VK-STL Automatic Empty Squeeze Tube Labeling Machine

$14,000.00

Tax included. Shipping calculated at checkout.

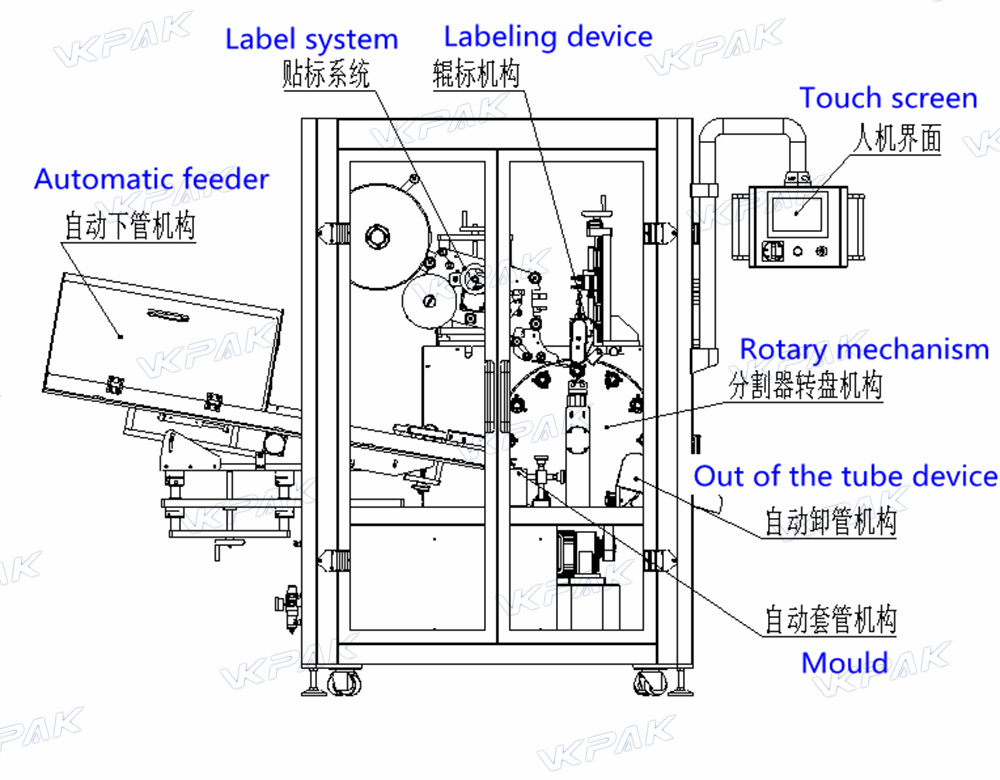

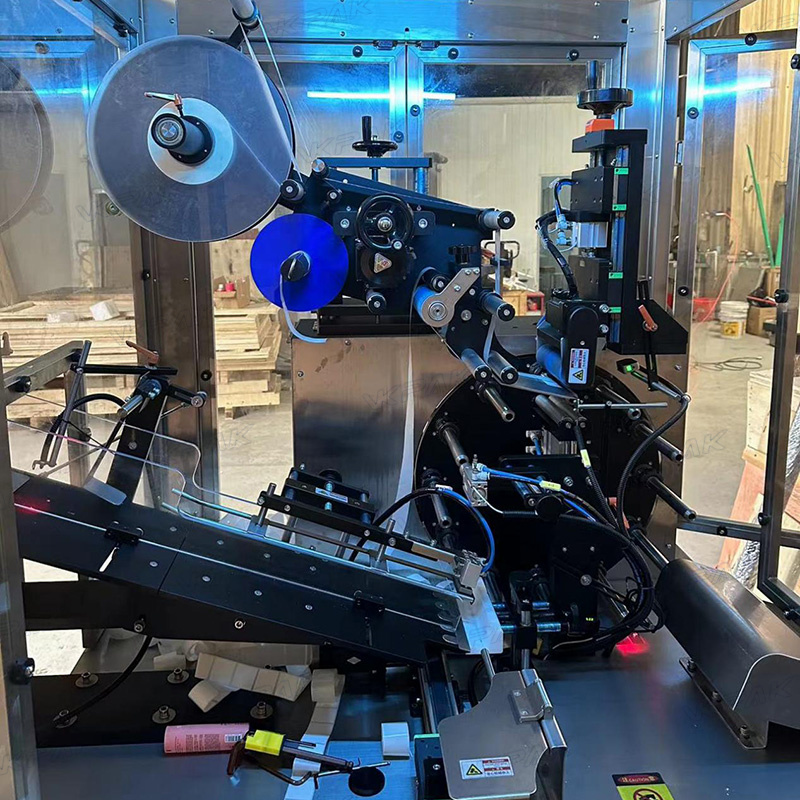

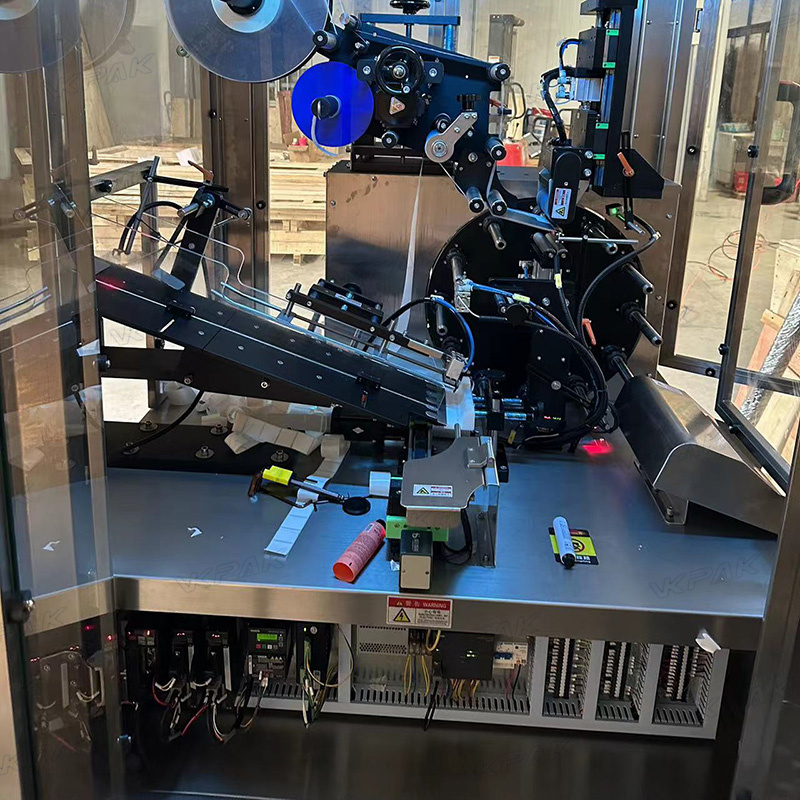

This machine is specially designed for wrap-around labeling on empty squeeze tubes, also suitable for orientation labeling on tubes that have a detectable orientation mark. Due to the insufficient rigidity of the tube body and the label is usually very soft and transparent, problems such as raised label corners and wrinkled labels will occur. The machine has the characteristics of automatic feeding, precise positioning and automatic unloading, which can solve the problems faced in the packaging process and improve work efficiency at the same time.

