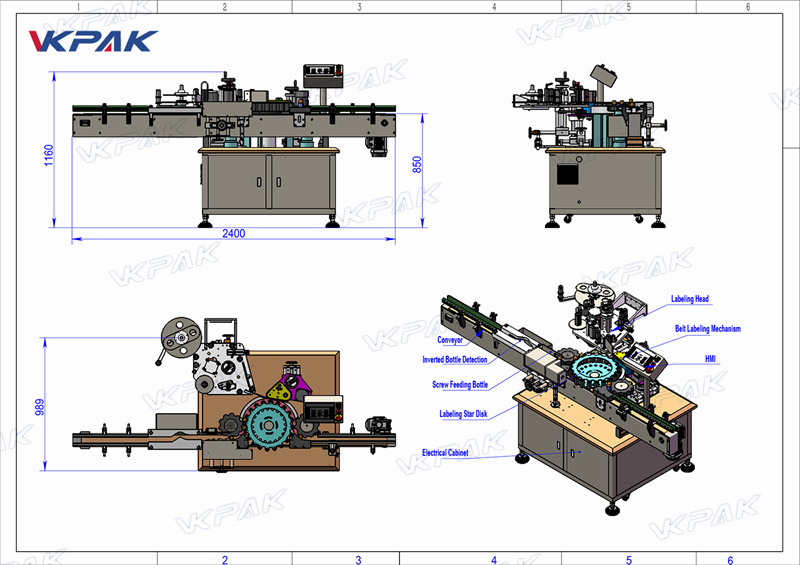

VK-SPL-B High Speed Vertical Star Disk Small Vial Medicine Bottle Sticker Labeling Machine

$8,500.00

Tax included. Shipping calculated at checkout.

