VK-TFS-006U Semi Automatic Ultrasonic Paste Plastic Tube Filling And Sealing Machine

$8,600.00

Tax included. Shipping calculated at checkout.

This is a tube filling and sealing machine. Users need to place the tubes and it will automatically proceed filling and sealing process. The sealing uses ultrasonic technology, bringing a perfect sealing effect.

Sealing Method: Ultrasonic Sealing

Output Speed: 18-22 tubes/min

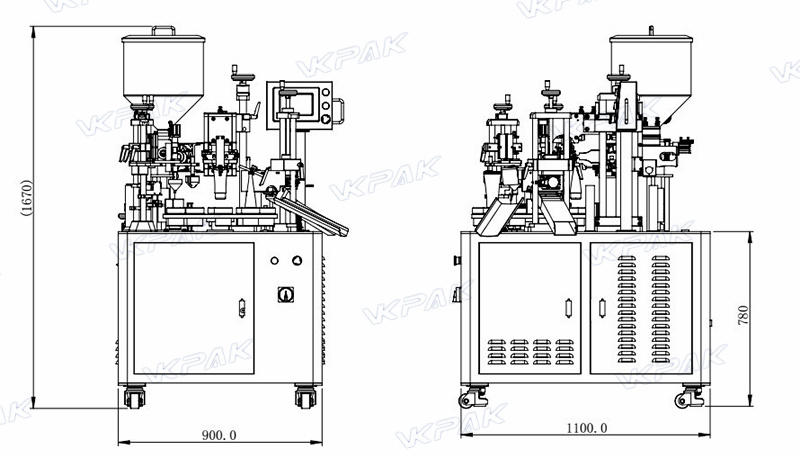

Dimension: L1300*W900*H1550

View Video Download PDF

Description

The VK-TFS-006U is linked with ultrasonic sealing, the heat required for melting is only generated inside the thermoplastic sealing layer. For localized conversion of vibrations to friction heat, the anvil or sonotrode profiles are mostly linear and include radii or small plateaus. These profiles ensure focusing of the energy input and therefore short sealing times between 100 and 200 milliseconds. With ultrasonic sealing heat is generated at the inside of the film, not by heat input from the outside as is the case with heat sealing, for example. The tools (sonotrode and anvil) that come into direct contact with the packaging material, remain cold during the entire weld process. The support layer remains almost cold and upon termination of energy input, the heat dissipates faster to the outside due to the temperature difference between the support layer and the sealing layer so that the hot-tack resistance is significantly higher.

Parameter

| Model | VK-TFS-006U |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Filling Range | A:6-60ml B:10-120ml C:25-250ml D:50-500ml |

