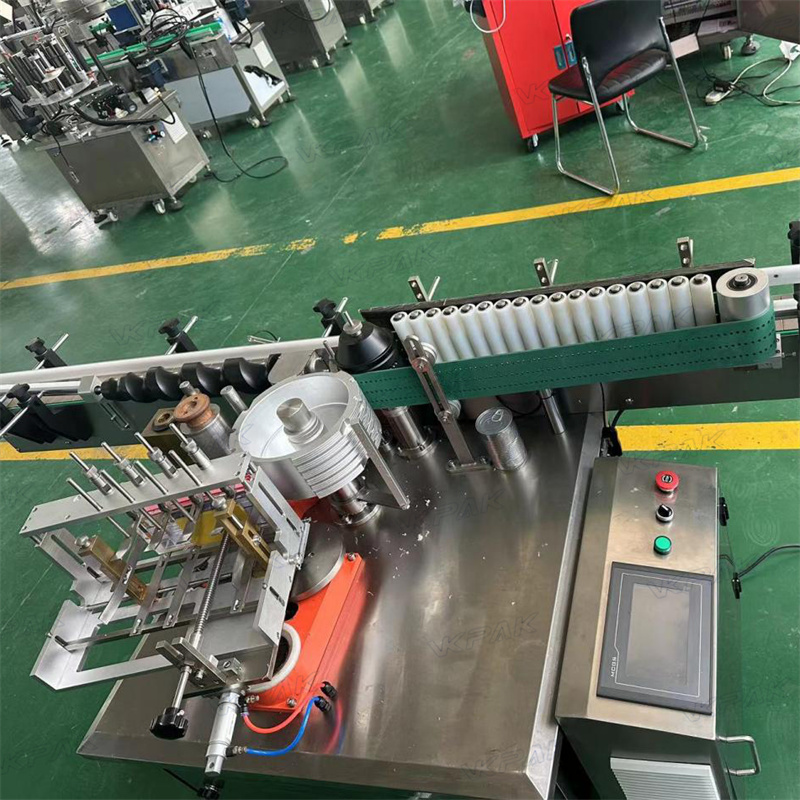

VK-WGL Automatic Linear Bottle Jars Cans Cold Wet Glue Paste Paper Labeling Machine

$9,700.00

Tax included. Shipping calculated at checkout.

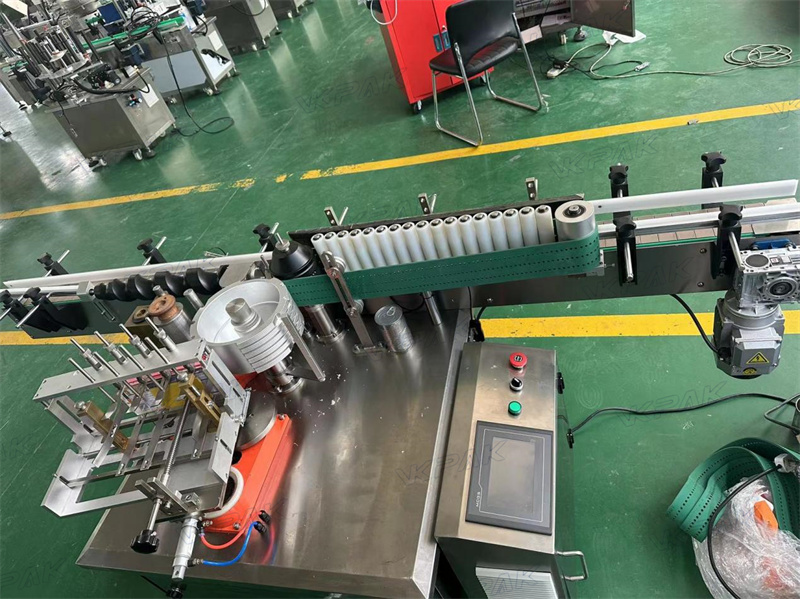

This labeling pasting machine is designed for pasting wet glue labels on round objects like cans, beverage bottle, jam bottles,hot sauce bottles.It is economical and easy to operate. Stable performance, smooth and good labeling effect. When the machine is running, the glue sent from the paste container and the label are firstly pasted by the sticking pole, rotated to the labeling belt, and finally glued around the bottle body. It is widely used in food, daily chemical industries.

