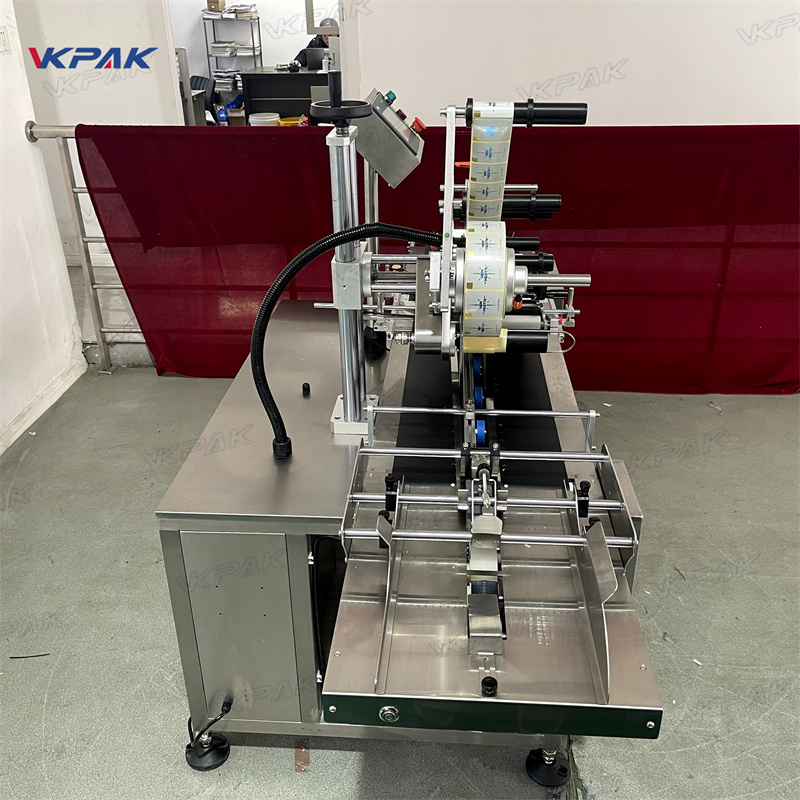

VK-TBL-F Automatic Mylar Bag Pouch Top And Bottom Labeling Machine With Friction Feeder

$8,300.00

Tax included. Shipping calculated at checkout.

This labeling machine is equipped with a friction feeder based on VK-TBL, which greatly improves efficiency. VK-TBL-F Top and bottom label applicator to apply labels on both sides of flat surfaces such as pouches or packages featuring a loading platform and high friction belting.

Output Speed: 30-60 pieces/minute depends on label and product size

Dimension: (L)2600*(W)800*(H)1500(mm)

View Video

Description

This labeling machine is equipped with a friction feeder based on VK-TBL, which greatly improves efficiency. VK-TBL-F Top and bottom label applicator to apply labels on both sides of flat surfaces such as pouches or packages featuring a loading platform and high friction belting.

Details

VK-TBL-F Touch Screen

The touchscreen interface provides a user-friendly way to operate and configure the labeling machine. It allows for quick adjustments of settings, monitoring of the labeling process, and troubleshooting. The intuitive design and integration with Siemens technology ensure reliability and ease of use, enhancing operator efficiency.

