VK-T803 Semi Automatic Labeler Top Labeling With Roller

$2,300.00

Tax included. Shipping calculated at checkout.

The semi-automatic labeler is a roller style labeling machine designed for labeling a variety of flat and arc surfaces. It applies a label to an uneven surface simply by changing the smoothing device. With the use of different jigs, the semi-automatic labeler applies labels to irregular shaped products.

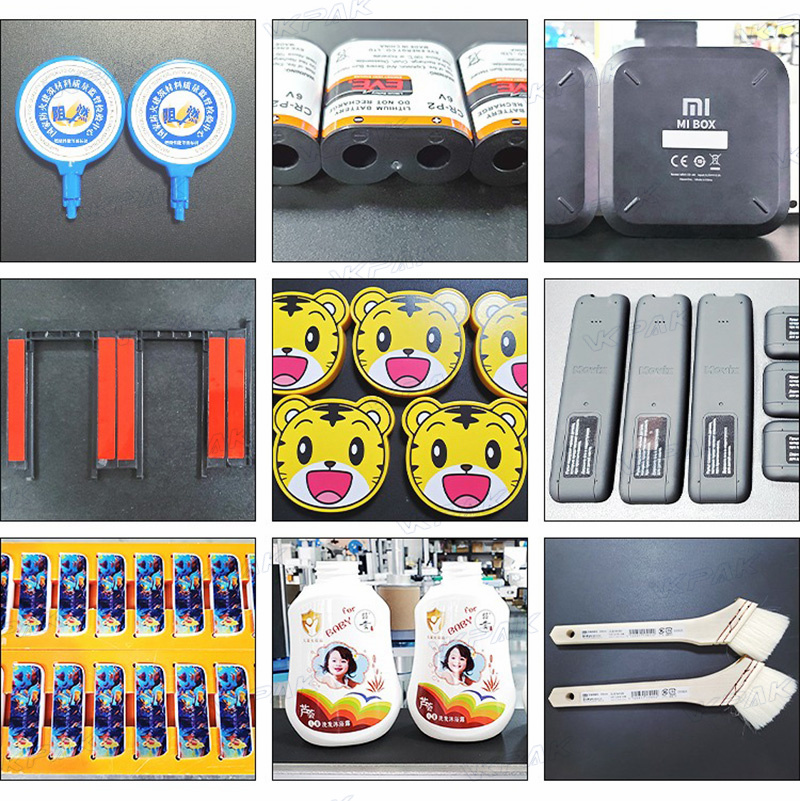

Suitable for labeling on the top plane, arc surface and concave surface of products, labeling accuracy is up to + 0.5mm, mainly used for precision labeling of electronic and digital products, such as toys, SD card, mobile phone battery, FPC, mobile phone charger labeling, etc. High precision labeling manifestexcellent quality product and greatly improve products competitiveness.

A ribbon printer and industrial inkjet printer are optional. They are used to print the production date and batch number on the label so as to realize an integration of labeling and printing applications.

View Video Download PDF

Description

| Technical Parameters | The following are the technical parameters of the standard model, if have other specicl requirements and functions can be customized |

| Labeling Accuracy | ±0.5mm |

| Labeling Speed | 15-30 pieces/min |

| Applicable for product diameter | Length: 20mm-120mm, width: 20mm-180mm, Thickness: 0.2mm-75mm |

| Applicable Label Size | Length: 15mm-300mm, Bottom paper width: 25mm~155mm |

| Device Dimensions | 995mm*432mm*966mm |

| Applicable Power Supply | 220V/50HZ |

| Weight | 58KG |

| Applicable Label Roll lnner Diameter | 76mm |

| Applicable label Roll lnner Diameter | 280mm |

The standard machine comes with one set of molds, additional molds cost $60 each.

Using the principle of roller rolling back and forth, it realizes labeling on the flat surface of the product. Suitable for toys, cosmetics, electronic accessories, cards and other products. This labeling method can ensure that there are no bubbles under the label and improve the labeling quality.

Main Feature

- The fixing molds will be customized according to labeling object, the labeling error can reduce to ±0.5mm

- Can be customized for transparent labels

- Can be equipped with date coding machine.

- Electric control system composed of PLC + subdivision stepping motor + optical fiber sensor, it works stably

The semi-automatic labeler is a roller style labeling machine designed for labeling a variety of flat and arc surfaces. It applies a label to an uneven surface simply by changing the smoothing device. With the use of different jigs, the semi-automatic labeler applies labels to irregular shaped products.

A ribbon printer and industrial inkjet printer are optional. They are used to print the production date and batch number on the label so as to realize an integration of labeling and printing applications.

Applications

Applicable labels: self-adhesive label, self-adhesive film, electronic supervision codes, bar codes

Applicable products: products requiring a label on a flat, cambered, round, concave and convex surface.