Cam work with automatic filling & capping machine to realize automated production.

High labeling accuracy, improves production quality.

Output Speed: 60-150 pieces/minute depends on label and product size

Dimension: (L)2400*(W)950*(H)1000(mm)

View Video Download PDF

Description

This automatic bottle glue labeling machine is designed for labeling paper label on cans, jars, bottle and any kinds of round container. Operator need to put paper labels into label box, and the machine will label stickers automatically. The wet glue is the resin glue. This machine is mianly for the food, chemical industry.

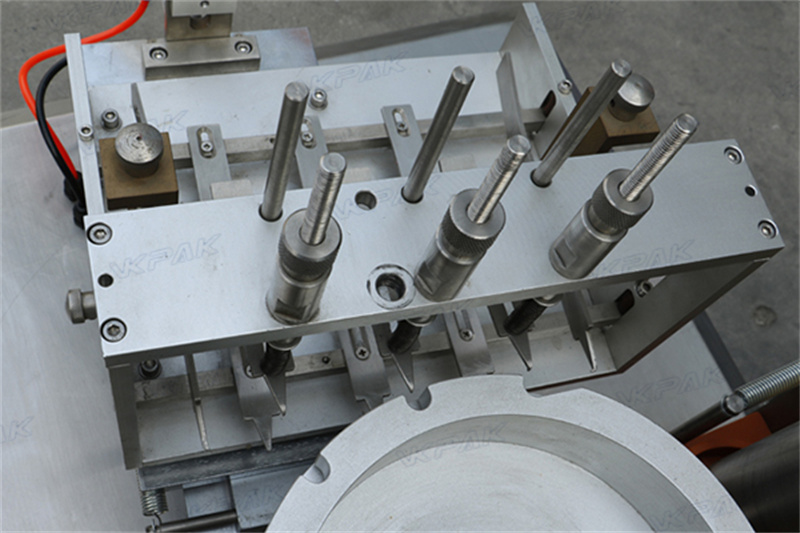

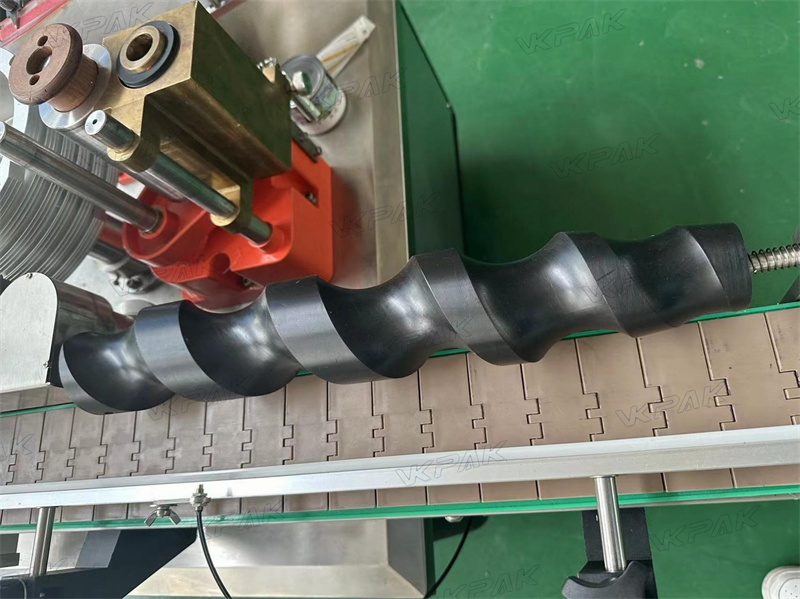

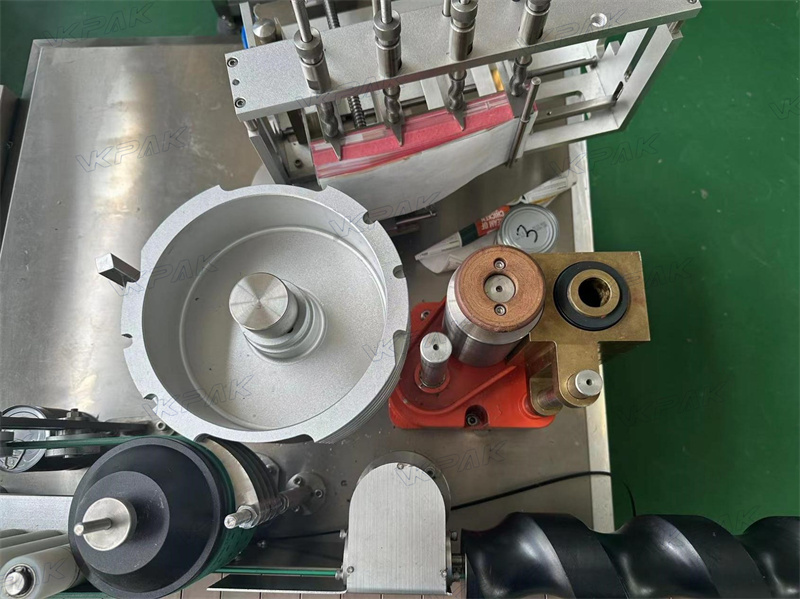

This structure is used to storage labels and it will move left and right when the machine start to work,in this way,labels will be glued one by one.

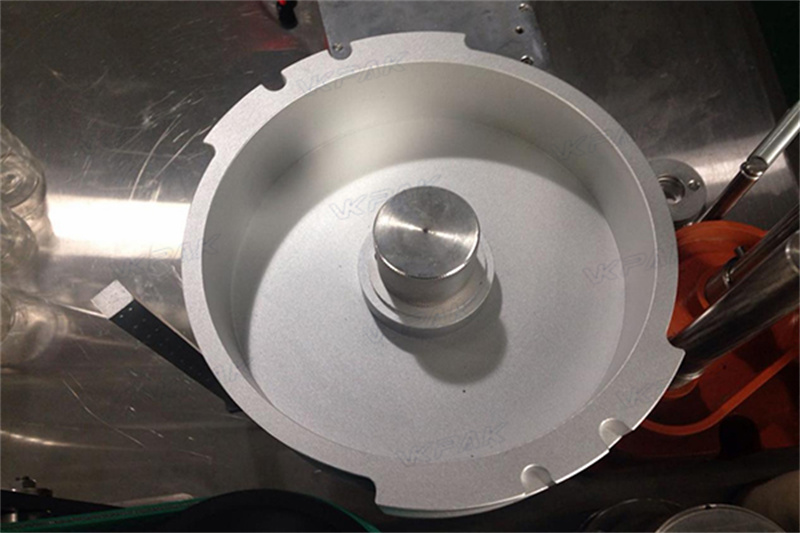

The right side of the copper container is used to storage glue. The “A” transitional roller will help to glue the “B” rubber roller, and the rubber roller can make the middle rotary plate be glued evenly, improves labeling quality.