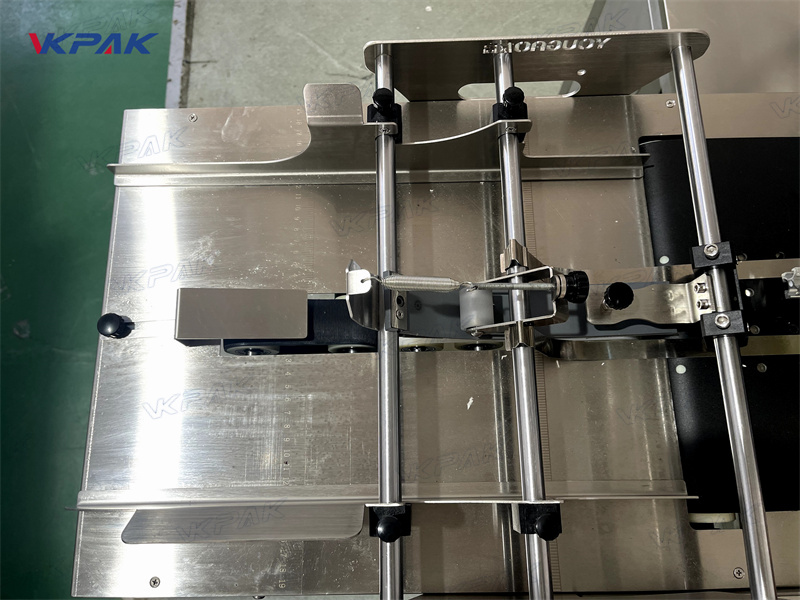

VK-TBL-F Friction Paging Machine

This component is designed to separate and feed flat products like sheets or cards for the labeling process. Its purpose is to ensure precise, high-speed handling of individual items from a stack. The advantages are increased operational efficiency, reduction of manual labor, and compatibility with various product sizes and thicknesses.

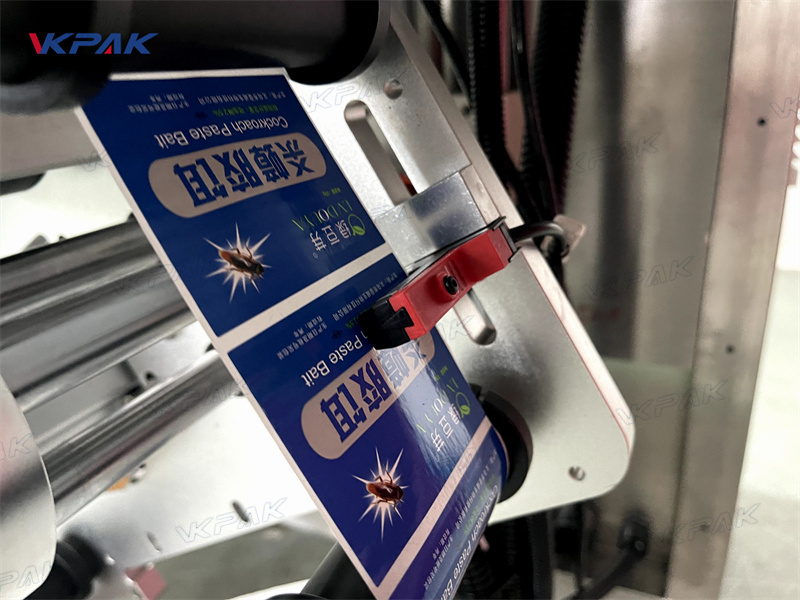

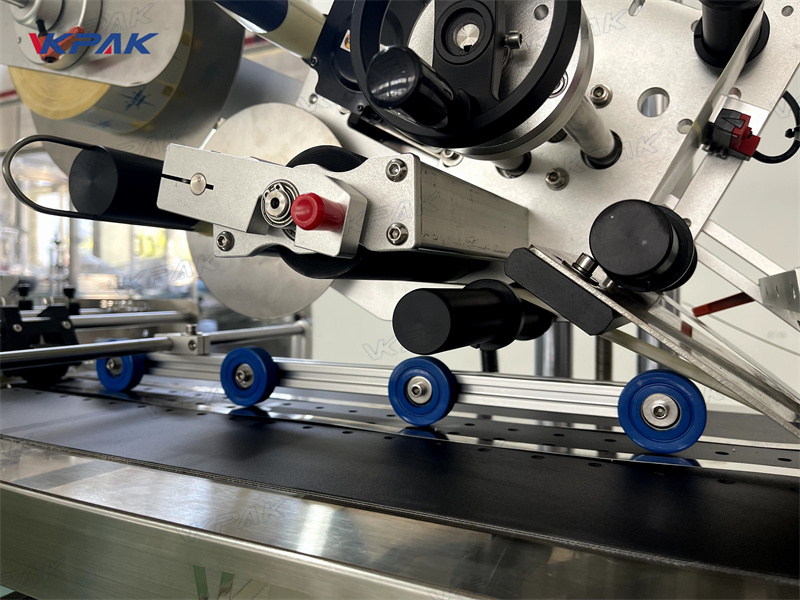

VK-TBL-F Upper Labeling Head

The upper labeling head is designed for the application of labels to the top surfaces of products. Its adjustable design accommodates different product sizes and shapes, while the robust construction ensures consistent label application. This component is integral to achieving versatility and high-quality results in various labeling scenarios.

