VK-TL Automatic Tabletop Round Dropper Essential Oil Bottle Self-Adhesive Labeling Machine

$2,100.00

Tax included. Shipping calculated at checkout.

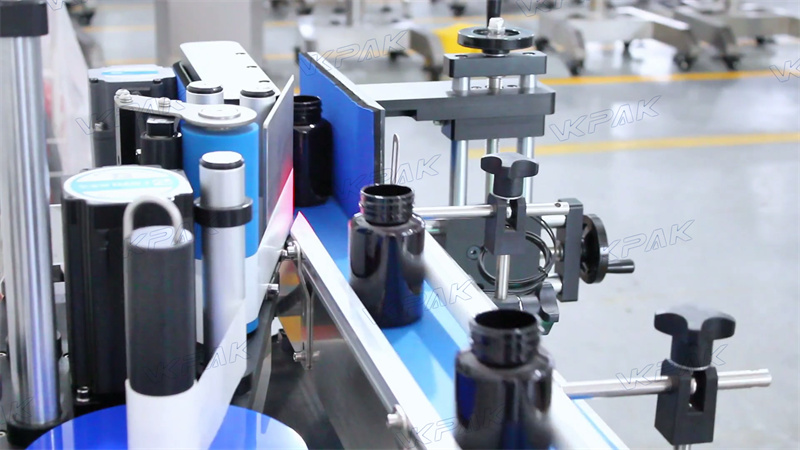

This small labeling machine is suitable for labeling self-adhesive stickers on round bottles, the labeling structure is consist of two labeling belt, the sticker will be labeled during transporting. This kind of labeling method can improve working efficiency greatly.

Can work with automatic filling and capping machine to realize automated production.

High working efficiency, it can label 20-50 bottles/min.

Output Speed: 20-50 pieces/minute depends on label and product size

Dimension: 1100(L)700(W)650(H)mm

View Video Download PDF

Description

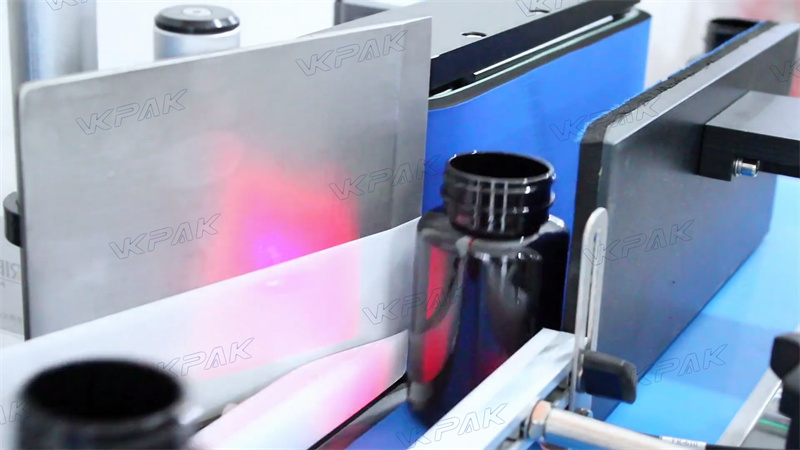

When the separated label is attached to the bottle, the machine will press the self-adhesive label tightly through the labeling belt to complete the labeling work. The labeling efficiency of this kind of labeling method will be faster, but it is not suitable for the double sides labeling on round bottle. This machine is good for packaging essential oil bottles, nail polish bottles, skin toner bottles. Extra coding function can be realized as production.

The english operation panel makes it easy to test and use the machine, the label separating speed is adjustable. And can set the delay time of label separating. The beside two knobs can control the labeling speed annd conveyor speed as your need.

The label separating plate will separate stickers and stickers will be labeled by the labeling belt during transporting. The soft labeling belt can ensure there is no bubble under stickers, improves labeling quality.

Equipped with chain conveyor, it has large weight capacity. The feeding inlet can be adjusted according to the bottle diameter. This improves working efficiency.

The electric eye is used to detect passing by bottles, it can realize the automatic work. The sensitivity of electric eye can be adjusted the small component, this can improve labeling quality.

This machine can be euipped with a date coder, whch can code batch number and production date, this can shorten the production process.

Technical Parameter:

| Model | VK-TL |

| Capacity (PCS/min) | 20-50(depend on bottle and label size) |

| Conveyor running side | from left to right / from right to left |

| Conveyor speed(meter/min) | ≤25M/MIN |

| Labeling error | < ±0.8mm |

| The inner diameter of label roll | 76 mm |

| The outer diameter of label roll | 360 mm(max) |

| Suitable for label size | W:5-300mm, L:10-500mm |

| Suitable size of labeling objects | any size |

| Power supply(In China) | AC220V 50/60HZ single phase (customized) |

| Power | 1300W |

| Weight | 100 KG |

| Machine size | 1100(L) 700 (W) 650 (H) mm |

Application:

Equipped with touch screen control panel, the customizable interface simply the machine operation, visual working data helps to watch machine working status in real time.

The label separating plate will separate stickers and stickers will be labeled by the labeling belt during transporting.The soft labeling belt can ensure there is no bubble under stickers, improves labeling quality.

Conveying speed can be adjusted according to production need easily, ensure product can be transported smoothly. The feeding inlet can be adjusted according to the bottle diameter, prevent bottles from falling down during labeling.

The electric eye is used to detect passing by bottles, it can realize the automatic work. The sensitivity of electric eye can be adjusted the small component, this can improve labeling quality.

Date coder is optional, it can be euipped with and code batch number and production date on label stickers, this can shorten the production process.

You must be logged in to post a review.

Reviews

There are no reviews yet.