensure products can be conveyed smoothly. The width of conveyor belt can be customized as production need.

The label sensor is used to detect labels so the machine can be controlled to output label stickers or not. The sensitivity can be adjusted according to label stickers material.It improves working accuracy.

You must be logged in to post a review.

Reviews

There are no reviews yet.