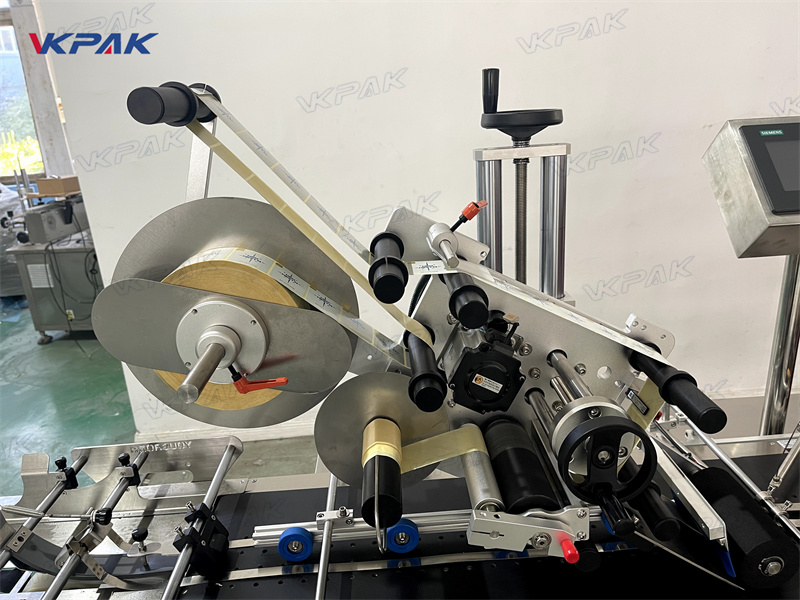

VK-TBL-F Lower Labeling Head

The lower labeling head, which holds and guides the label roll during the application process. Its ergonomic design allows for easy adjustment and alignment, ensuring compatibility with various label sizes and types. This flexibility enhances the versatility of the labeling machine and streamlines operations.

