VK-VRL-H High Speed Vertical Juice Sauce Round Bottle Self-Adhesive Labeling Machine

$7,800.00

Tax included. Shipping calculated at checkout.

VK-VRL-H vertical round bottle labeling machine to achieve a reasonable production goals and design. The labeling process is automatic operation, simple operation, fast production speed, uniform labeling location, beautiful, neat, applicable to pharmaceutical, chemical, food and other industries, circular containers labeling, full circle and semi-circle labeling can be affixed. Optional ribbon printer and inkjet printer, label printing production batch number, production date and other information. Realize the integration of label and sort code, reduce packaging process, improve production efficiency.

Output Speed: 100-400 pieces/minute depends on label and product size

Dimension: (L)2400*(W)1200*(H)1400(mm)

View Video Download PDF

Description

This labeling machine is based on VK-VRL and replaces the labeling engine to achieve a higher labeling speed. This labeling machine is also suitable for various round containers, bottles, cans, jars etc.

This machine has high working speed when compared with similar labeling machines, it can label 100-400 bottles/min. This labeling machine is suitable for single side labeling on round bottles like essential oil, shampoo, jam jar and can realize automated production when working with automatic filling and capping machine. It is widely used in food, daily chemical, and cosmetics industries.

Application

Paramenters

| Model | VK-VRL-H |

| Labeling Speed(pcs/min) | 100-400(relate to product and label size) |

| Labeling Accuracy(mm) | ±1.0mm |

| Suitable Label Size(mm) | (L)10-250mm (H)10-110mm |

| Suitable Product Size | Diameter: 10-100mm, H:20-300mm |

| Roll Inside Diameter(mm) | Φ76mm |

| Rollouter Diameter(mm) | Φ420mm |

| Machine Size(mm) | (L)2400*(W)1200*(H)1400(mm) |

| Power Supply | AC220V50Hz/60Hz/980W |

| Operation Direction | Left To Right Or Right To Left |

| Net Weight | About 350Kg |

| Label Material | Self-Adhesive Sticker, Opaque Or Transparent Label |

Details

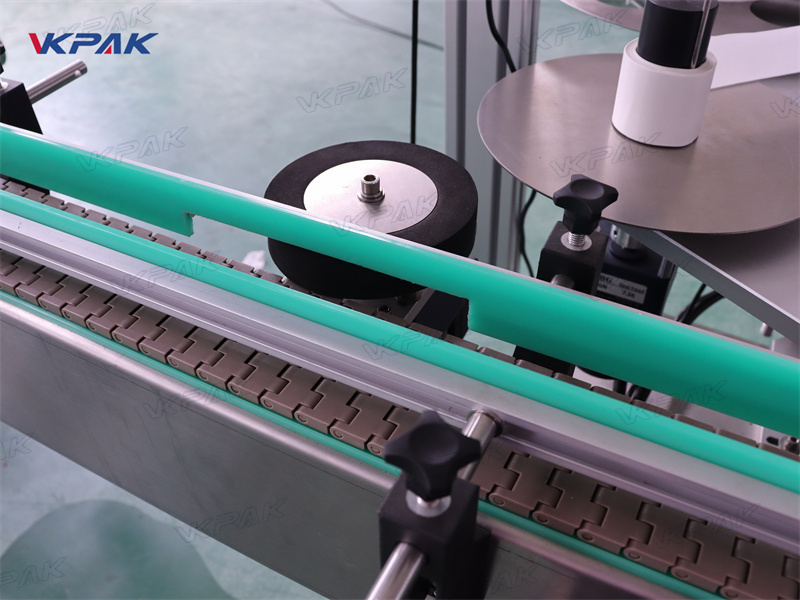

VK-VRL-H Bottle Queuing Wheel

The bottle queuing wheel organizes and spaces bottles accurately before they enter the labeling area, ensuring smooth and continuous flow. This component helps prevent bottlenecks, allowing the labeling machine to maintain an efficient production pace and reducing misalignment issues. The feeding screw can be selected according to the bottle.

VK-VRL-H Coding Machine

The coding machine applies essential information, like batch numbers or expiration dates, onto the labels before they are applied to the bottles. This device is optional.