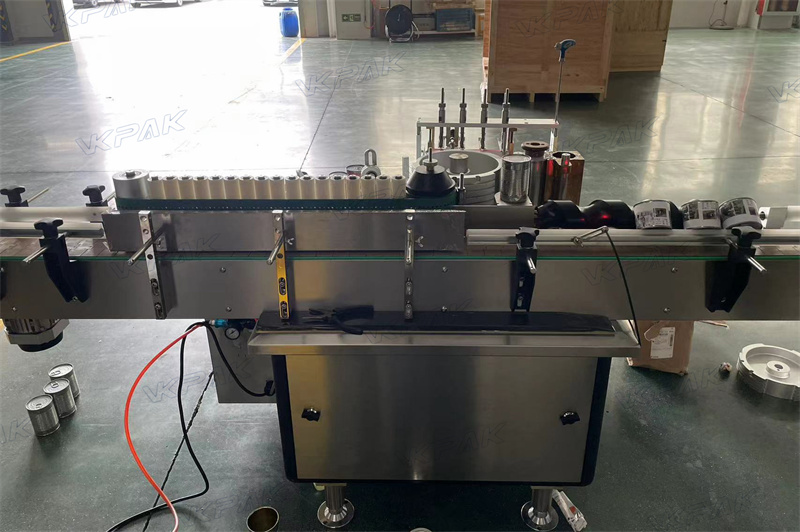

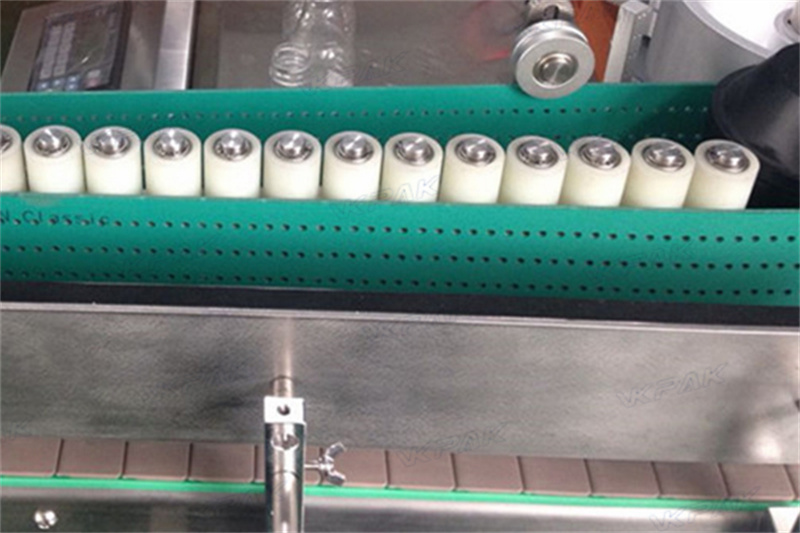

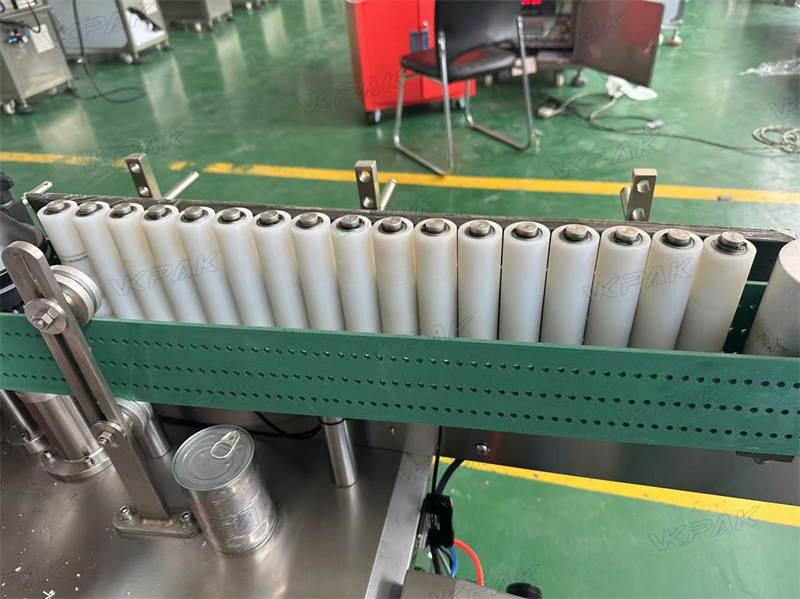

The pressing belt is designed for pressing label sticker and make sure there is no bubble under label stickers. This improves labeling accuracy.