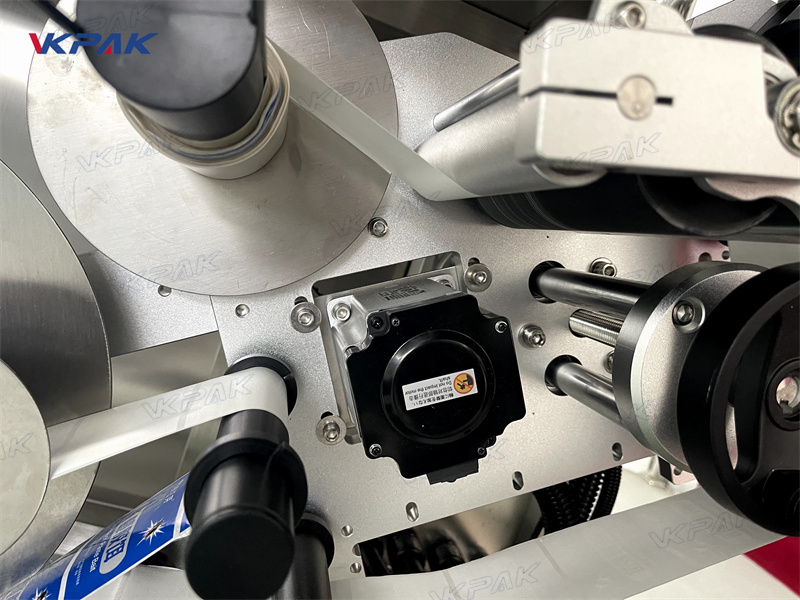

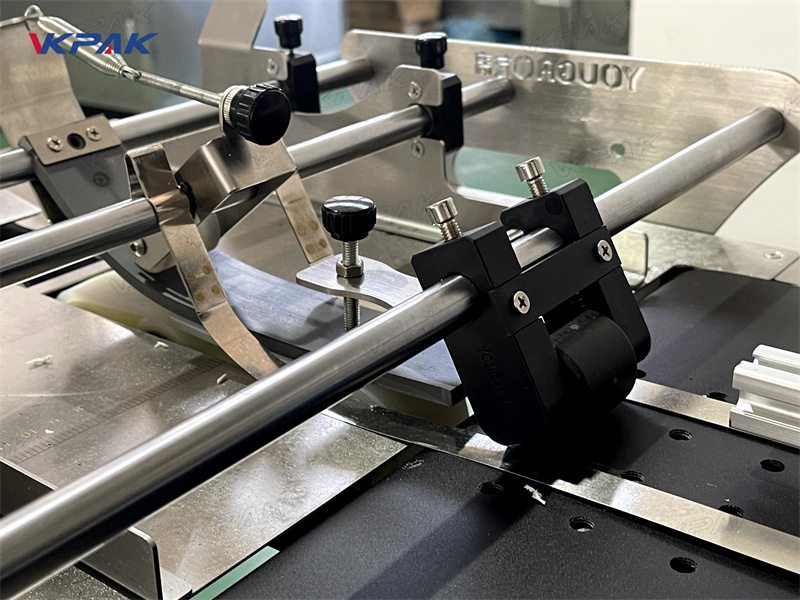

VK-TBL-F Servo Motor

The servo motor is a crucial component responsible for precise control of the labeling process. It ensures accurate positioning and smooth operation, reducing errors and enhancing the overall labeling quality. Its high torque and precision make it suitable for handling various labeling tasks at high speeds.