Output Speed: 30~50 pieces/min

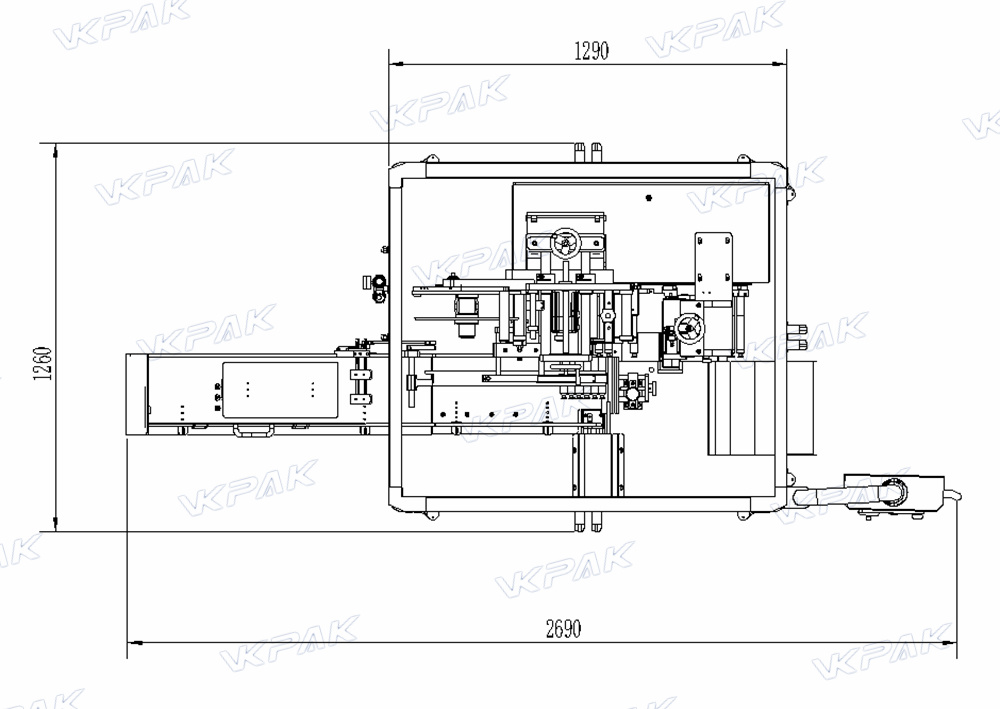

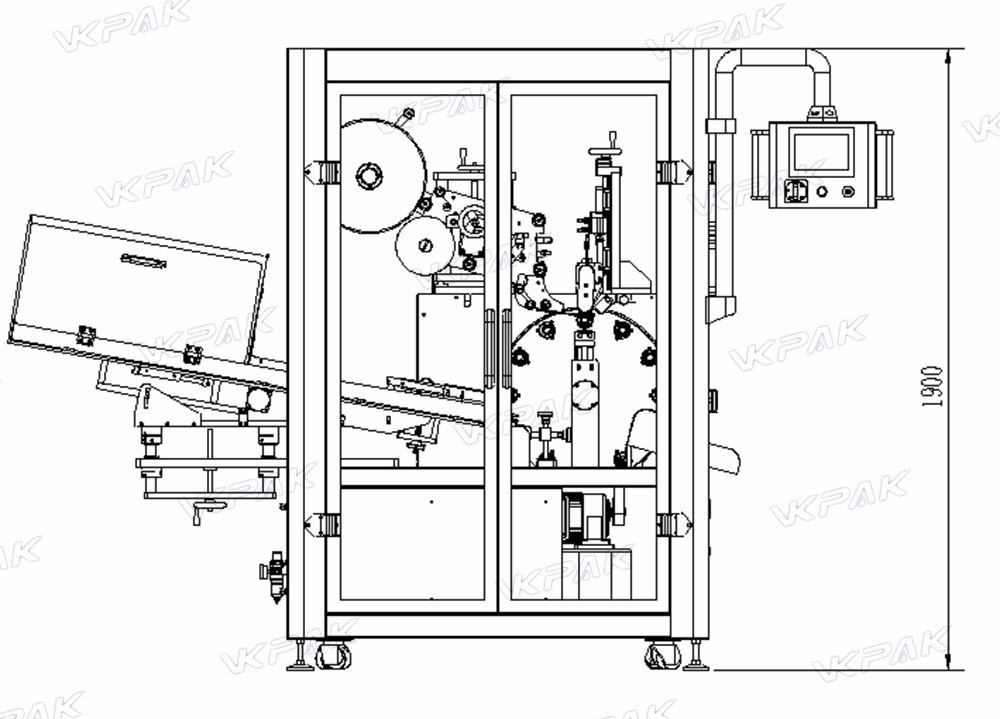

Dimension: L2500mm*W1200mm*H1800mm

View Video Download PDF

Description

High labeling accuracy, the labeling error range is about 1mm.

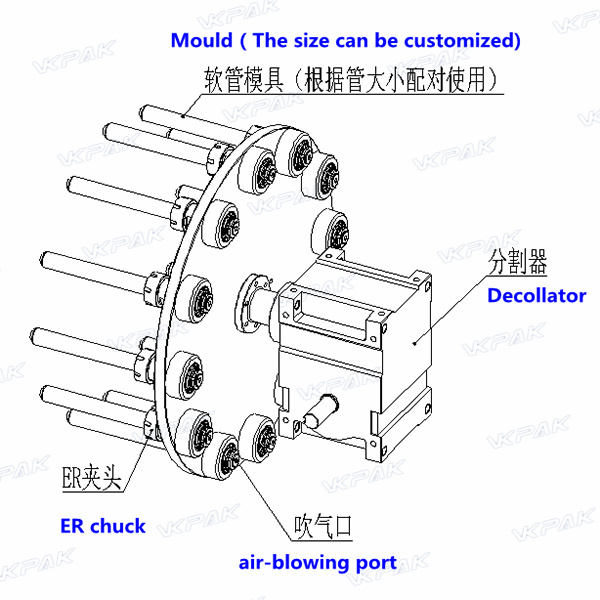

Change fixing mold can be used for other size of aluminum tube / plastic soft tube.

Can be equipped with date coder to print batch number / production date on stickers.

