VK-VRL Automatic Essential Oil Beer Cans Glass Jar Wine Round Bottle Labeling Machine

$3,500.00

Tax included. Shipping calculated at checkout.

This full automatic round bottle labeling machine is designed for single side label.It can transfer the bottle, separate stickers and label them on bottles precisely. Equipping with date printer to print production date is also available. Auto labeling machine help you improve working efficiency.

This machine is used for labeling single side stickers on round bottles.

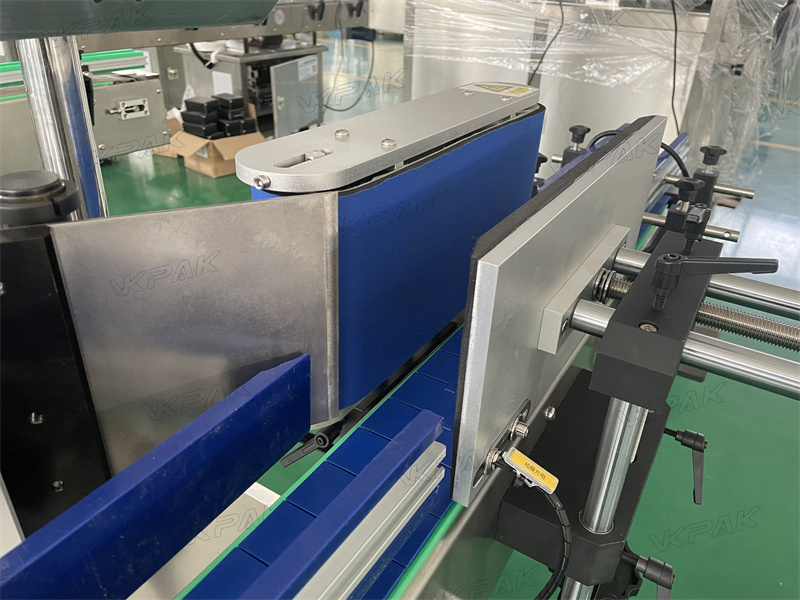

Date printer can be equipped with to realize coding function.

It can work with automatic filling and capping machine to realize automated production.