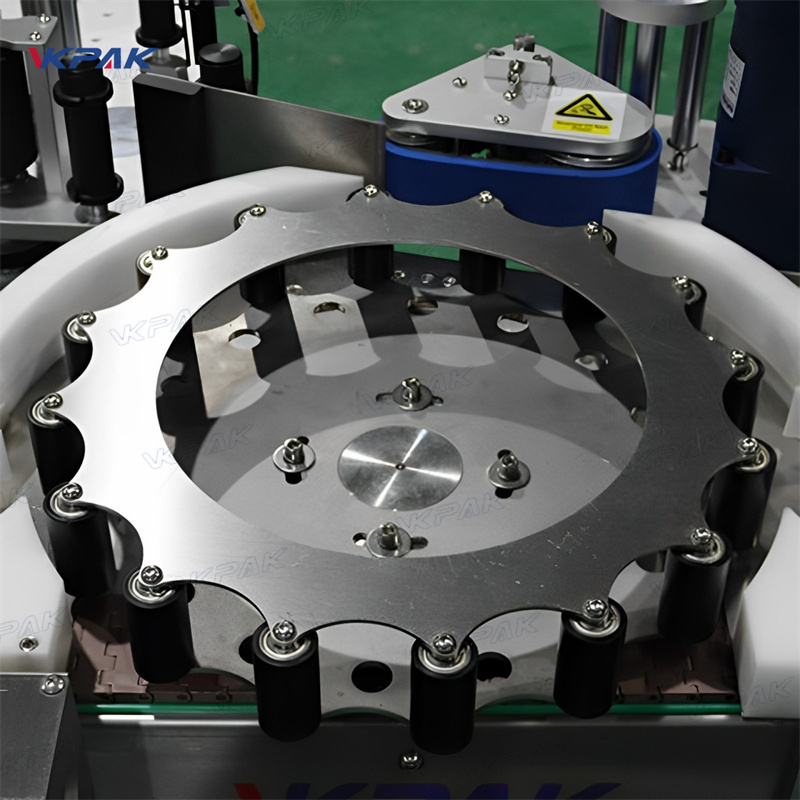

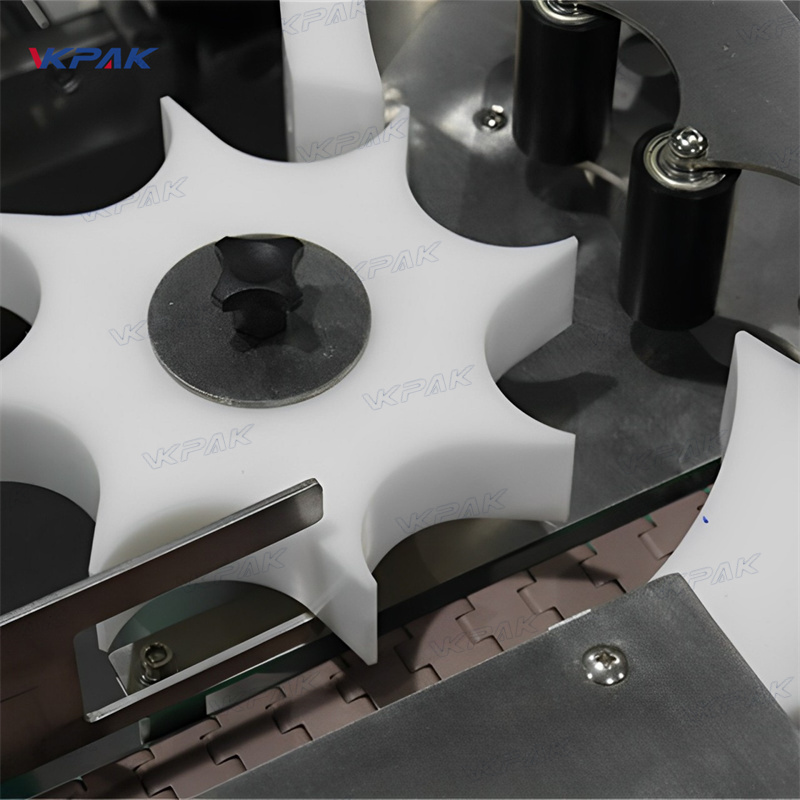

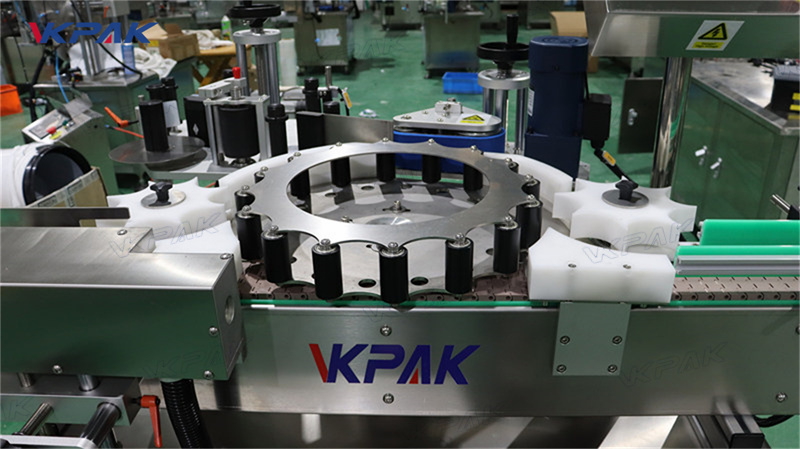

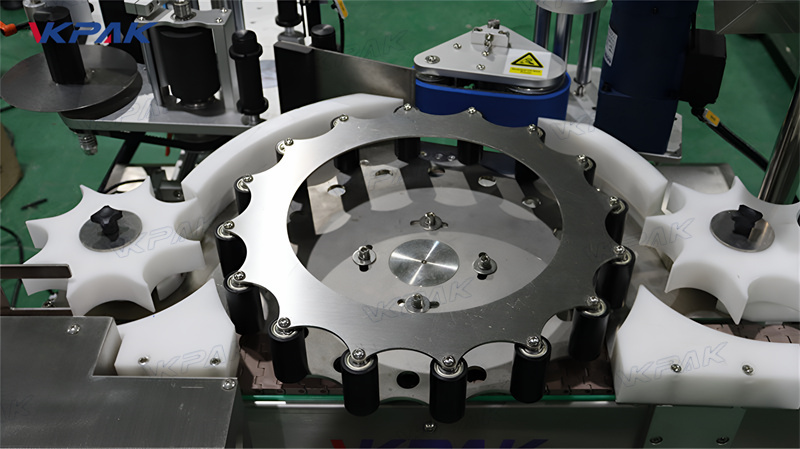

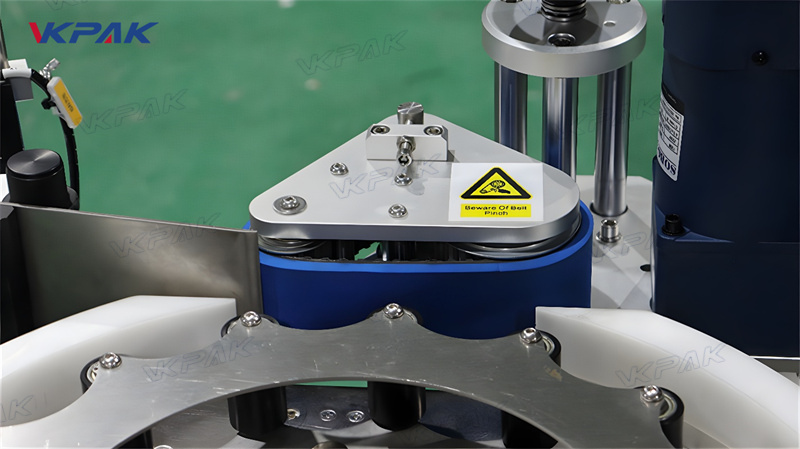

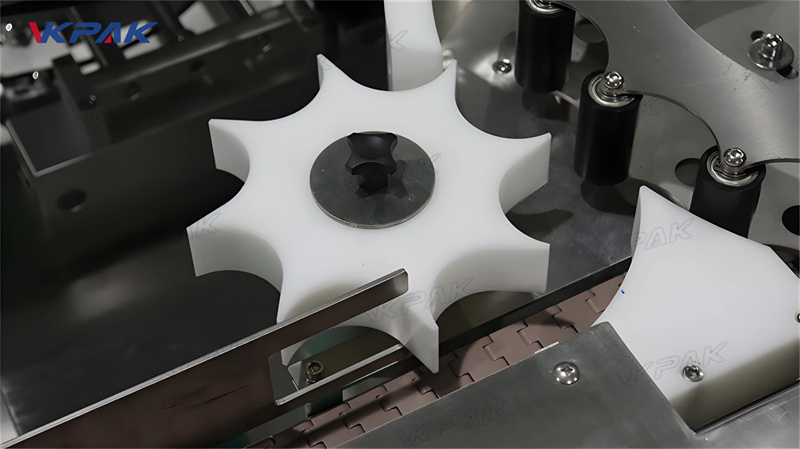

This model of labeling machine is an upgraded design based on VK-SPL-S. It uses a large star plate and two auxiliary small star plates to form a three-star disk labeling machine. The labeling speed is faster. The screw bottle feeding ensures that the batch of bottles enters the labeling station stably and orderly.

This labeling machine is suitable for high-precision and high-speed labeling of various small bottles.

Output Speed: 100-300 pieces/minute depends on label and product size

Dimension: (L)2400*(W)1300*(H)1600(mm)

View Video Download PDF

Description

This series of products is suitable for medicine, daily chemical, food and other industries, and the cylindrical object is fully or semi-circular automated high-speed labeling; it adopts a return star disk rotating structure. The bottle is put in, pasted, and taken out, which greatly improves the qualified rate of labeling.

Working Process

Core principle: Sorting the product by bottle wheel, putting the product on the conveyor belt,sensors detect the product after, back to the signal to the labeling control system, in the appropriate position control system control corresponding motor send labels and attached with a stay in product labeling position, The product goes through the labeling device,the label belt drives the product to rotate, the label is rolled over, and the attached action of a label is completed.