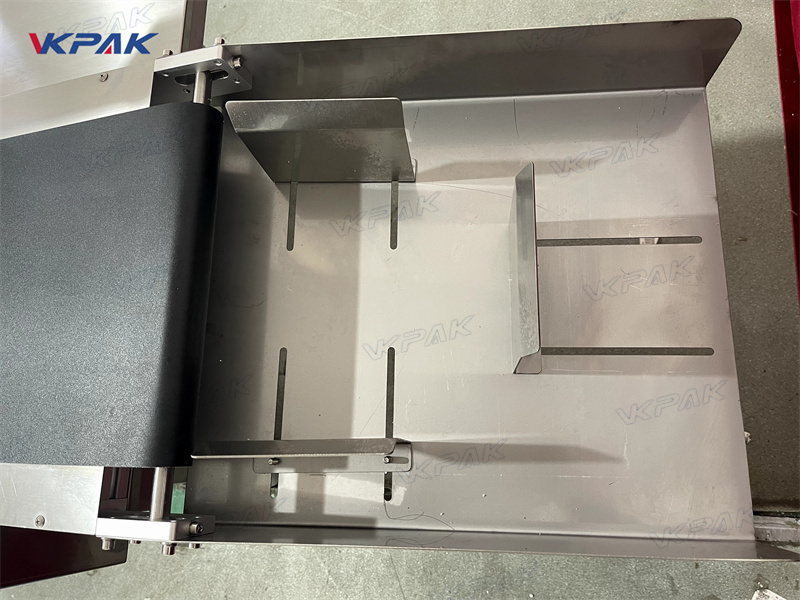

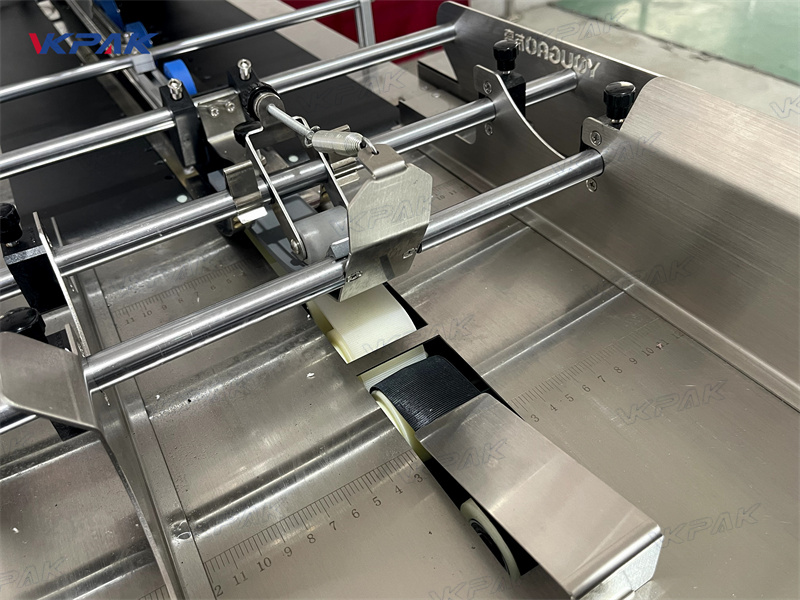

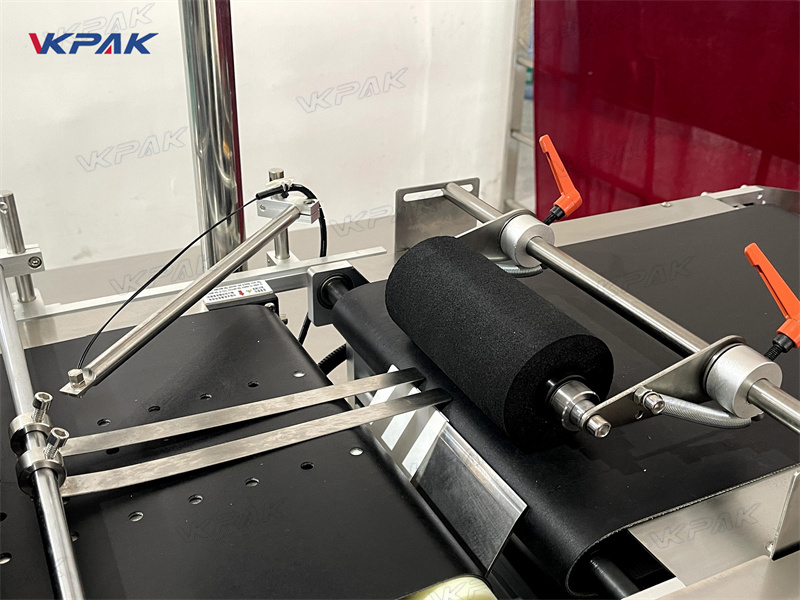

VK-TBL-F Collection Table

Collection table purpose is to collect labeled products after labeling, ensuring orderly and efficient handling. The design includes adjustable slots and barriers, which help accommodate various product sizes and maintain alignment. Its stainless steel construction ensures durability, resistance to corrosion, and easy cleaning, making it suitable for industrial applications.

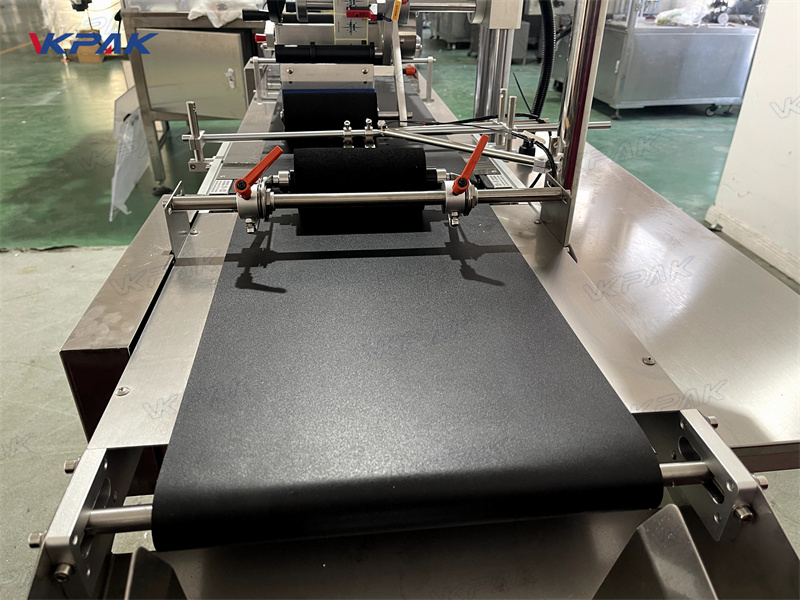

VK-TBL-F Conveyor Belt

The conveyor belt is a crucial component for transferring items smoothly during the labeling process. Its purpose is to ensure a steady and uniform movement of products, which is essential for accurate and consistent labeling. The advantage of such a design includes durability, low maintenance, and precision in aligning products for the next stage.