Output Speed: 20-120 pieces/minute depends on label and product size

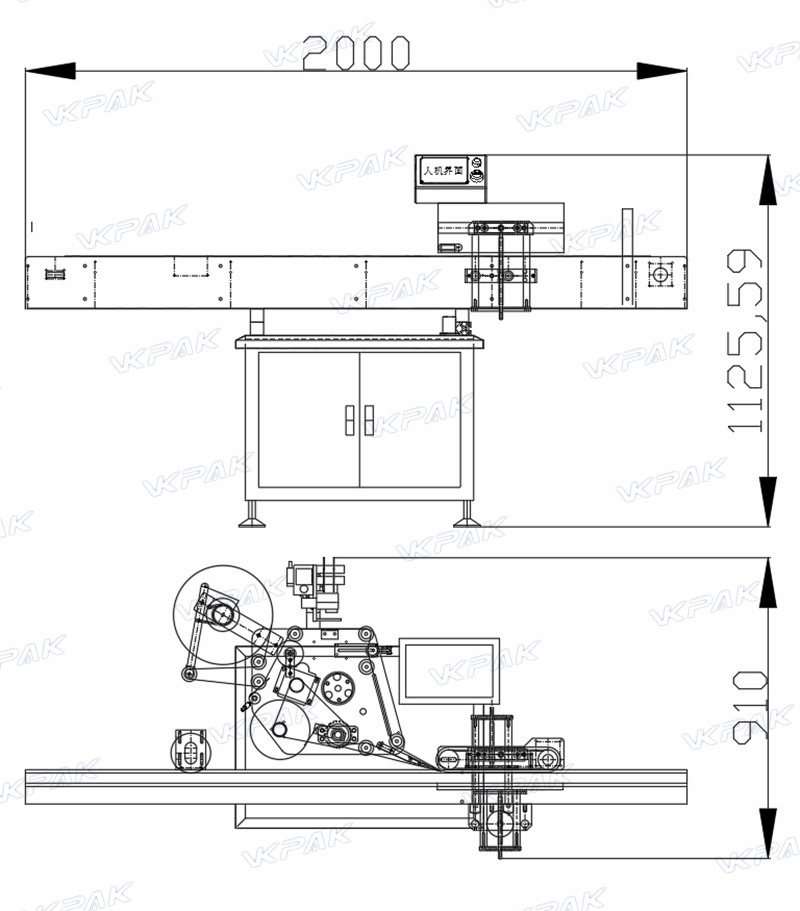

Dimension: L2000 * W800 * H1750 mm

View Video Download PDF

Description

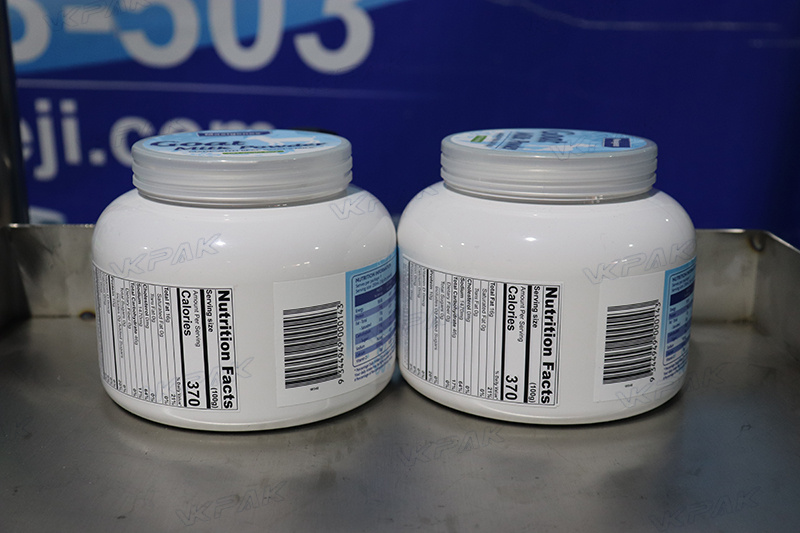

This machine has high working speed when compared with similar labeling machines, it can label 20-120 bottles/min.This labeling machine is suitable for single side labeling on round bottles like essential oil, shampoo, jam jar and can realize automated production when working with automatic filling and capping machine.It is widely used in food, daily chemical, and cosmetics industries.

This labeling machine uses the soft labeling belt to label self-adhesive stickers around bottle body during bottle transporting. It is more efficient and suitable for essential oil, shampoo, jam jar. It can work with automatic filling and capping machine to realize automated production. This machine is widely used in food, daily chemical, and cosmetics industries.