Bottle through a conveyor belt into the chart, by measuring the bottle of magic eye, triggering a bottle of magic eye to the PLC signal measurement, PLC after time delay control dial clockwise (a work place, when the bottle in the stroke scale roll position, the bottle at the bottom of the bottle label test electric eye to see the bottle, at the same time, the bottle with stroke the roller has been spinning clockwise (in situ, check the labeling bottles of magic eye to the PLC a signal, when the orientation of the bottle at the bottom of the magic eye to see the bottle at the bottom of the sign, positioning magic eye and give a signal of PLC, the PLC control to the delay of a label on the bottle, at the same time in the stroke with the cooperation of the roller,Stick the whole label firmly on the surface of the bottle. After sticking, the star puller turns clockwise one working bit, and the bottle is transported out to complete the whole labeling process.

Precision and versatility are key advantages of vial sticker labeling machine. These machines feature user-friendly control panels that allow operators to set parameters such as label positioning, labeling speed, and label detection sensitivity. The ability to adjust these parameters ensures accurate label placement on various vial sizes and shapes, accommodating different label designs, languages, and regulatory requirements. Some machines also offer options for multiple label application or the inclusion of variable data such as barcodes or serial numbers.

Paramenters

| Model | VK-SPL-B |

| Labeling Speed(pcs/min) | 100-300(related to bottle and label size) |

| Labeling Accuracy(mm) | ±1.0mm |

| Suitable Label Size(mm) | (L)10-300mm(H)20-250mm |

| Suitable Box Size | Diameter: 25-130mm , H:20-300mm |

| Roll Inside Diameter(mm) | Φ76mm |

| Roll Out Diameter(mm) | Φ300mm |

| Machine Size(mm) | (L)2400*(W)1300*(H)1600(mm) |

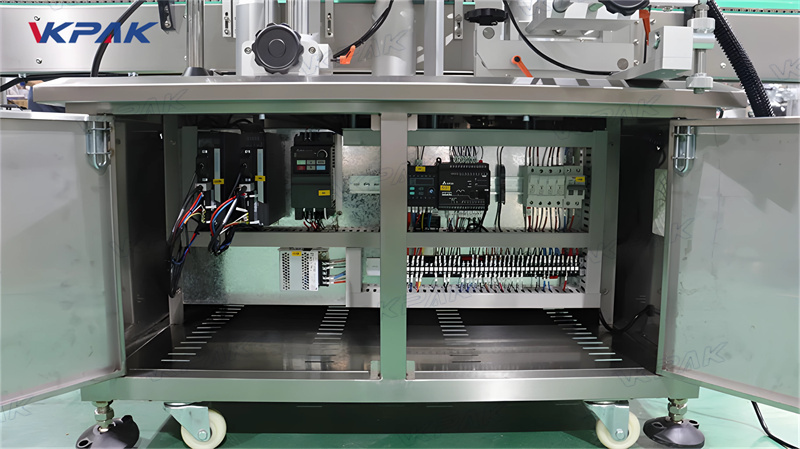

| Power Supply | AC220V 50Hz/60Hz |

| Operation direction | left to right or right to left |

| Net weight | About 350Kg |

| Label material | self-adhesive sticker, opaque or transparent label |

The Main Features

The motor adopts panasonic servo labeling system, delta PLC and function module, panasonic servo main motor marking, delta frequency conversion regulation: high stability and synchronization, the fastest reaction speed of 1200 times/minute, and strong torque, never out of step.

Germany Siemens microcomputer control system:

Real FUZZY(intelligent) no setting, no adjustment, as long as the boot, the system has completed all labeling calculus and preparation, press the start button to paste the perfect product.

Operation mode:

The imported touch-control man-machine interface is adopted, and the display is all in Chinese. As long as the operation is conducted according to the instructions on the display screen, no experience is required, it can be easily put online, greatly reducing the training time of personnel;Through the man-machine interface, the production speed can be set at will, and the production speed can be adjusted automatically.

If there is any abnormal fault: if the label is used up, the band is broken or tension is missed, the counting setting arrives, the machine is abnormal and so on, it will automatically stop the machine and give an alarm.