The chain convey is with large weight capacity, it can transport bottles smoothly, reduce production error and improves working speed.

Paramenters

| Model | VK-WGL |

| Labeling Speed(pcs/min) | 60-150(relate to material and label size) |

| Labeling Accuracy(mm) | ±1.0mm(material and label sizes are not counted in) |

| Lable Size(mm) | (L)50-130mm (H)40-110mm |

| Bottle Size(mm) | Φ25-100mm |

| Adhesive | Polyvinyl Acetate Emulsion |

| Working Pressure | 0.4-0.6Mpa |

| Machine Size(mm) | (L)2400*(W)950*(H)1000(mm) |

| Power Supply | AC220V 50/60HZ 1500W |

Application

The whole machine is made of high quality components, durable and simple maintenance. The space of the equipment is small and easy

to move. It can be used on a single machine or with a production line.

Use of servo (PLC) system control, the whole machine is highly automated. The labelling speed is 60-100 pieces per minute, and the

labeling accuracy is +/-1mm.

The whole machine labeling process is simple. Label evenly coated with cold glue, refuse to waste, label firmly and not fall off,

no wrinkle, ribbon stripes, beautiful appearance.

Equipped with touch screen in Chinese and English, all kinds of parameters can be adjusted, and all kinds of functions can be

configured to facilitate production management.

Features:

1. The paste tank is matched with a stainless steel roller and is precisely processed to allow the glue to be taken at any time without leakage;

2. The special rubber roller has been processed through several processes, so it does not deform and is wear-resistant. The glue is uniform and thin, saving glue consumption;

3. Use vacuum label suction and belt, and the label can be smoothly pasted on the bottle;

4. Photoelectric detection of bottles. If there is no bottle, the standard will not be issued;

5. Using the frequency converter, the motor running speed can be freely adjusted and the labeling capacity can be freely controlled.

6. It can operate independently or be connected to the production line;

7. Equipped with manual adjustment device, easy to adjust and operate;

8. By replacing a small amount of sticky rods, vacuum belts and other parts, bottles that meet various specifications can be quickly adjusted. It can eliminate human adjustment factors to the greatest extent;

9. The processing technology of the whole machine is precise and delicate, and the basic parts are all standard parts, which is convenient for maintenance and repair;

10. The whole machine is basically imported configuration to ensure quality, making it more stable, longer in use and low in maintenance rate.