Applicable industries: cosmetics, food, toys, daily chemicals, electronics, pharmaceutical

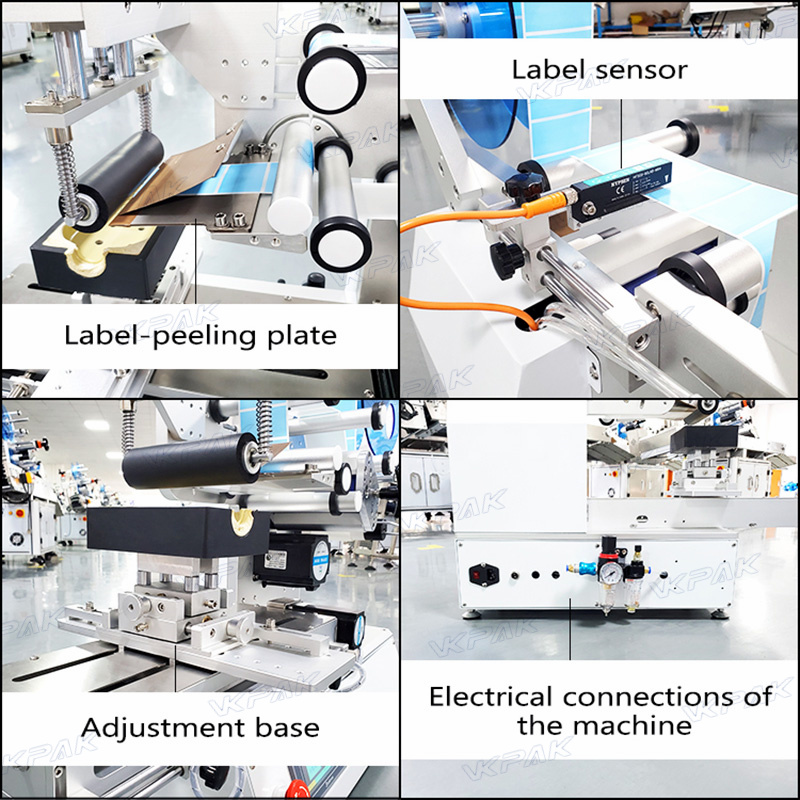

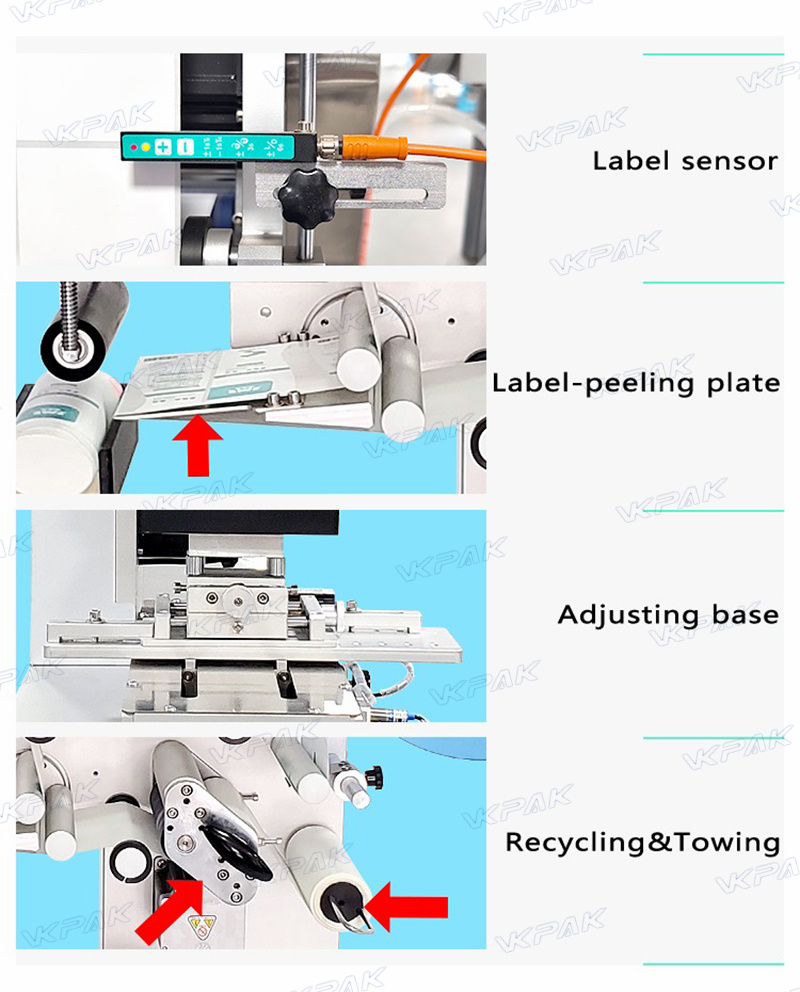

Photoelectric sensor

The labeling system is equipped with a photoelectric sensor provided by Sick, and features an exceptional precision and reliability.

Touch screen:

The touch screen is PLC controlled with an easy to use human to machine interface. With just a tap of the screen, users can easily set parameters or carry out a variety of functions.

Coding machine:

The coding machine prints information such as batch numbers on the label during the labeling process.

Smoothing device and feeding system:

The smooth device is equipped with a roller to eliminate the bubbles. The manual feeding system is efficient and convenient to use.

You must be logged in to post a review.

Reviews

There are no reviews yet.