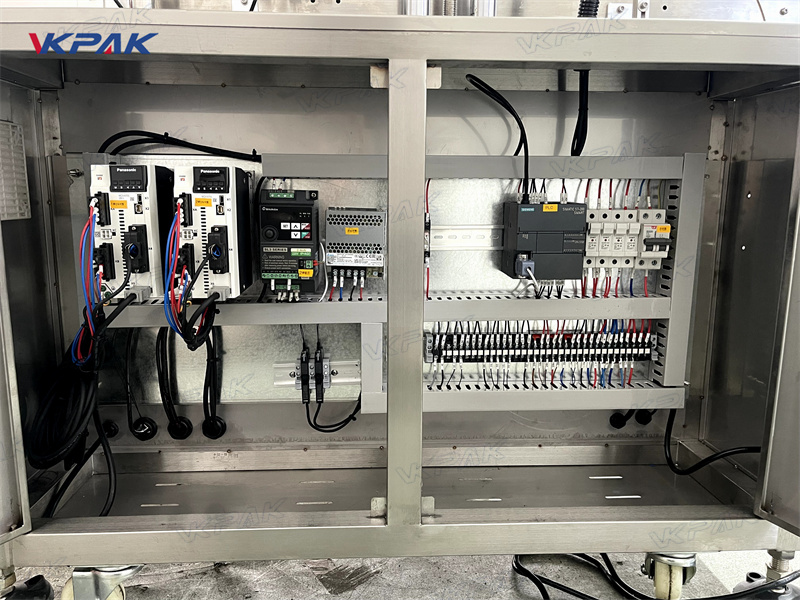

VK-TBL-F Electrical Cabinet

This cabinet houses the control and electrical components necessary for the machine’s operation, such as programmable logic controllers (PLCs) and power supplies. Its purpose is to centralize and protect the machine’s control systems. The advantages include ease of maintenance, organized wiring for troubleshooting, and safe operation by shielding sensitive components from external damage or contamination.