Can work with tube filling sealing machine to realize automated production.

Parameter

| Model | VK-STL |

| Labeling speed (pcs/hour) | 1800-2500pcs/hour (relate to material and label size) |

| Labeling accuracy(mm) | ±1.0mm (material and label sizes are not counted in) |

| Label size(mm) | (L)10-300mm (H)10-200mm |

| Material size (mm) | (diameter )φ19-50mm |

| Roll inside(mm) | φ76mm |

| Roll outer diameter(mm) | Max:Φ300mm |

| Machine size (mm) | (L)2500*(W)1200*(H)1800(mm) |

| Power supply | AC220V 50Hz/60Hz 1200W |

Application

It is suitable for sticking labels on various types of adhesives, including super glue, epoxy, silicone sealants, construction adhesives, oil paints, watercolors, toothpaste, shaving cream, hair gels, hand creams, and sunscreen lotions.

Main Feature

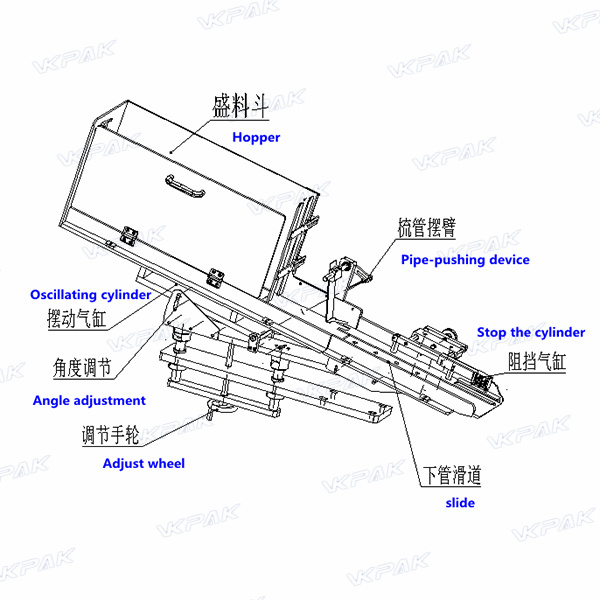

It has advantages of automatic feeding , fix position, labeling , and automatic unloading.

Equipped with high precision cam indexing drive, which is reliable, maintenance free, and precise position of tubes.

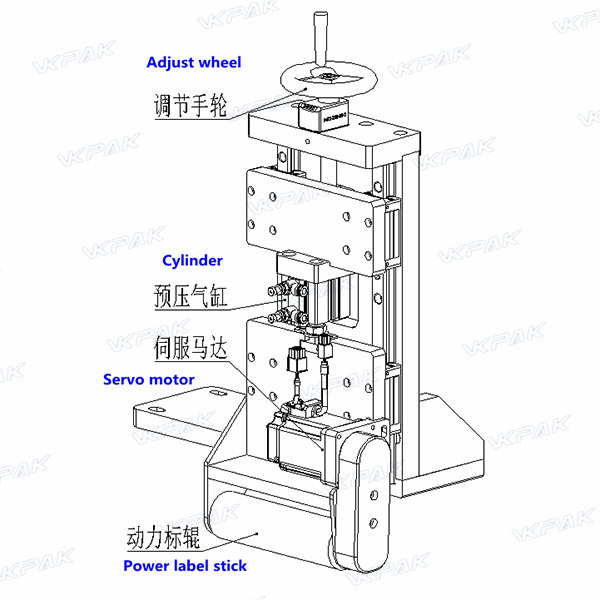

Label adapting roll is made of high quality material, the pressure can be adjusted precisely, this ensures firm label adaptation and eliminate air bubbles effectively

Can be customized for plastic soft tube

Equipped with PLC touch screen control panel, the visual working data simplify the machine debugging. Rotatable control panel improves user experience. Different kinds of operation language can be customized as operation need.

Put empty soft tube into tube feeding structure, it will make tube be in order and supply them in time, with this structure, it saves working labor.

Soft tube will be rotated and stickers will be separated and sticking to the tube, the roller will press sticker during this process, ensure there is no bubble under stickers. There is an electric eye, which can be used to detecting tube and control the machine to start labeling work.

The fixing mold for sleeving soft tube can be customized according to tube sizes, changing the mold can be used for different size of tubes.This ensures the labeling accuracy.

Machine Options:

Install ribbon coder/laser coding/Jet ink coding/TTO

Transparent label detection sensor

Add barcode detection, with or without label detection, and remaining label alarm function.

You must be logged in to post a review.

Reviews

There are no reviews yet.