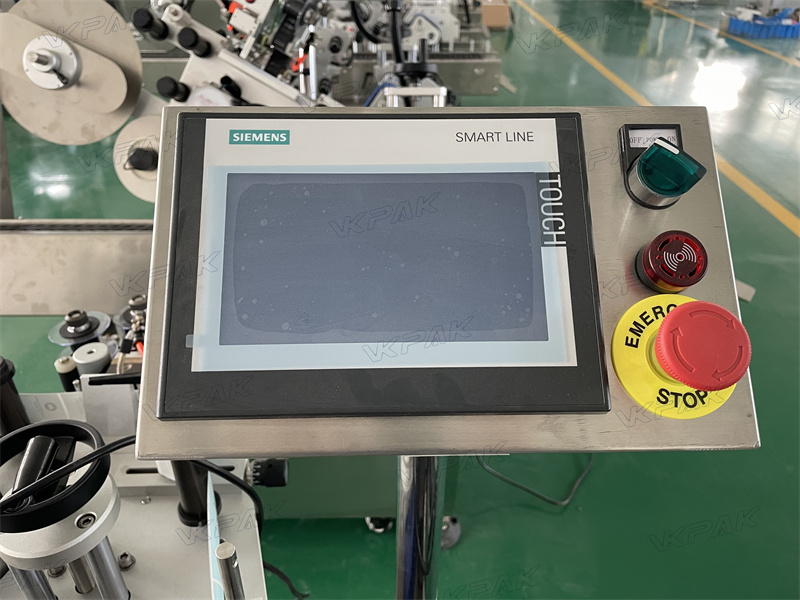

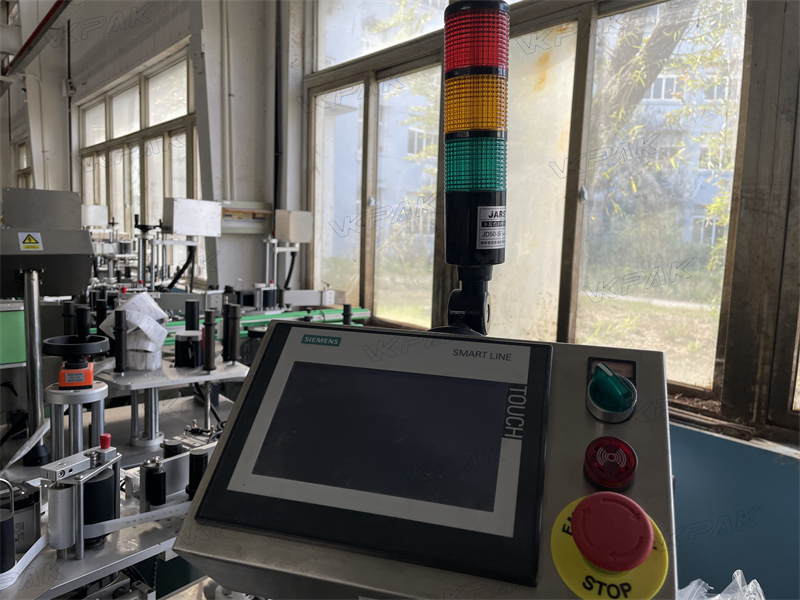

Simple operation panel can be used to adjust and control working data, easy to operate and reduce working error greatly.

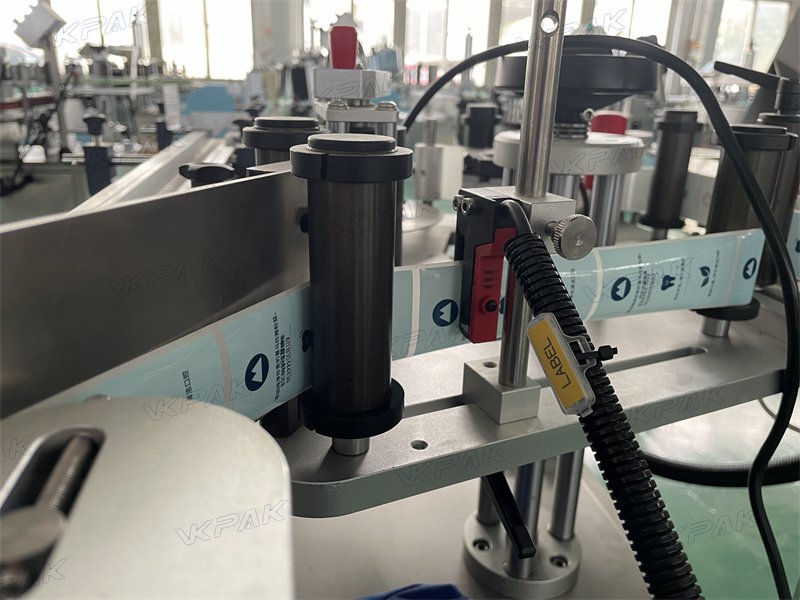

Electric eye can detect round bottles once they are transferred. It will not work unless the round bottle is detected. This prevents from missing bottles and wasting labels.

