VK-TFS-009H Automatic Cosmetic Plastic Laminated Soft Tube Filling And Sealing Machine

$16,800.00

Tax included. Shipping calculated at checkout.

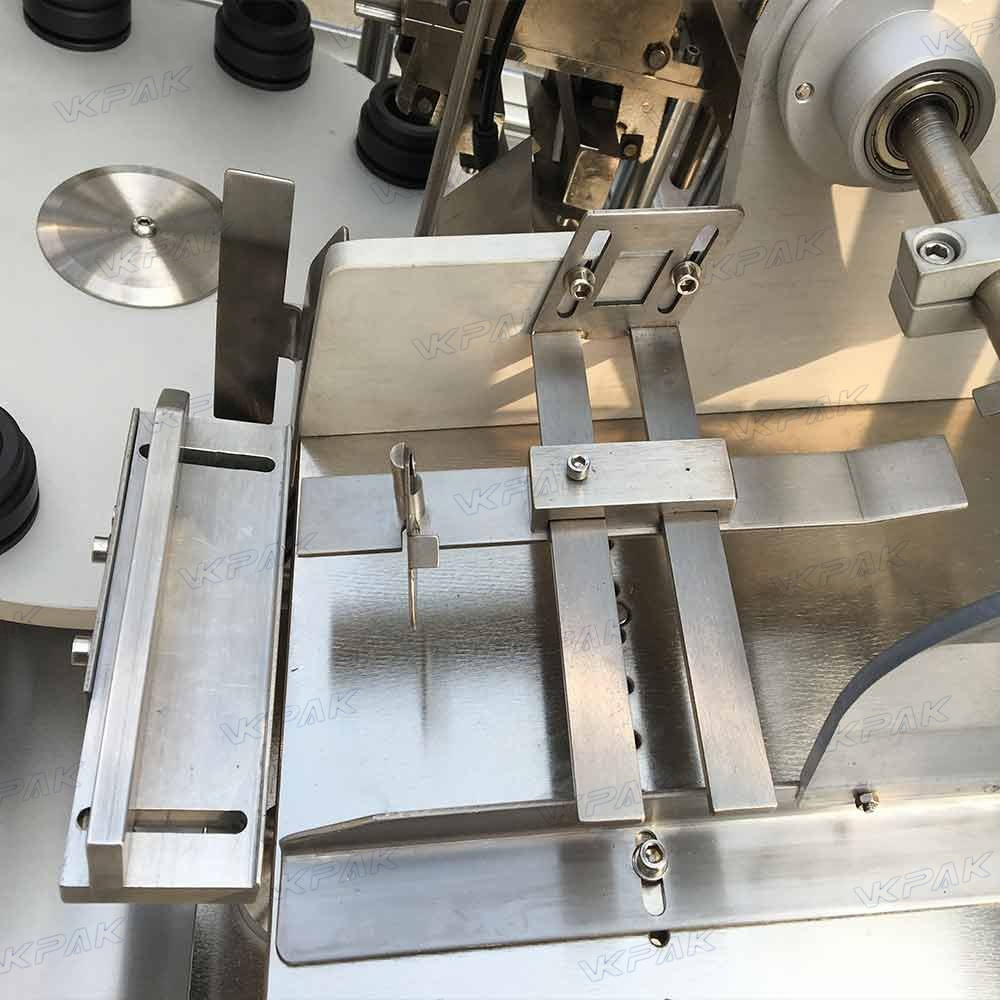

The machine adopts touch screen and PLC control. The automatic tube feeding, automatic positioning and imported rapid high-efficiency heater and highly stable flow meter form the hot air heating system. It has such features as firm sealing, high speed,no damage to the surface at the sealing place, beautiful and neat sealing shape. The machine can be equipped with filling heads of different specifications to meet the filling requirements of different viscosity. The organic glass dust cover is also provided.

Sealing Method: Hot Air Sealing

Output Speed: 30-60 pieces/min

Dimension: L2500*W1200*H2400mm

View Video Download PDF

Description

This tube filling and sealing machine is widely used in pharmaceutical, cosmetic, food and chemical industries etc. It is applicable in various aluminum plastic compound soft tube, plastic soft tube.

The VK-TFS-009H automatic plastic tube filler sealer machine is designed for filling and sealing plastic tubes, composite tubes, and aluminum-plastic tubes. It boasts a production speed of 50-80 tubes per minute, a filling range of 3-500 ml per tube, and a filling accuracy of ≤±0.5%. The machine features a compact structure, compliance with pharmaceutical machinery industry standards, and components made of high-quality materials like stainless steel and 316L stainless steel. It is suitable for industries such as pharmaceuticals, food, and daily chemicals.

1. With 12 stations and matching with manipulator, the machine is able to meet different type of tail folding, sealing requirements of Alu tube. It is a multi-purpose machine.

2. Tube feeding, eye marking, tube interior cleaning (optional), material filling, sealing (tail folding), batch number printing, finished products discharging can be performed automatically (the whole procedure).

3. Servo control makes it precise and convenient to adjust the filling amount by touch screen.

4. According to the different length of the tube, height of tube chamber can be adjusted easily by motor. With external reversal feeding system, makes tube charging more convenient and tidy.

5. The mechanical linkage photo sensor precision tolerance is less than 0.2mm. The chromatic aberration scope between tube and eye mark is reduced.

6. Photo-electronic, electric, pneumatic integrative control is applied with the machine. No tube, no filling. It gives an alarm when low pressure occurs. The machine stops automatically if tube error or open the safety door.

7. Three-layer jacket instant heater with inside air heating, it won’t damage the pattern on outer wall of tube and achieves firm and beautiful sealing effect.

Technical Parameter:

| Model | VK-TFS-009H |

| Total Power | 2Kw 380V/220V 50Hz |

| Heat sealing power | 3Kw |

| Tube material | Plastic Tube, Laminate Tube |

| Tube diameter(ram) | φ10-φ60 |

| Tube length(mm) | 45-300 (customizable) |

| Filling volume | 5-500ml (Adjustable) |

| Filling accuracy | ≤±0.5% |

| Speed(r/min) | 2.5-7 |

| Product capacity(pc/min) | 30-60 (Adjustable) |

| Air supply | 0.55-0.65Mpa 0.1 m 3 /min |

| Overall dimension | 2500×1200×2400mm |

| Machine weight | 500kg |

Application:

Used in packaging in medicine, daily chemical, food, chemical, cosmetics and other industries, such as ointment, adhesive, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste and other liquid or paste-like materials filling And the sealing.

The machine adopts a fully enclosed dust cover, the machine body is made of SUS304 material, and the appearance is unique and beautiful;

The replacement of the base is suitable for filling and sealing of various specifications of pipes, the sealing appearance is neat and tidy, and the sealing is firm;

The photoelectric benchmarking workstation uses high-precision probes, stepping motors and other precise control patterns to be located in the correct position.

The filling speed and measurement accuracy are convenient and adjustable, with high adjustment accuracy and good stability;

The machine can be equipped with various filling methods of different specifications to meet the filling requirements of different viscosities;

The internal heating is heated by Leister hot air gun, and the external water-cooling device is configured to cool down to make the sealing more beautiful;

The typing station automatically prints the word code on the position required by the process;

All parts of the machine contacting materials are made of stainless steel SUS304;

Adopt PLC control system, simple operation, intuitive and convenient, complete functions, stable operation.

You must be logged in to post a review.

Reviews

There are no reviews yet.