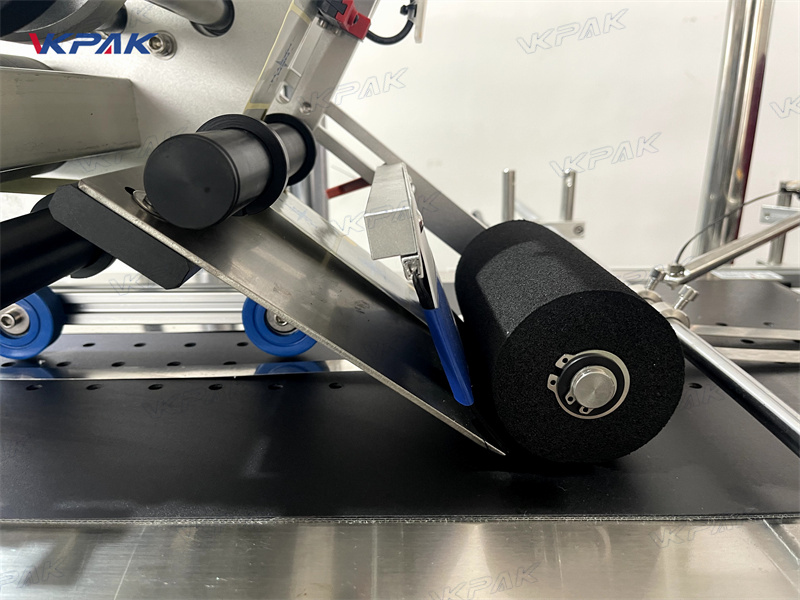

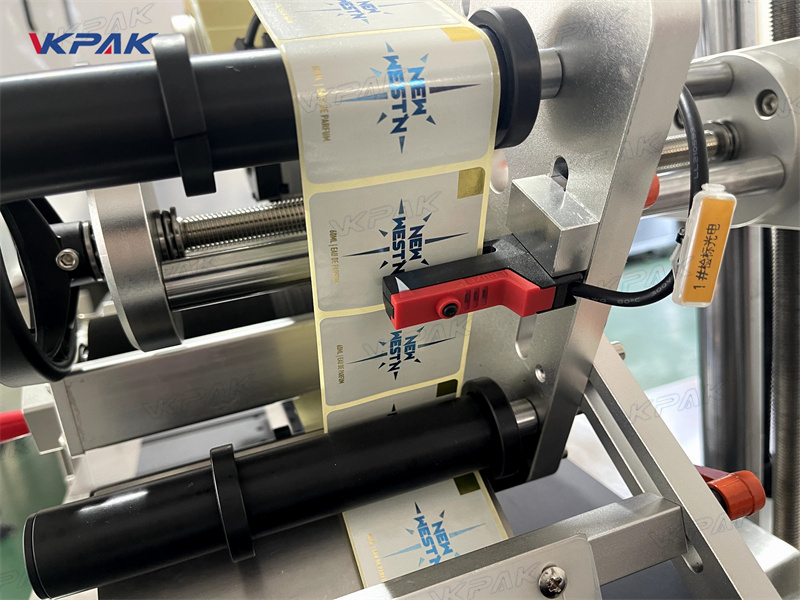

VK-TBL-F Label Peeling Knife

This label peeling knife is designed to separate the label from its backing paper, ensuring precise application to the target product. Its angled design and smooth surface help improve peeling efficiency and reduce tearing or label misalignment, contributing to higher labeling accuracy and operational consistency.

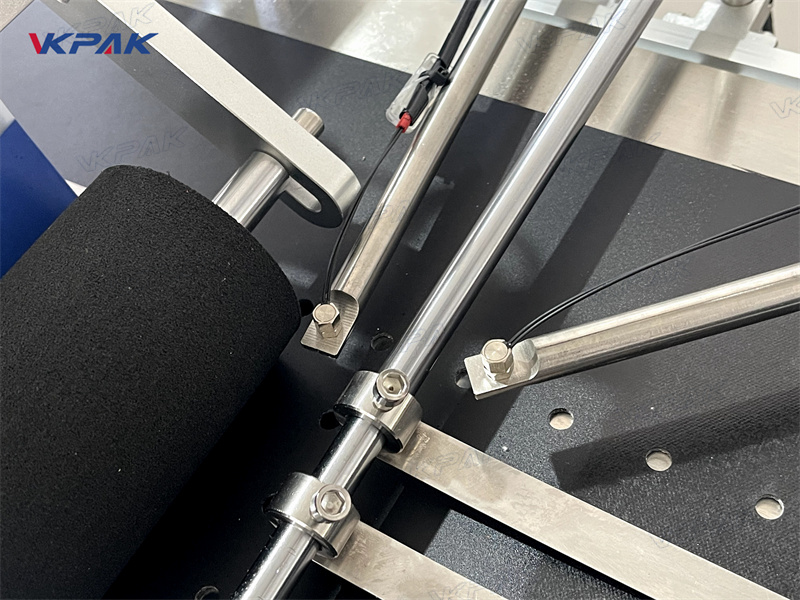

VK-TBL-F Label Sensor

This label sensor detects the labels’ position on the roll to control when and where the label is dispensed. It ensures that each label is applied correctly and consistently, improving efficiency and reducing wastage caused by misapplied labels.

Features

Touch screen control panel make the parameter visual, easier to adjust and test the machine. Help you improve labeling accuracy.

Designed for flat surface, it can be used to label stickers or film on front and back side on your products like laundry detergent bottles, helps you improve working efficiency.

The sensitivity of the label sensor can be adjusted by the machine components, this can ensure the labeling accuracy for different labeling objects.

High quality machine components, ensure the label can be pulled flat during working, make it can work for a longer time.

Equipped with conveyor, this machine can transfer labeling objects stably and quickly, improve labeling speed and labeling quality.

You must be logged in to post a review.

Reviews

There are no reviews yet.