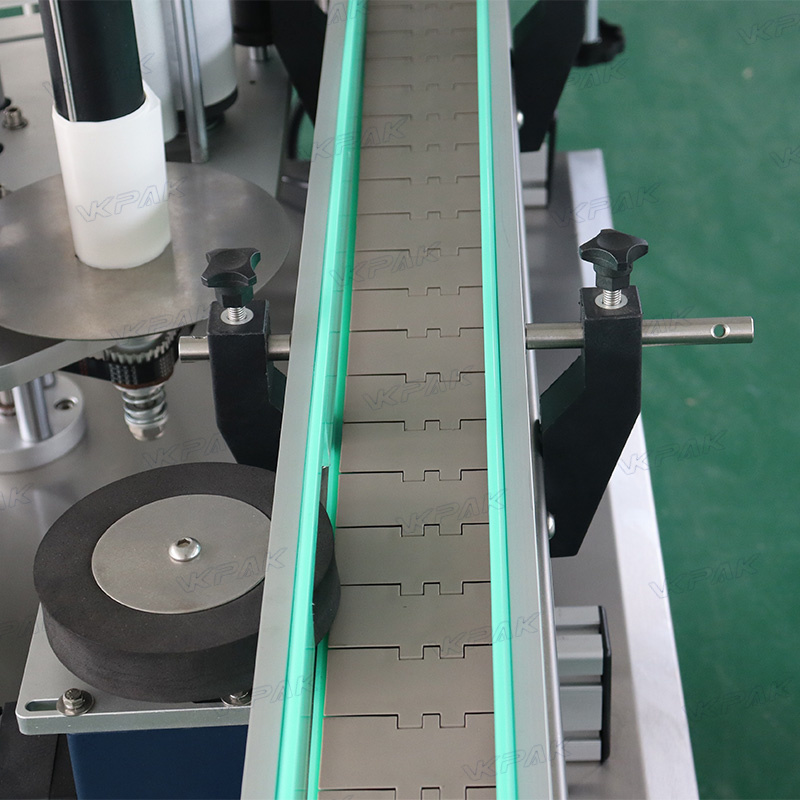

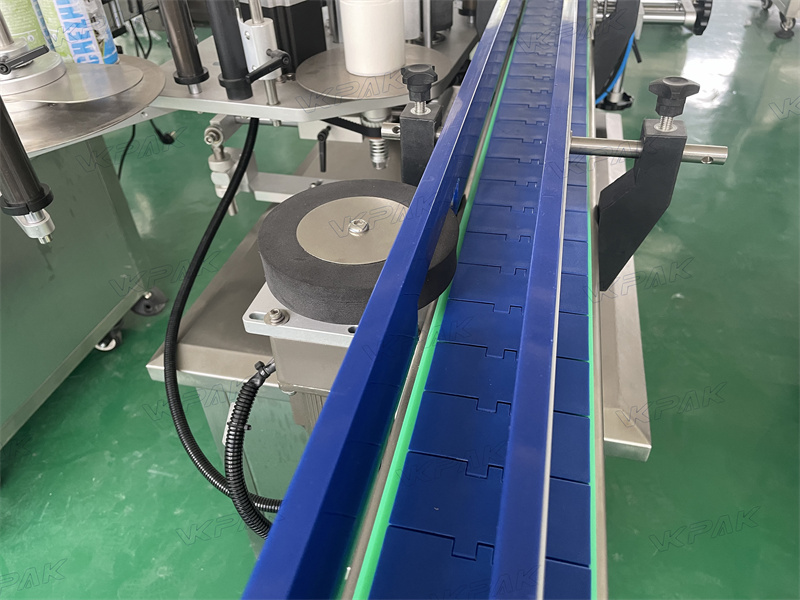

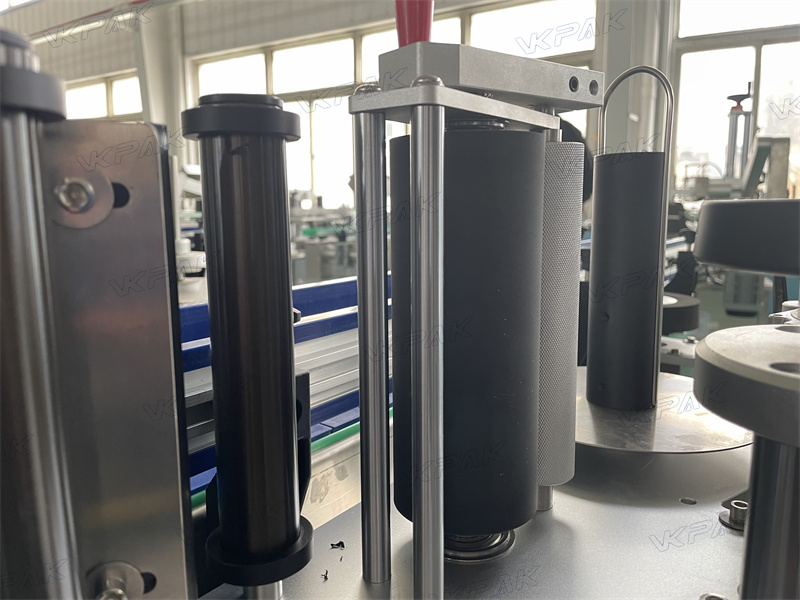

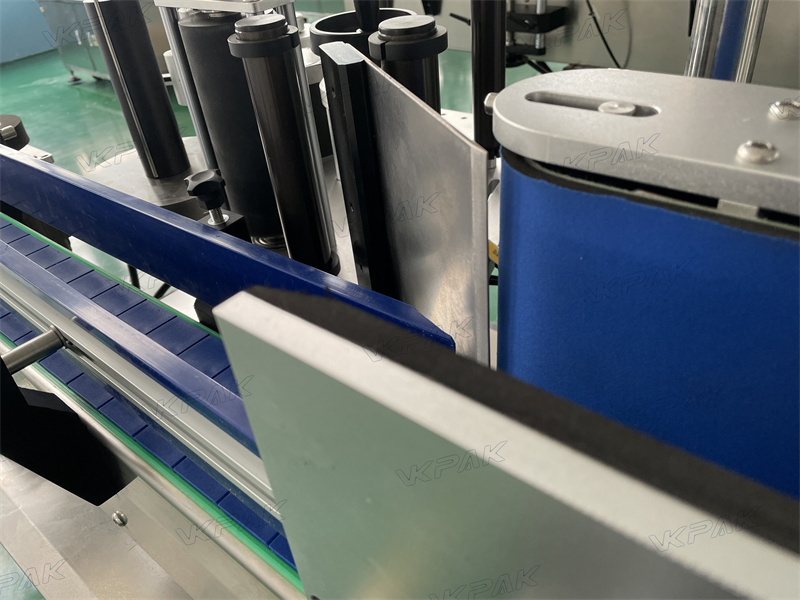

The label separating plate will separate stickers and stickers will be labeled by the labeling belt during transporting. The soft labeling belt can ensure there is no bubble under stickers, improves labeling quality.