Application

Suitable for round bottle in different sizes labeling on bottle special position;

Suitable for labeling on the circumference of round bottles, single and double labels can be affixed, and the spacing between the front and back double labels can be flexibly adjusted, such as labeling on round bottles of jelly, round cans of foodstuffs, etc., which are widely used in the industries of cosmetics, foodstuffs, pharmaceuticals, and disinfectant water.

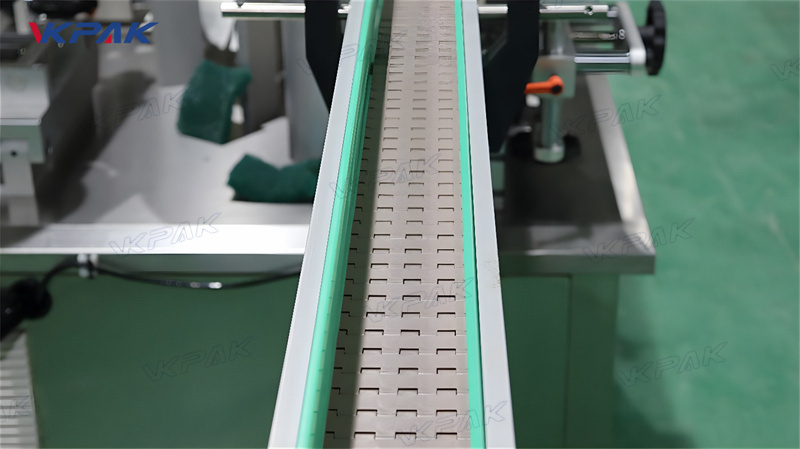

The conveyor belt is suitable for different sizes of products, the width between the conveyor belt can be adjusted according to your products, to ensure the smooth and safe movement of products on the conveyor belt.

Equipped with sensors, when there is a product through, sensitive recognition, through the internal system to send signals to the labeling station.

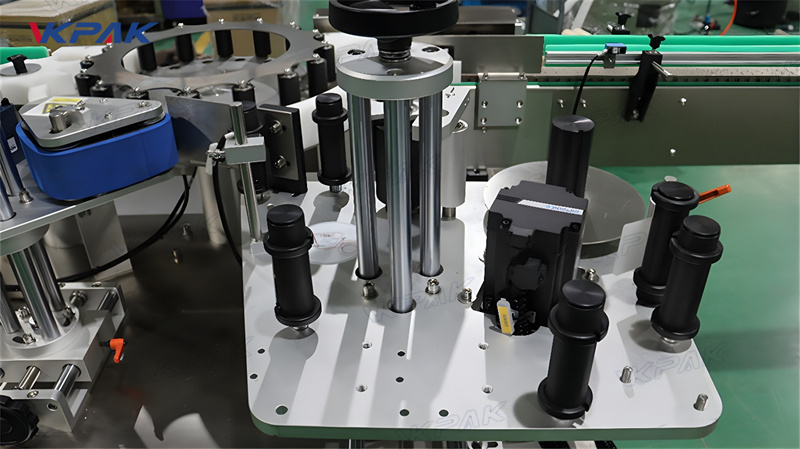

Mechanical Design:

Super wear-resistant label rolling mechanism, using duralumin sandblasting, durable and not easy to wear.

Accurate differential bottling mechanism, the bottling accuracy is as high as ±5mm, it is unnecessary to change accessories for bottles of different specifications, saving cost, easy to adjust, and better than other brands.

The stable and durable frame and various parts adopt standardized modular design with complete interchangeability and operate 24 hours a day to ensure safety and stability.

The case, made of stainless steel SUS304 and T6 aluminum alloy, never rusts and complies with GMP standard.

The printing head adopts the solenoid valve to control the cylinder for reciprocating movement. Compared with the movement mode of crank connecting rod, the reaction speed and printing speed are greatly improved.

The printable manufacturing date, production batch number and expiry date can be completed at the same time, and the printing direction can be adjusted according to user needs.The writing is clear and clean.

You must be logged in to post a review.

Reviews

There are no reviews yet.