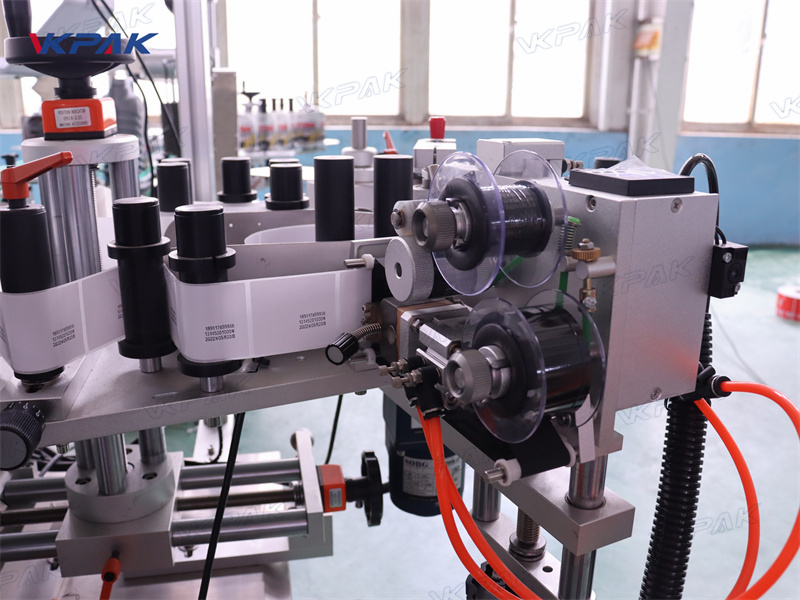

VK-VRL-H Label Peeler Knife and Rolling Mechanism

The Label Peeler Knife and Rolling Mechanism separates labels from the backing paper and positions them for application onto the bottles. By facilitating a smooth and efficient peeling process, this mechanism minimizes label waste and ensures that each label is applied cleanly and accurately, enhancing the overall quality of the final product.

VK-VRL-H Label Pulling Mechanism

This label pulling mechanism pulls labels from the roll smoothly and feeds them towards the labeling head. It ensures a consistent tension and steady label flow, reducing the chance of jams or misfeeds. This mechanism allows for precise label application and is essential for maintaining continuous, high-speed operation.

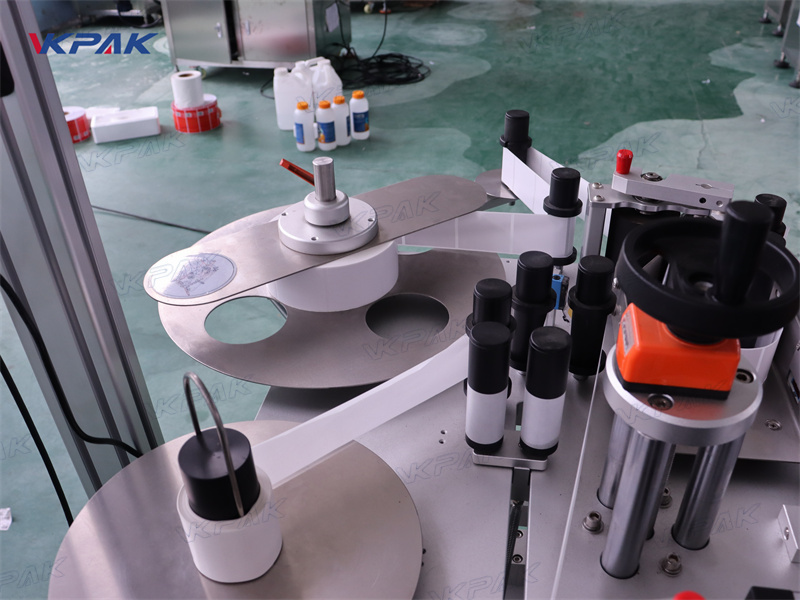

VK-VRL-H Label Roll Tray

The label roll tray holds the roll of labels securely in place and allows it to unwind as needed. It is designed to support various roll sizes, making the machine versatile for different labeling requirements. Its sturdy design helps maintain stability and prevents label roll misalignment during operation.

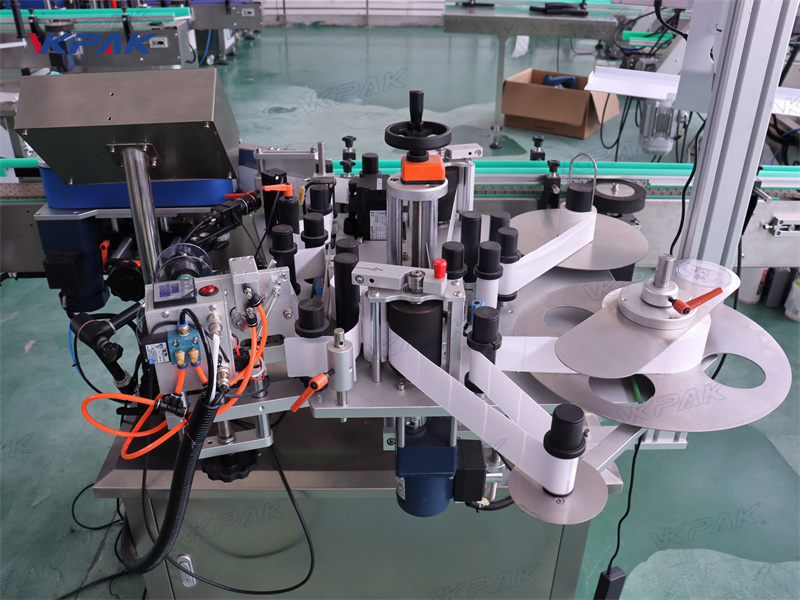

VK-VRL-H Labeling Head

Labeling head is responsible for placing labels onto products with high accuracy. Its flexibility allows it to adjust to different label sizes and shapes, contributing to efficiency and high-quality label application on a range of product surfaces.

You must be logged in to post a review.

Reviews

There are no reviews yet.