VK-TFS-006UDH Tabletop 2 Heads Ultrasonic Small Plastic Soft Tube Filling Sealing Machine

$10,400.00

Tax included. Shipping calculated at checkout.

This monoblock filling sealing machine can automatically fill paste into soft tube, seal soft tube at one rotary table. Ultrasonic controlled sealing structure, this ensures packaging quality and accuracy. It is suitable for packaging hand cream, lip gloss, facial cleanser.

Sealing Method: Ultrasonic Sealing

Output Speed: 40-50 pieces/min

Dimension: L1070*W830*H1310

View Video Download PDF

Description

Compact machine body saves working space.

Sealing work is controlled by ultrasonic, the machine has high packaging accuracy.

PLC touch screen control panel make machine debugging more intuitively, customizable operation interface simplifies machine operation

Extra date coder can be equipped with to print production date

Double filling heads, this machine has high working capacity, it can pack 40-50pcs/min

Suitable for the packaging small volume paste like eye gel, cosmetic cream sample, makeup primer.

Parameter

| Model | VK-TFS-006UDH |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Filling Range | 1-12ml,6-30ml,10-60ml |

| Pump | Ceramic pump (99.7%, stainless steel 304) |

| Filling Accuracy | ±0.25-0.5ml (depending on material condition) |

| Capacity | 40-50pcs/min |

| Sealing Dia. | 13-19mm (Custom-made available) |

| Tube Height | 70-210mm |

| AirPressure | 0.5MPa |

| Dimension | L1070*W830*H1310 |

| N.W | 320kgs |

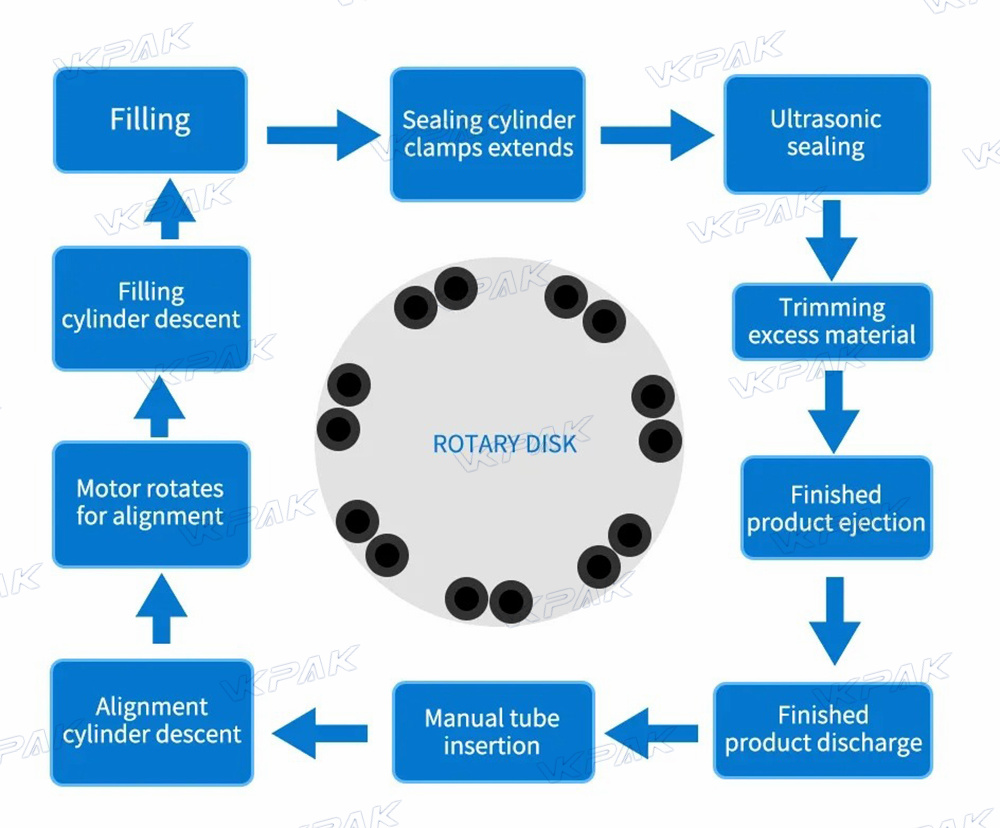

Working Process

Product Details

Equipped with PLC control panel, working data can be set more conveniently. This is can help to watch machine working status in real time. Customizable interface simplifies machine operation.

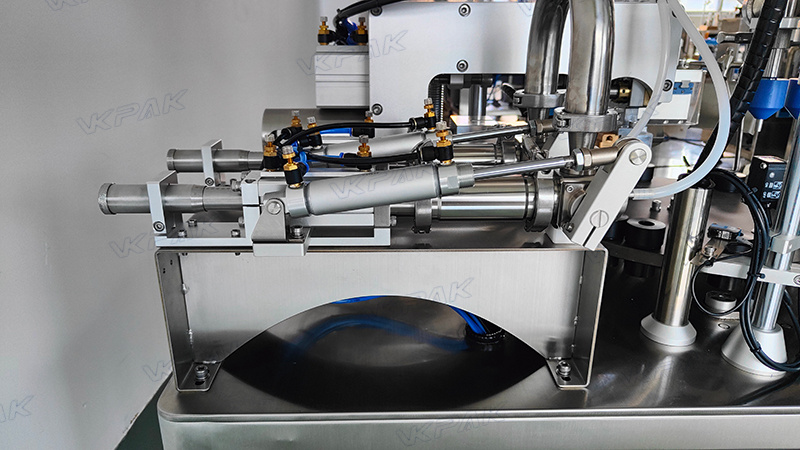

Equipped with double filling nozzles, this can improve working capacity effiectively. The working height of filling nozzle can be adjusted according to operation need. Filling work is controlled by ceramic pump, it has high filling accuracy.

Ultrasonic controlled tube sealing, this can improves sealing quality. Sealing temperature can be adjusted according to tube material. There is a sensor at each working station, it realizes automated work.

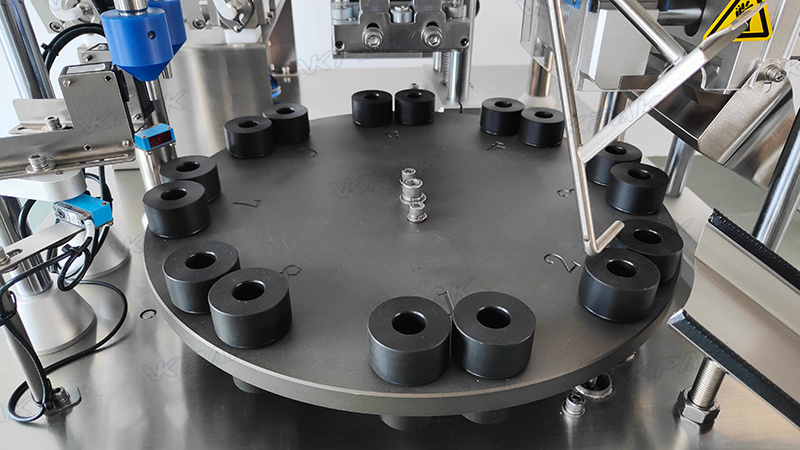

Rotary table conveyed tube to each working station,it prevent soft tubes from falling down during conveying. Bottom fixing molds are customized according to tube size.The discharge port is equipped with a shielding plate to improve the working quality of outputting finished products.

Samples

You must be logged in to post a review.

Reviews

There are no reviews yet.