VK-WGL Configuration List

| No. | Name | Model | Qty. | Brand |

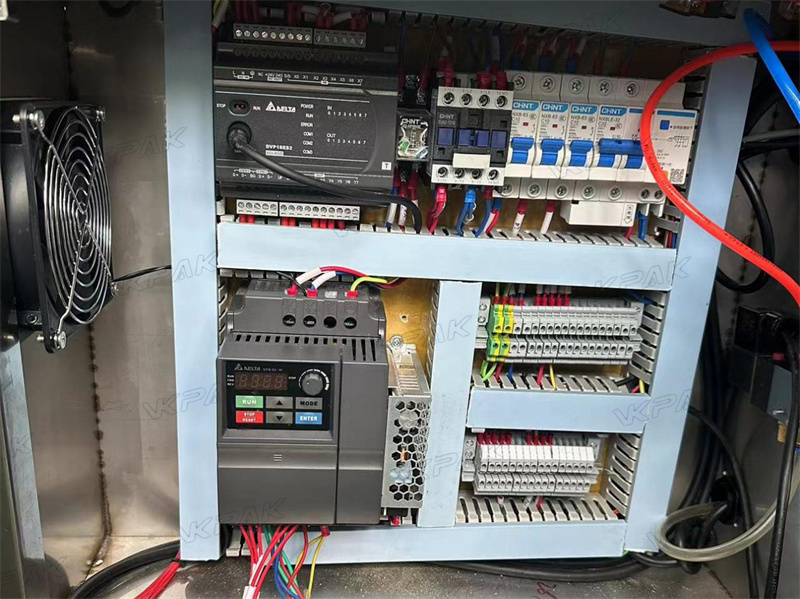

| 1 | Touch screen | TP04P-16TP1R | 1 | DELTA |

| 2 | Frequency converter | VFD015EL21A | 1 | DELTA |

| 3 | communication cable | DVP-VFD-485 | 1 | |

| 4 | DC24V Power | PMC-24V035W1AA | 1 | DELTA |

| 5 | Detect sensor with object | FS-N18N | 1 | Japan Keyence |

| 6 | Reflective fiber | FU-35FA | 1 | Japan Keyence |

| 7 | switch | ISS 212MM/2NO-4NO | 1 | Germany Leuze |

| 8 | electromagnetic valve | 4V110-06 DC24V | 1 | AIRTAC |

| 9 | Air source processor | AFR2000 | 1 | AIRTAC |

| 10 | cylinder | MAL25-25 | 1 | AIRTAC |

| 11 | Relay | LY2N-J(24V DC) | 1 | Japan Omron |

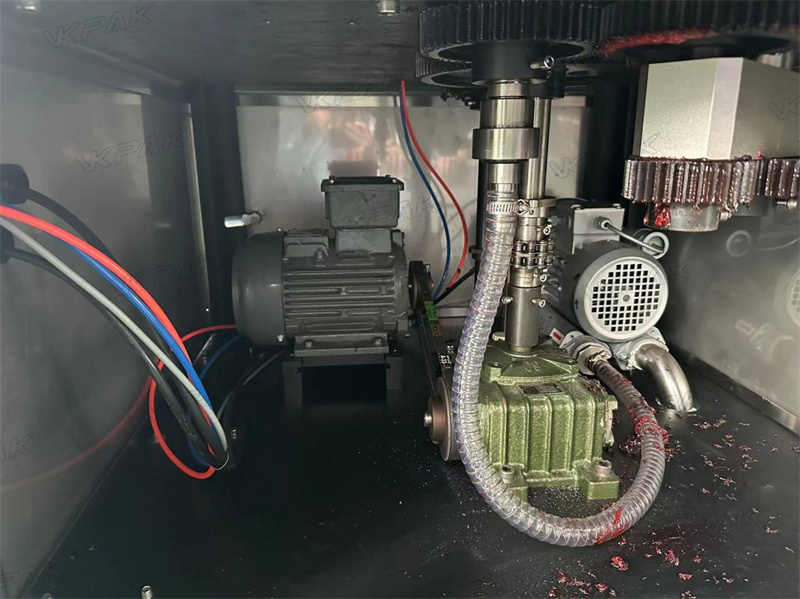

| 12 | Transport motor | 0.12KW, 1:20 | 1 | Zhengjiang JinNong |

| 13 | Motor | AEAVVS0400017M4-A(0.75KW/220V) | 1 | TaiWan DECO |

| 14 | Reducer | VW60 / 30-A | 1 | TaiWan DECO |

| 15 | Fan | TYPE EHS-229 | 1 | EMORE HONE |

| 16 | switch | ZB2-BE101C | 1 | France Schneider |

| 17 | Emergency stop switch | ZB2-BE102C | 1 | France Schneider |

| 18 | air switch | DZ47-63 | 1 | PEOPLE |

| 19 | Alarm | AD16-22SM | 1 | AMPUTE |

| 20 | Fuses | RT18-2A | 3 | Shanghai HUGONG |

You must be logged in to post a review.

Reviews

There are no reviews yet.