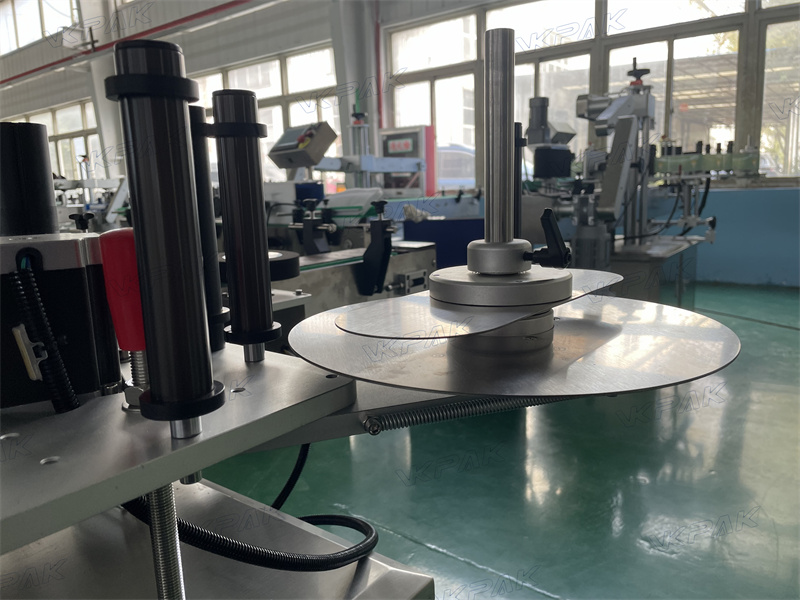

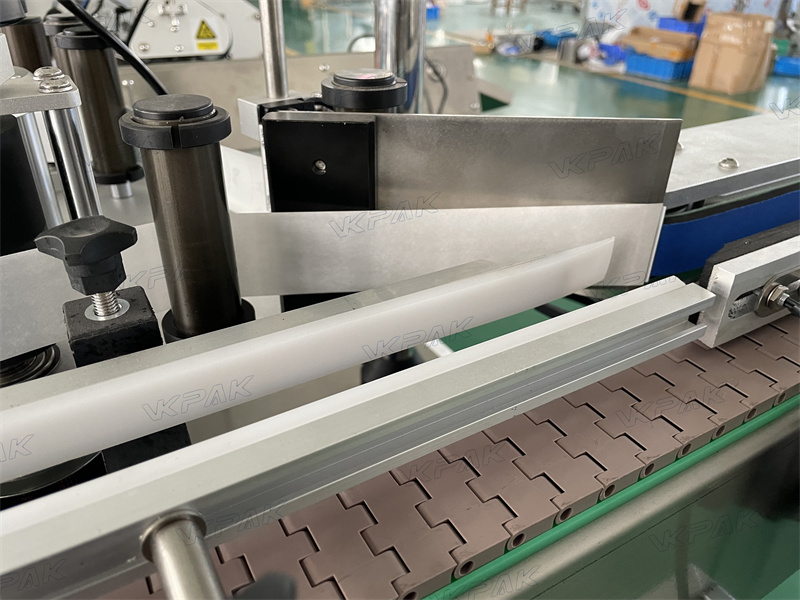

Bottle separating device can separate passing through bottles, help to control the bottle distance, reduce labeling error.

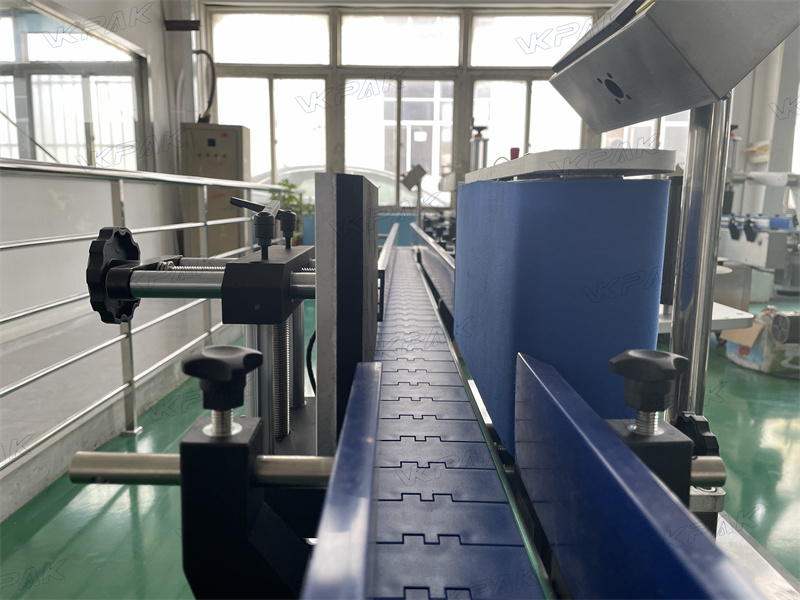

The conveyor is used to transfer round bottles. The working speed is adjustable, operator can adjust the speed according to their need. The width of feeding inlet can be adjusted according to bottle diameter.

Technical Parameter:

| Model | VK-VRL |

| Label width(height) | 10-180mm |

| Label length | 20-350mm |

| Capacity | 20 - 120 bottles/min |

| Conveyor speed | 0-30m/min |

| Labeling accuracy | ±1.0mm |

| Bottle diameter | Below 120mm |

| Power supply | 700W, 110V/220V, 50/60Hz, 1 phase (customized) |

| Label reel Inner diameter | 76mm or 40mm |

| Label reel outer diameter | Max 380mm |

| Machine size | L2000 * W800 * H1750 mm |

| Machine net weight | 250KG |

| Date printer | Optional |

| Transparent sensor | Optional |

Application:

Designed with PLC control panel, it Is easy to set or adjust working parameters like labeling length. The language of panel can be customized as your need.

This machine Is suitable for labeling single stickers on round bottles. The sponge belt can make sure that there are no bubbles under stickers, ensuring good labeling

With high quality label sensor, it can detect labels and control machine to output labels accurately. Its sensitivity can be adjusted according to production need.

With chain conveyor belt, it has large loading capacity, which can transport products stably. The conveying speed and width of conveyor belt can be adjusted as needed.

Equipped with high quality components, the machine can run stably and run for a long time. Durable and reliable.

More Samples

You must be logged in to post a review.

Reviews

There are no reviews yet.