| Filling Accuracy | 1% |

| Capacity | 18-22 tubes/min |

| Sealing Dia. | 10-50mm (Custom-made available) |

| Tube Height | 70-210mm |

| AirPressure | 0.6MPa |

| Air Consumption | 0.35m3/min |

| Dimension | L1300*W900*H1550 |

| N.W | 350kgs |

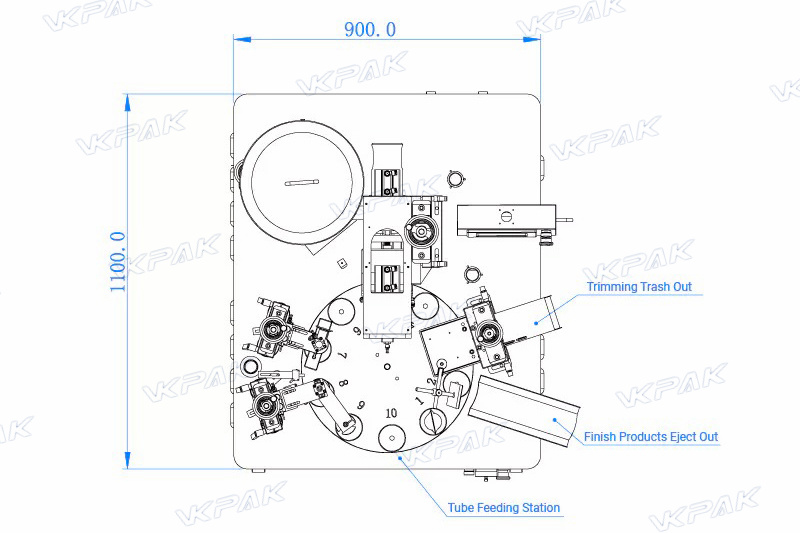

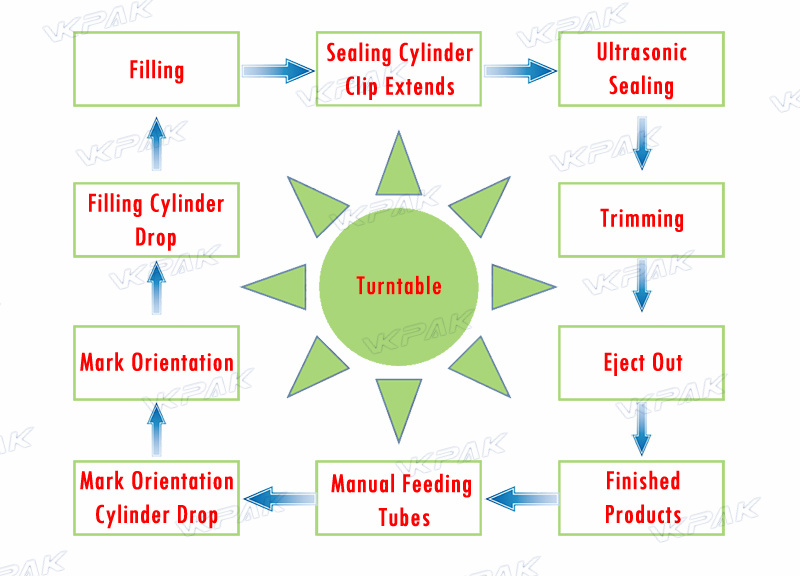

Working Process

Manually tube loading one by one

Color mark orientation and tube detecting

Auto Filling

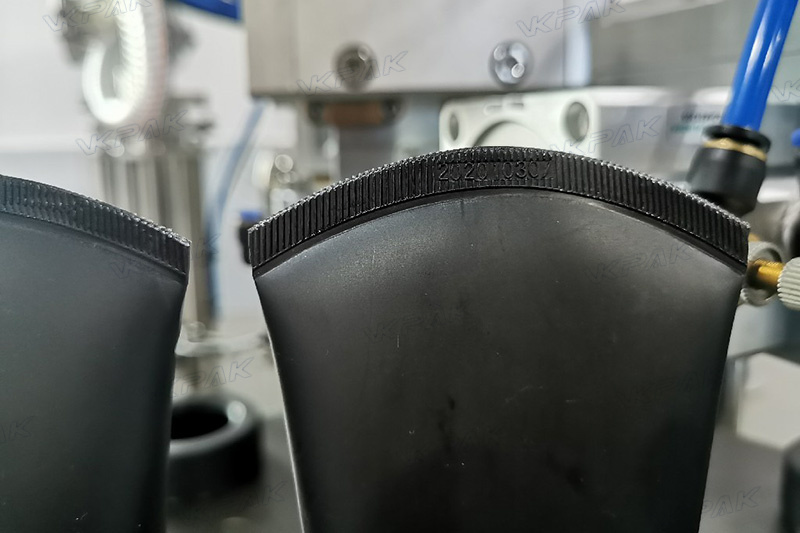

Ultrasonic sealing and date coding

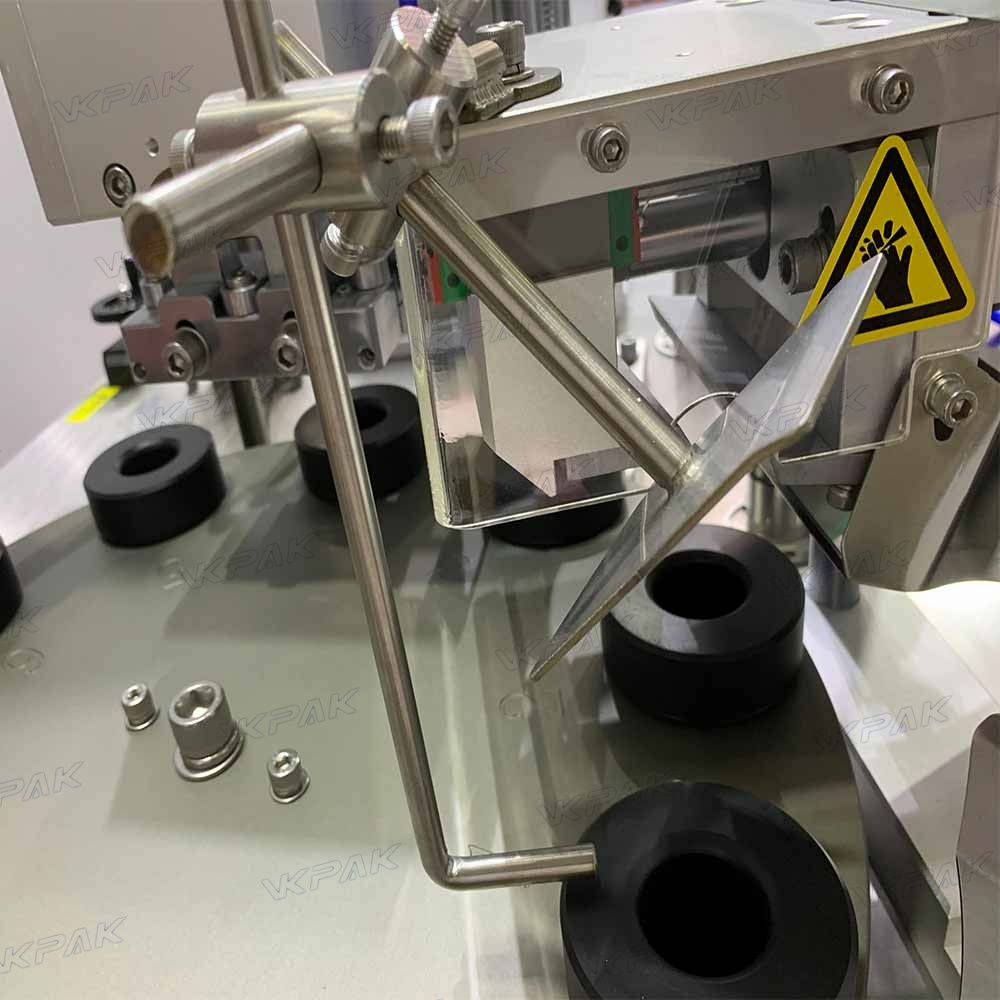

Cutting

Discharging

The control panel is designed for easy of use and intuitive operation, enabling operators to efficiently manage and control industrial process.

Ceramic pump has excellent thermal stability, good sealing performance corrosion resistance, non-magnetic and other advantages.

The automatic color code detection functio ensures that the color code position of each product is accurate. This helps to avoid incorrect filling or sealing and ensures product consistency and quality.

Ultrasonic controlled tube sealing, tightly sealed. The sealing temperature can be adjusted according to the tube material. Each workstation has a sensor to achieve automatad work.

Rotary table design, the bottom fixed mold is customized according to the size of the tube, which can perfectly adapt to the product.

Application:

This semi-automatic tube filling sealing machine can fill and seal plastic tubes and lami tubes. It is widely used in the glue, cosmetics, creams, lotion, medicine, lubricants, adhesive and shoe polish, and food industries.

Machine Options:

Auto refill pump

Heating and mixing system for material hopper

Air blow system for high viscous and sticky material

Safety door

316L stainless steel contact parts

Tube Tail Trimming Shape

You must be logged in to post a review.

Reviews

There are no reviews yet.